Preparation method of grain-albumin-free soy sauce, and grain-albumin-free soy sauce

A technology of grain protein and soy sauce, applied in food science and other directions, can solve the problems of insufficient sauce flavor, low protein content, low utilization rate of raw materials, etc., and achieve the effect of delicious taste, high nutritional value and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

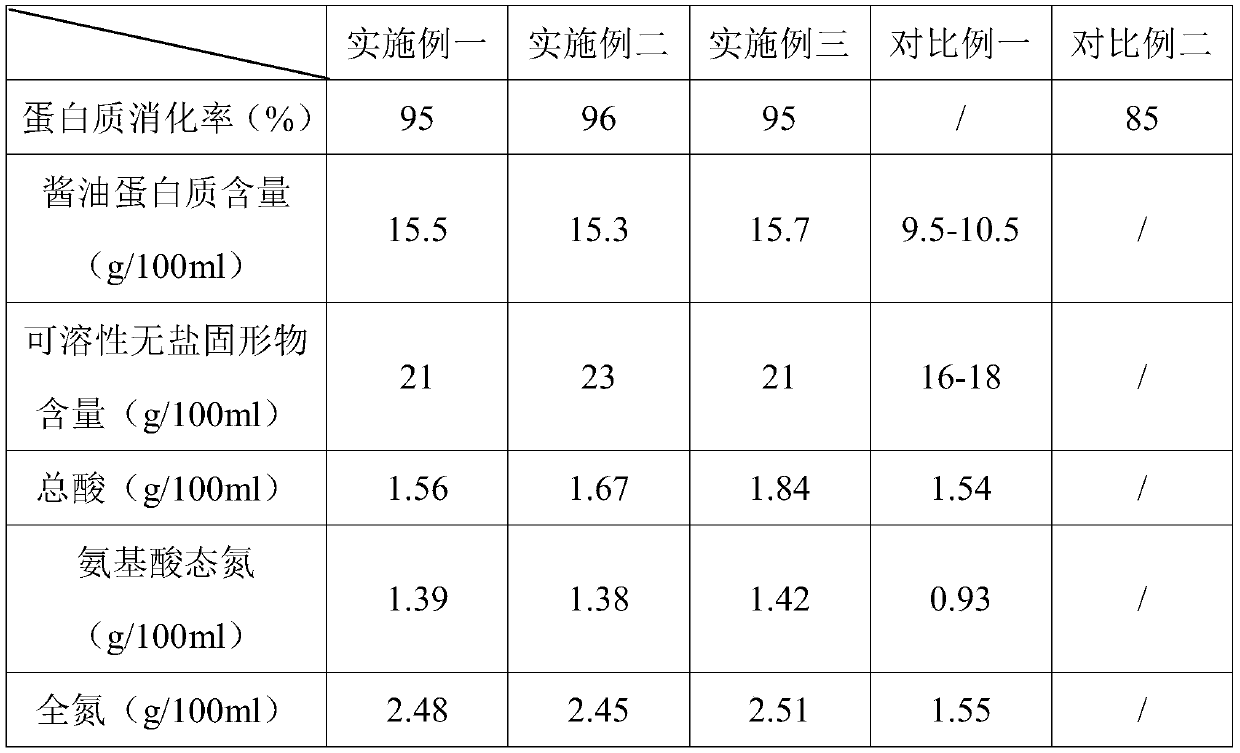

Examples

Embodiment 1

[0022] Weigh 5000kg of soybeans, press them into flakes with a thickness of 3mm, heat them with 0.6Mpa superheated steam for 20s, then quickly depressurize and expand them, and crush them into powder for later use; weigh 10000kg of soybean meal, measure 1.2kL of water to moisten the Cooking in a pot, the cooking temperature is 130°C, and the cooking time is 5min; after cooking, the water mass fraction in the soybean meal clinker is 55-59%; after mixing the soybean meal clinker and soybean powder, inoculate Aspergillus oryzae, the inoculation amount is the total amount of soybean meal and powder. 0.1% of the mass is fermented into the pool to make soy sauce koji; the soy sauce koji is mixed with salt water and pumped into the fermenter, wherein the amount of salt water is 1.2 times the total weight of soy sauce koji; the fermentation process in the fermenter is divided into three consecutive stages: The first stage is to adjust the temperature of the fermenter to 10-17°C, and th...

Embodiment 2

[0024] Weigh 5000kg of black beans, press them into sheets with a thickness of 5mm, heat them with 1.0Mpa superheated steam for 50s, then quickly release the pressure and expand them, and crush them into powder for later use; Cook in a steamer, the cooking temperature is 132°C, and the cooking time is 5min; the moisture mass fraction in the soybean meal clinker after cooking is 55% to 59%; after mixing the soybean meal clinker and defatted soybean powder, inoculate Aspergillus oryzae, the inoculation amount is soybean meal and 0.1 to 0.2% of the total mass of the powder, put into the pool for fermentation to make soy sauce koji; mix soy sauce koji with salt water, and pump it into the fermenter, wherein the amount of salt water is 1.5 times the total weight of soy sauce koji; the fermentation process in the fermenter is divided into Three consecutive stages: the first stage is to adjust the temperature of the fermenter to 17°C, and the fermentation time is 20 days; the second s...

Embodiment 3

[0026] Weigh 4000kg of soybeans, press the soybeans into flakes with a thickness of 3-5mm, heat them with 0.8Mpa superheated steam for 35s, then quickly release the pressure and expand them, and crush them into powder for later use; weigh 10000kg of soybean meal, and measure 1.2-1.3kL of water-moistened soybean meal Then put it into a steamer for cooking, the cooking temperature is 131°C, and the cooking time is 5min; the moisture mass fraction in the soybean meal clinker after cooking is 57%; after mixing the soybean meal clinker and defatted soybean powder, inoculate Aspergillus oryzae, the inoculation amount is soybean meal and 0.15% of the total mass of the powder, put it into the pool for fermentation to make soy sauce koji; mix soy sauce koji with salt water, and pump it into the fermenter, wherein the amount of salt water is 1.3 times the total weight of soy sauce koji; the fermentation process in the fermenter is divided into three Continuous stage: the first stage is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com