Yttrium-containing misch metal, rare earth hydrogen storage alloy and preparation method of yttrium-containing misch metal and rare earth hydrogen storage alloy

A mixed rare earth and hydrogen storage alloy technology, applied in non-metallic elements, chemical instruments and methods, hydrogen and other directions, can solve the problems of high production cost, large production waste residue, and high product impurity content, so as to reduce production cost and achieve better absorption and release. Hydrogen performance, the effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] An embodiment of the present invention provides a method for preparing yttrium-containing mixed rare earth metals, comprising: performing electrolysis with an electrolyte containing mixed rare earth fluorides, and adding mixed rare earth oxides during the electrolysis; wherein the mixed rare earth fluorides include YF 3 and other rare earth fluorides, mixed rare earth oxides including Y 2 o 3 and other rare earth oxides. The rare earth elements in other rare earth fluorides and other rare earth oxides are generally the same so as not to introduce impurities, and other rare earth oxides are selected from La 2 o 3 and CeO 2 At least one of the other rare earth fluorides selected from LaF 3 and CeF 3 at least one of the

[0023] It should be noted that the inventor creatively utilizes the entrainment effect of low-melting rare earth metals lanthanum and cerium in the electrolysis process, which wraps the solid yttrium after it is generated on the cathode and drops it...

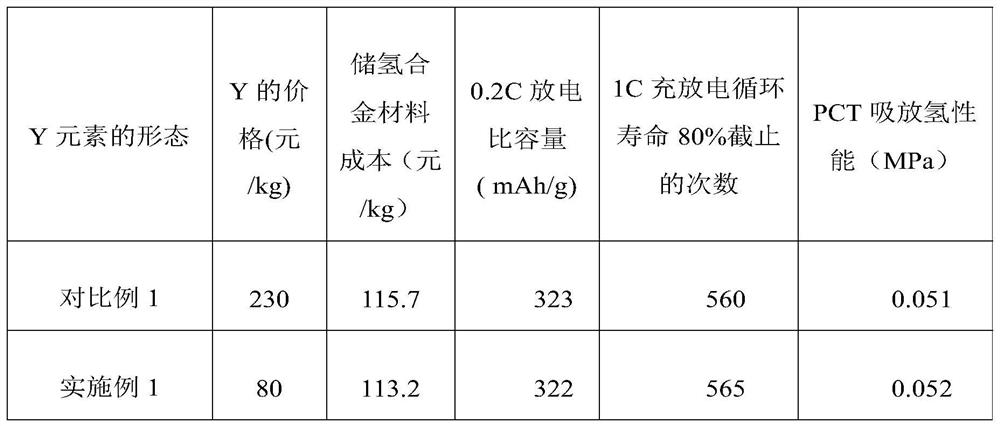

Embodiment 1

[0037] This embodiment provides a kind of mixed rare earth metal YLa containing yttrium 11.6 Ce 4.75 And the preparation method of corresponding rare earth hydrogen storage alloy, comprising the following steps:

[0038] Mixed high-abundance rare earth fluoride (YF 3 :LaF 3 :CeF 3 =1:10:4.1) and lithium fluoride in a ratio of 100:12.5 to make an electrolyte, put it in a 3000A graphite tank for rare earth molten salt electrolysis, and heat it up with an AC arcing machine until the electrolyte is completely melted and the temperature reaches 1000°C ~1050°C, insert a tungsten cathode, and send direct current for electrolysis. Electrolyze for one hour, evenly add 4000kg of lanthanum cerium yttrium mixed oxide (Y 2 o 3 :La 2 o 3 :CeO 2 =1:10.7:4.6), the output contains yttrium mixed rare earth metal YLa 11.6 Ce 4.75 Weighs 3280g.

[0039] 1300g mischmetal YLa containing yttrium 11.6 Ce 4.75 , 2240g metal Ni, 340g metal Co, 180g metal Mn, 90g metal Al and 60g metal Zr ...

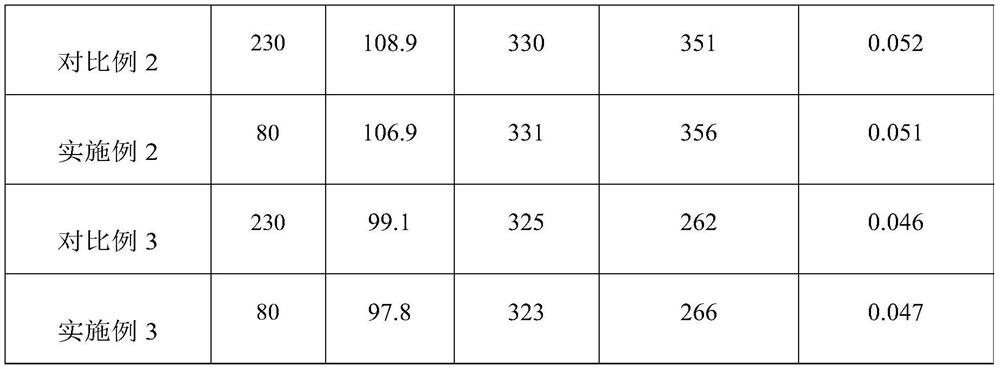

Embodiment 2

[0044] This embodiment provides a kind of mixed rare earth metal YLa containing yttrium 18.7 Ce 4.1 And the preparation method of corresponding rare earth hydrogen storage alloy, comprising the following steps:

[0045] Mixed high-abundance rare earth fluoride (YF 3 :LaF 3 :CeF 3 =1:16.1:3.5) and lithium fluoride in a ratio of 100:11.8 to make an electrolyte, put it in a 3000A graphite tank for rare earth molten salt electrolysis, and heat it up with an AC arcing machine until the electrolyte is completely melted and the temperature reaches 1000°C -1080℃, insert tungsten cathode, send direct current for electrolysis. Electrolyze for one hour, evenly add 4000g of lanthanum cerium yttrium mixed oxide (Y 2 o 3 :La 2 o 3 :CeO 2 =1:17.2:4.6), the output of mixed high-abundance rare earth metal YLa 18.7 Ce 4.1 Weighs 3315g.

[0046] 1300g mischmetal YLa containing yttrium 18.7 Ce 4.1 , 2500g metal Ni, 155g metal Co, 150g metal Mn, 95g metal Al and 6g metal Zr are used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com