Nano preservative film with intelligent response and antibacterial functions and preparation method thereof

A nano-preservation film, functional technology, applied in the direction of rayon manufacturing, textile and paper making, single-component polyester rayon, etc., to achieve the effect of extending the validity period, good economic and social benefits, and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Another object of the present invention is to provide a method for preparing the above-mentioned nano cling film. The preparation method includes the following steps:

[0031] S1) Preparation of the shell solution: mixing polylactic acid-glycolic acid copolymer, ethylene-vinyl alcohol copolymer, N,N-dimethylacetamide and ethanol to obtain a uniform solution;

[0032] S2) Prepare the core layer solution: dissolve thymol in absolute ethanol, and stir at room temperature until thymol and absolute ethanol are completely miscible to obtain a uniform solution;

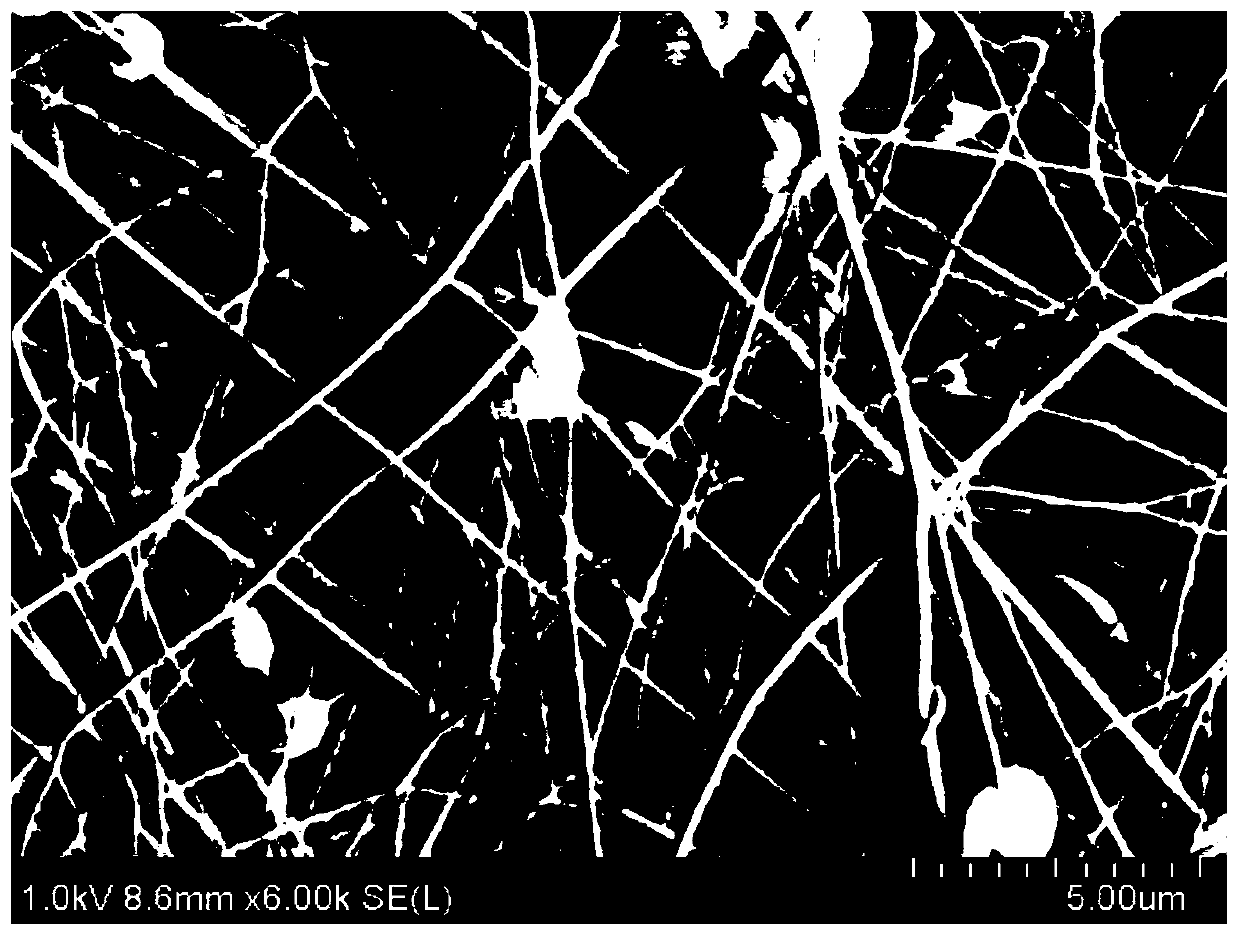

[0033] S3) The solution obtained in S1) and the solution obtained in S2) are used to prepare an ultrafine fiber membrane with a core-shell double-layer structure, that is, a nano cling film by coaxial electrospinning technology.

[0034] Further, the volume ratio of N,N-dimethylacetamide to ethanol in S1) is 1:1 to 1:6.

[0035] Further, the ratio of polylactic acid-glycolic acid copolymer and ethanol in said S1) is 1:1-1:3.

[...

Embodiment 1

[0041] The electronic balance weighed 3g EVOH (32% ethylene content) into 27g DMAc, and magnetically stirred at 90°C until the solution was completely dissolved to obtain a 10% mass fraction shell solution.

[0042] Place the reagent bottle containing the above-mentioned shell solution in an ultrasonic cleaner and ultrasonic for half an hour, in order to remove bubbles in the electrostatic spinning solution.

[0043] Weigh 5g of thymol on an electronic balance, add it to the already weighed 5g of ethanol, and place it in a shaker to shake well until the thymol is completely dissolved in the ethanol to obtain a 50% thymol solution, which is used as Core layer solution for coaxial electrospinning.

[0044] Carry out coaxial electrospinning, the voltage applied by the high-voltage power supply is 14kV, the flow rate of the shell solution is 0.8ml / h, the flow rate of the core solution is 0.3ml / h, the distance between the needle and the receiving plate is 18cm, and the nanofibers obtained...

Embodiment 2

[0047] The electronic balance weighed 6g EVOH (36% ethylene content) into 34g DMAc, stirred magnetically at 90°C until the solution was completely dissolved, and a shell solution with a mass fraction of 15% was obtained.

[0048] Place the reagent bottle containing the above-mentioned shell solution in an ultrasonic cleaner and ultrasonic for half an hour, in order to remove bubbles in the electrostatic spinning solution.

[0049] Weigh 8g of thymol on an electronic balance, add it to the already weighed 8g of ethanol, and place it in a shaker to shake well until the thymol is completely dissolved in the ethanol to obtain a 50% thymol solution, which is used as Core layer solution for coaxial electrospinning.

[0050] Conduct coaxial electrospinning, the voltage applied by the high-voltage power supply is 16kV, the flow rate of the shell solution is set to 1.0ml / h, the flow rate of the core solution is set to 0.5ml / h, and the distance between the needle and the receiving plate is 15c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com