Polyurethane with intrinsic conduction and preparation method and application of polyurethane

A polyurethane and polyisocyanate technology, applied in the field of sensors, can solve the problems of price and biological safety constraints, and achieve the effect of less process equipment, excellent electrical conductivity, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) The raw materials used for conductive polyurethane in the present embodiment are composed of the following, in molar weight:

[0053]

[0054] (2) The preparation steps are as follows:

[0055] 1) Mix the polyol with the ions to dissolve the ions in the diol;

[0056] 2) Mixing the ion-dissolving polyol and polyisocyanate while adding a crosslinking agent and adding a catalyst;

[0057] 3) Pour into a mold and polymerize at 70°C for 1 hour to solidify and form conductive polyurethane.

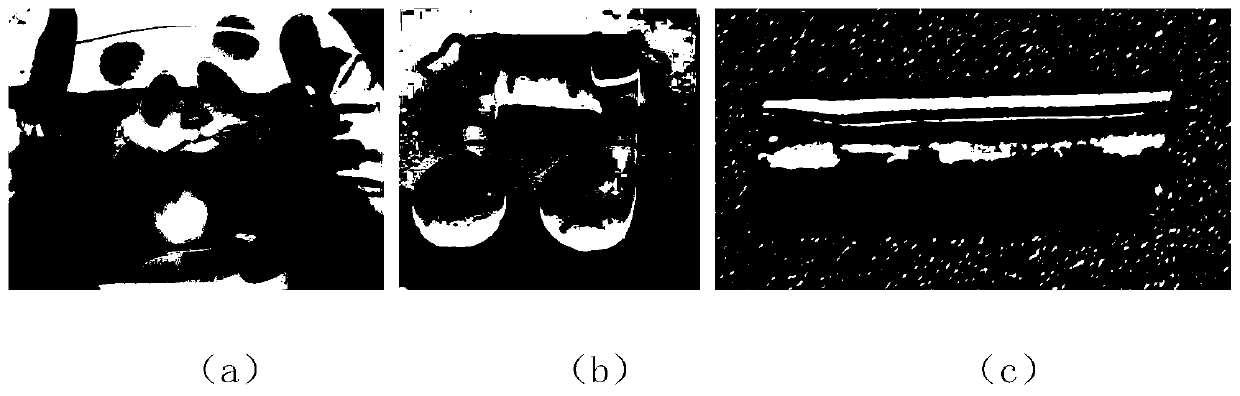

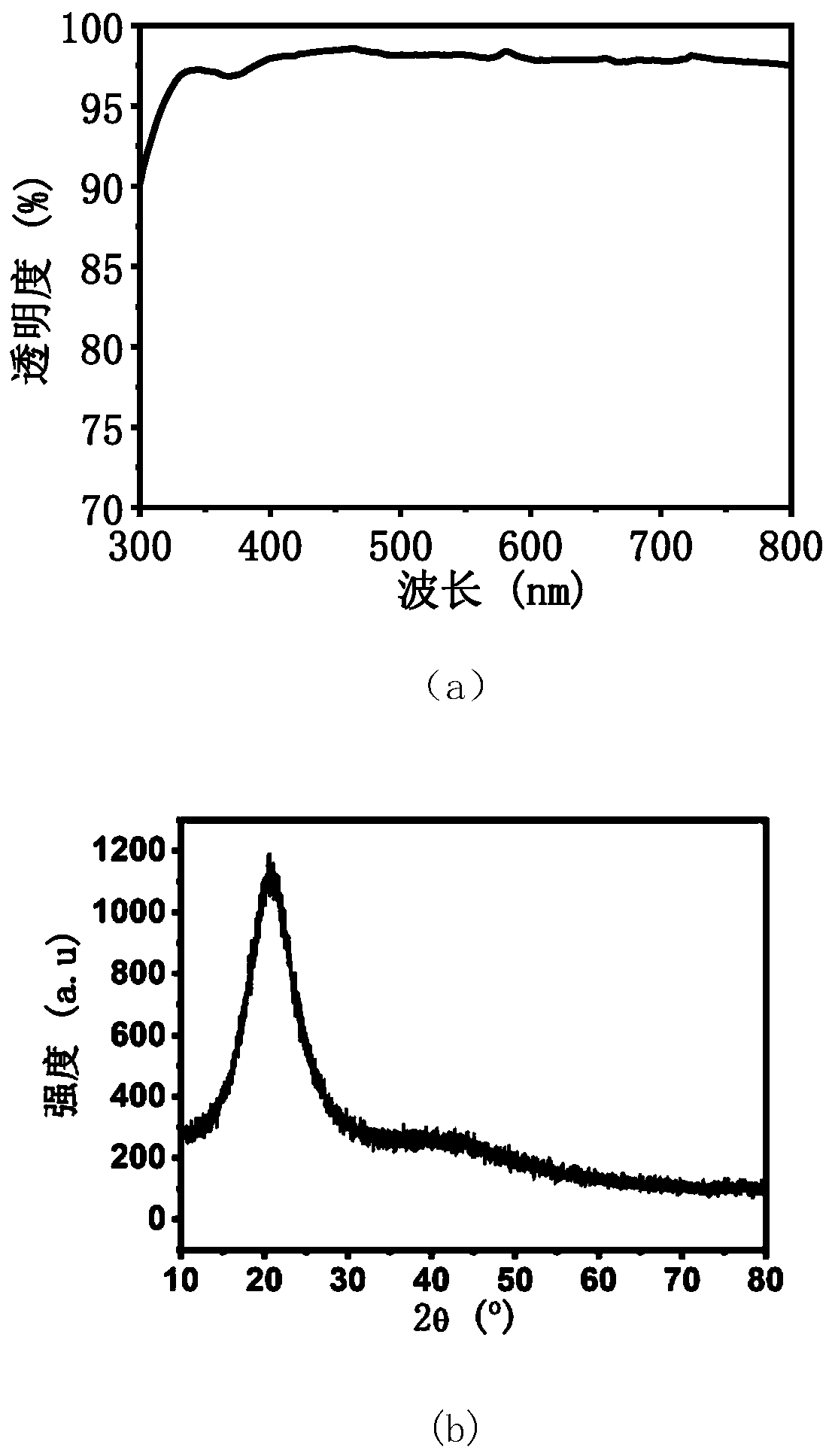

[0058] The oval conductive polyurethane prepared by the present invention, such as figure 1 (a) shown. Such as figure 2 (a) with figure 2 Shown in (b), it is the ultraviolet-visible absorption spectrum and X-ray diffraction pattern of conduction polyurethane, by figure 2 (a) with figure 2 (b) It can be seen that the absence of ionic crystals can be clearly seen, indicating that the conductive polyurethane of the present invention does not absorb visible light, and has t...

Embodiment 2

