Heat transfer enhancement alloy hydrogen storage tank

A technology to enhance heat exchange and hydrogen storage tanks, applied in indirect heat exchangers, fixed-capacity gas storage tanks, hydrogen technology, etc., can solve the problems of low heat exchange efficiency and large system occupation volume, and achieve enhanced heat exchange efficiency, Effect of improving hydrogen absorption and desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

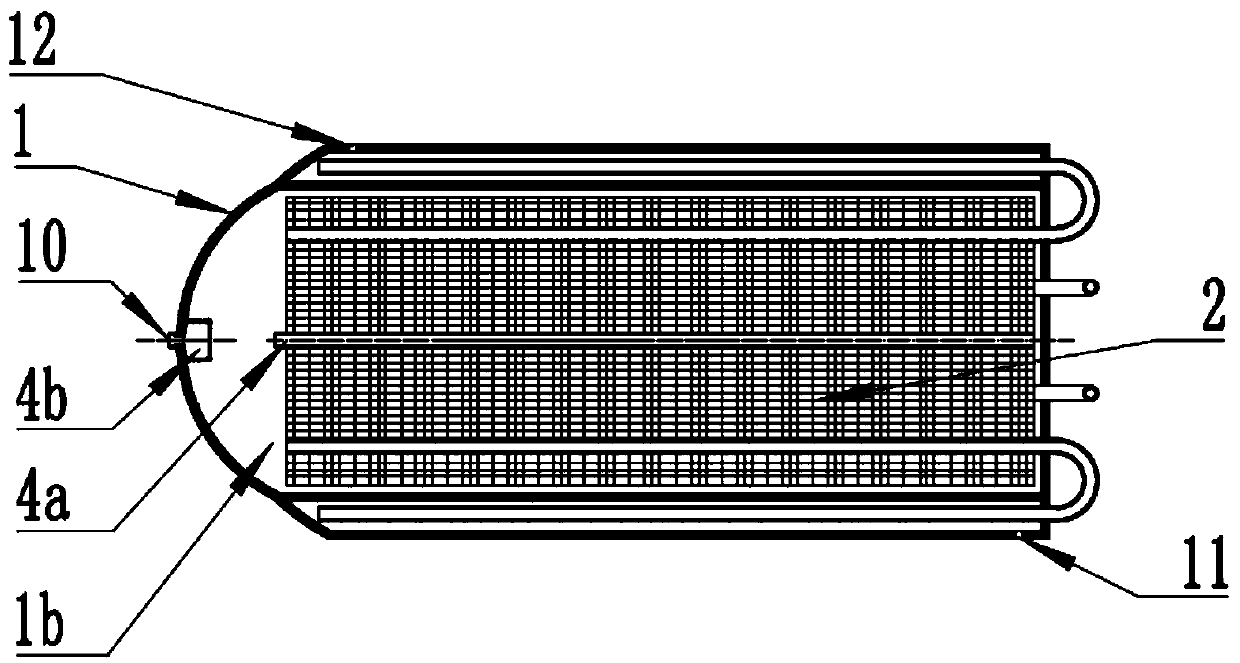

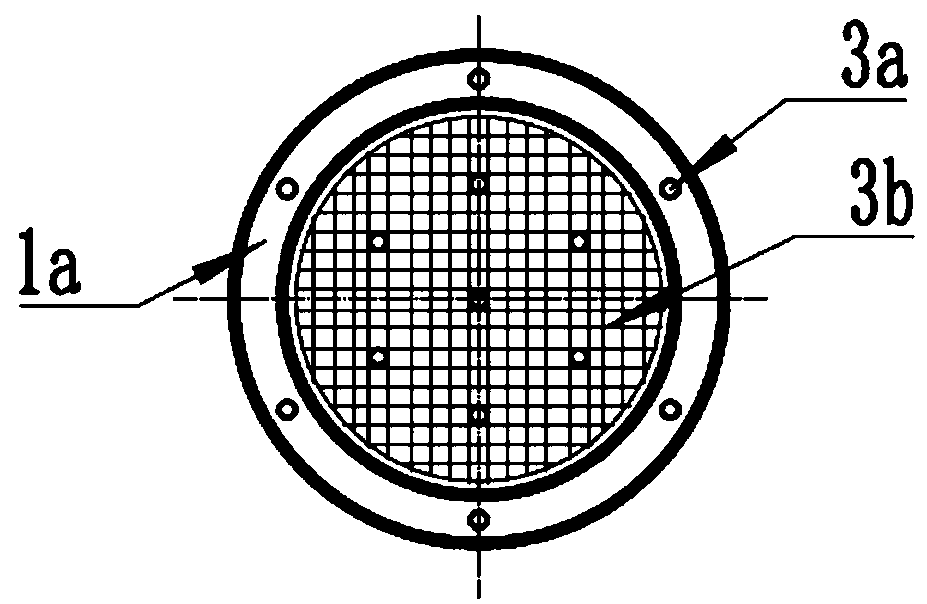

[0027] This embodiment takes the hydrogen absorption and discharge of a titanium-iron alloy hydrogen storage tank as an example. The material of the U-shaped heat pipe 3a shell of the present invention is oxygen-free copper, the liquid-absorbing core is a powder sintered