A kind of biological nd-zn alloy and preparation method thereof

A biological and alloy technology, applied in the directions of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of insufficient mechanical strength and low sintering density, and achieve improved mechanical properties, enhanced mechanical properties, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using an electronic balance to weigh 9.2g of zinc powder with a particle size of 17 to 53 μm and 0.8g of rare earth Nd powder with a particle size of 5 to 10 μm, mix them by ball milling under the protection of high-purity argon, and control the ball milling speed so that the ball milling speed is 240r / min, the ball milling time is 1h, finally get uniform Nd-Zn alloy powder.

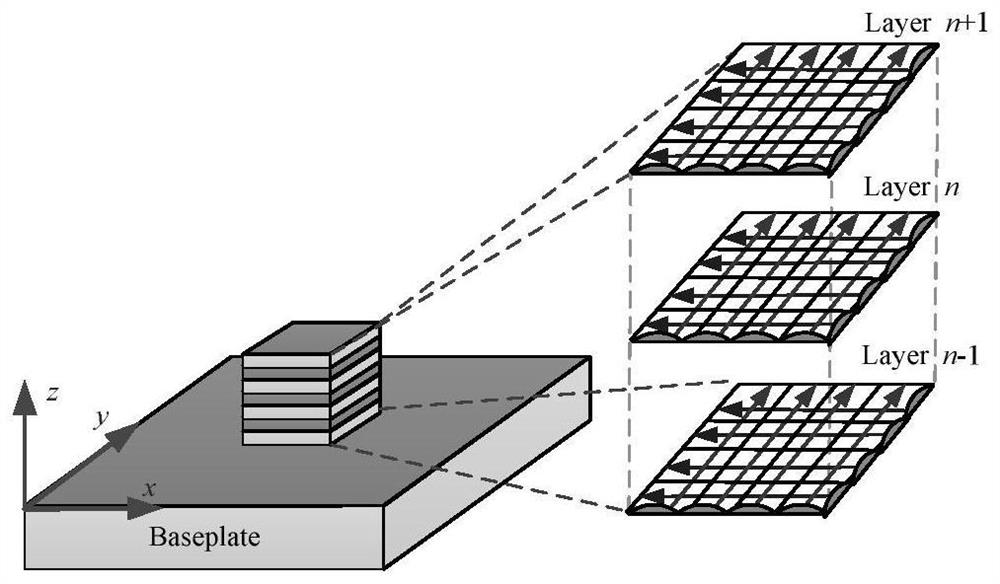

[0036] Put the Nd-Zn alloy powder in the laser selective melting forming system, and perform layer-by-layer laser melting and sintering according to the three-dimensional model. Firstly, spread the first layer of Nd-Zn alloy powder on the substrate of the laser selective melting forming system , scanning in the X direction of the laser in turn, and then scanning in the Y direction to obtain a single-layer sintered body, and then repeat the above scanning strategy to obtain a biological Nd-Zn alloy. The specific forming process parameters are: laser power 95W, scanning speed 230mm / s, the scanning ...

Embodiment 2

[0043] Use an electronic balance to weigh 9.5g zinc powder with a particle size of 17-53μm and 0.5g rare earth Nd powder with a particle size of 5-10μm, and ball mill the mixed powder under the protection of high-purity argon. The ball milling speed is 260r / min. The time is 1.5h, and finally a uniform Nd-Zn alloy powder is obtained by grinding.

[0044] Put the Nd-Zn alloy powder in the laser selective melting forming system, and perform layer-by-layer laser melting and sintering according to the three-dimensional model. Firstly, spread the first layer of Nd-Zn alloy powder on the substrate of the laser selective melting forming system , scanning in the X direction of the laser in turn, and then scanning in the Y direction to obtain a single-layer sintered body, and then repeat the above scanning strategy to obtain a biological Nd-Zn alloy. The specific forming process parameters are: laser power 95W, scanning speed 230mm / s, the scanning distance is 60 μm, the spot diameter i...

Embodiment 3

[0051] Use an electronic balance to weigh 9.0g of zinc powder with a particle size of 17-53μm and 1.0g of rare earth Nd powder with a particle size of 5-10μm, and ball mill the mixed powder under the protection of high-purity argon. The ball milling speed is 280r / min, and the ball milling The time is 1h, and finally a uniform Nd-Zn alloy powder is obtained by grinding.

[0052] Put the Nd-Zn alloy powder in the laser selective melting forming system, and perform layer-by-layer laser melting and sintering according to the three-dimensional model. Firstly, spread the first layer of Nd-Zn alloy powder on the substrate of the laser selective melting forming system , scanning in the X direction of the laser in turn, and then scanning in the Y direction to obtain a single-layer sintered body, and then repeat the above scanning strategy to obtain a biological Nd-Zn alloy. The specific forming process parameters are: laser power 95W, scanning speed 230mm / s, the scanning distance is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com