[0060] (1) The difference between this embodiment and the present invention's embodiment 1 is that the amount of ions used is different, and the raw materials used for conductive polyurethane in the present embodiment are composed of the following:

[0061]

[0062] (2) The preparation method is the same as that in Example 1 of the present invention to form conductive polyurethane.

[0063] The musical note-shaped conductive polyurethane prepared by the present invention, such as figure 1 (b) shown.

Embodiment 3

[0065] (1) The difference between this embodiment and the present invention's embodiment 1 is that the amount of ions used is different, and the raw materials used for conductive polyurethane in the present embodiment are composed of the following:

[0066]

[0067] (2) The preparation method is the same as in Embodiment 1 of the present invention, forming conductive polyurethane

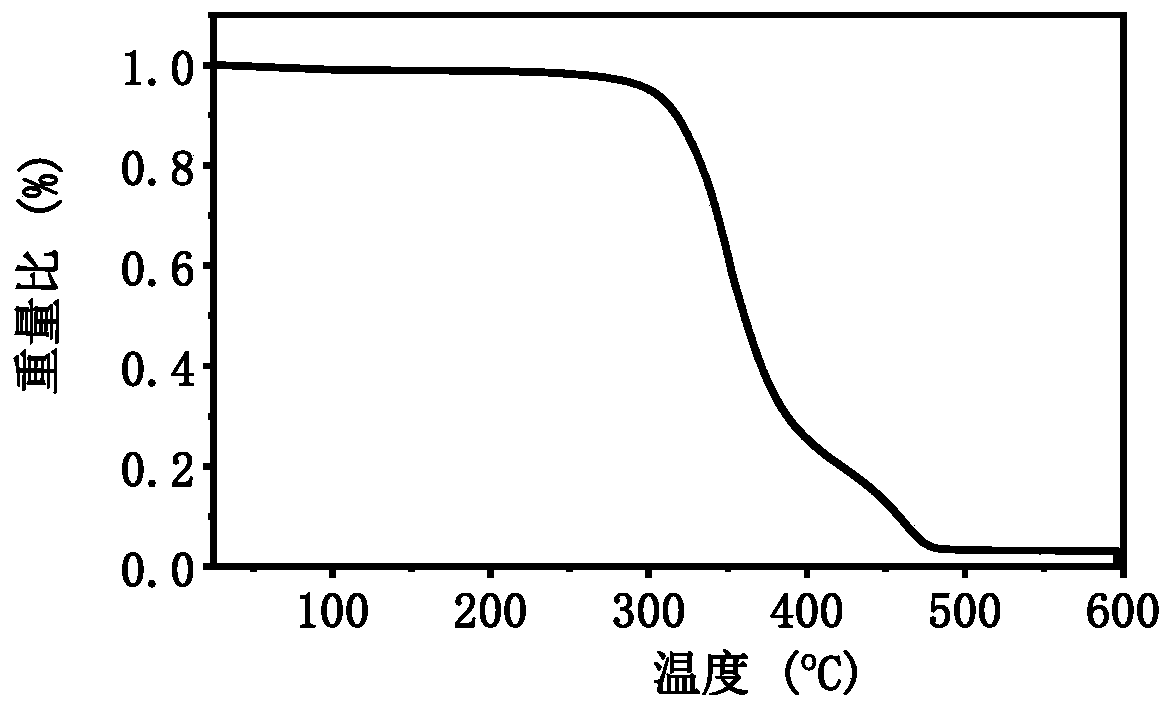

[0068] Above-mentioned embodiment of the present invention 1-3 gained resistance is as Figure 4 As shown, the conductive polyurethane has good electrical conductivity, and the conductivity of the conductive polyurethane can be controlled by adjusting the amount of ions added.

[0069] The conductive polyurethane of the pipeline prepared by the present invention, such as figure 1 (c) shown.

[0070] In summary, through figure 1 It can be seen that the polyurethane prepared in the present invention can be polymerized into any shape.

[0071] Implementation column 4,

[0072] (1) The differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com