type, and the internal working medium is alcohol or acetone; the material of the tank body 1 is stainless steel, and the heat exchange medium flowing through the outer shell is Hot and cold water.

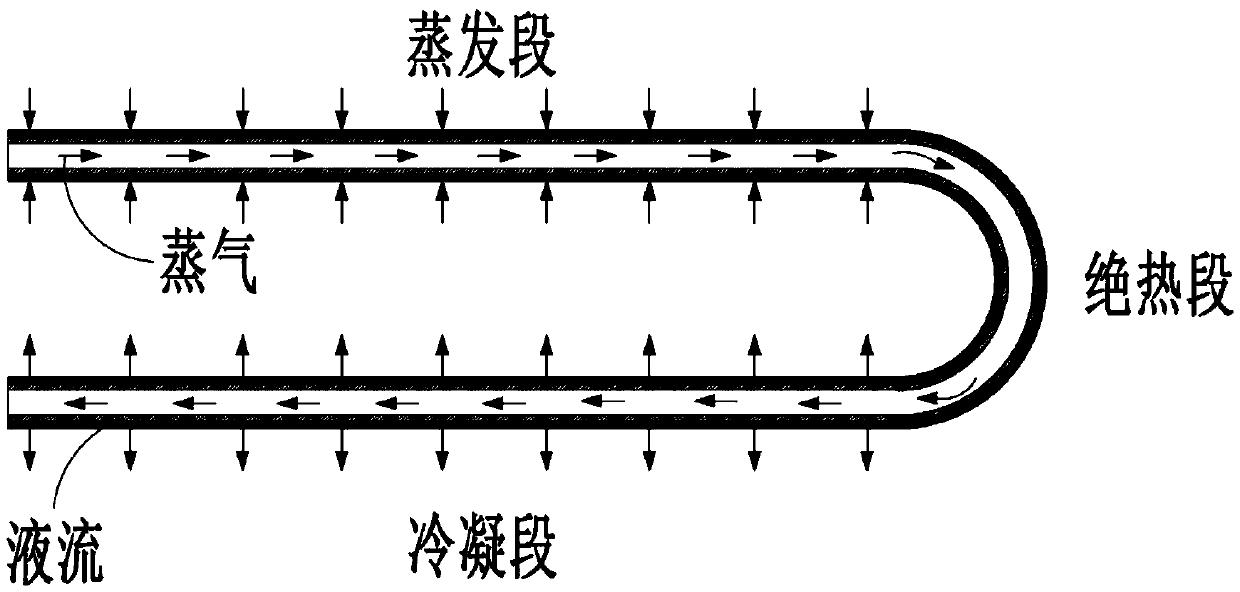

[0028] For the hydrogen filling process, hydrogen enters the gas guide structure 4 from the hydrogen inlet and outlet 10, and the gas enters the alloy powder bed 2 along the filter 4b and the air guide pipe 4a, and chemically reacts with the hydrogen storage alloy in the grid to form alloy powder , releasing a lot of heat. The heat is conducted to the evaporating section of the U-shaped heat pipe 3a through the copper fins of the grid fin 3b, and the working medium in the evaporating section of the heat pipe is ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com