Method for preparing square bismuth oxychloride with adjustable thickness through hydrothermal method

A technology of bismuth oxychloride and hydrothermal method, which is applied in chemical instruments and methods, catalyst activation/preparation, oxidized water/sewage treatment, etc., can solve the problems of cumbersome preparation and long time consumption, and achieve simple process, low cost, excellent The effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Preparation of BiOCl photocatalyst with adjustable thickness

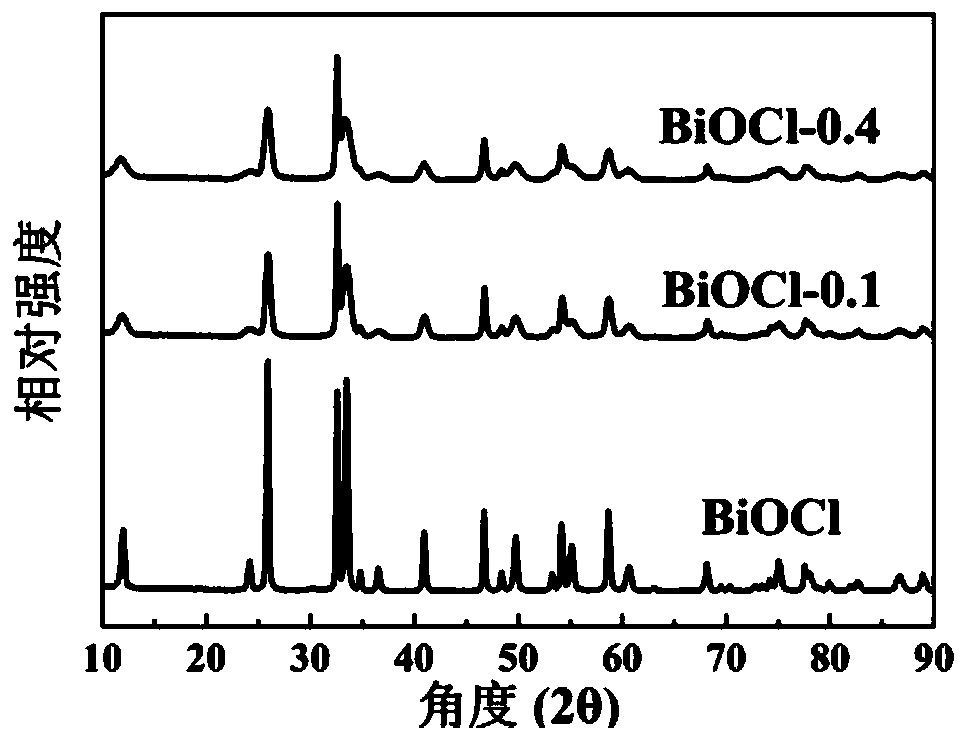

[0019] First disperse 0.9g of mannitol in 60mL of ultrapure water, stir thoroughly to dissolve, then add 0.97g of Bi(NO 3 ) 3 ·5H 2 O was added to it. After stirring for 20 minutes, different amounts of PVP (0, 0.1, 0.4g) were added respectively. After stirring for 10-20 minutes, saturated sodium chloride solution was added. After stirring for 30 minutes, the above homogeneous suspension was transferred to 100mL Teflon-lined stainless steel autoclave, and keep at 160°C for 3 hours. After cooling to room temperature, the obtained precipitate is centrifuged, washed repeatedly with ultrapure water and ethanol, and dried at 80°C to obtain BiOCl with different thicknesses. The BiOCl photocatalyst in the present invention will be determined by X-ray diffraction (XRD), such as figure 1 , The characteristic peaks of BiOCl in XRD can correspond to the standard card 85-0861 one-to-one, and there is no other imp...

Embodiment 2

[0021] Example 2: Photocatalyst visible light degradation of norfloxacin.

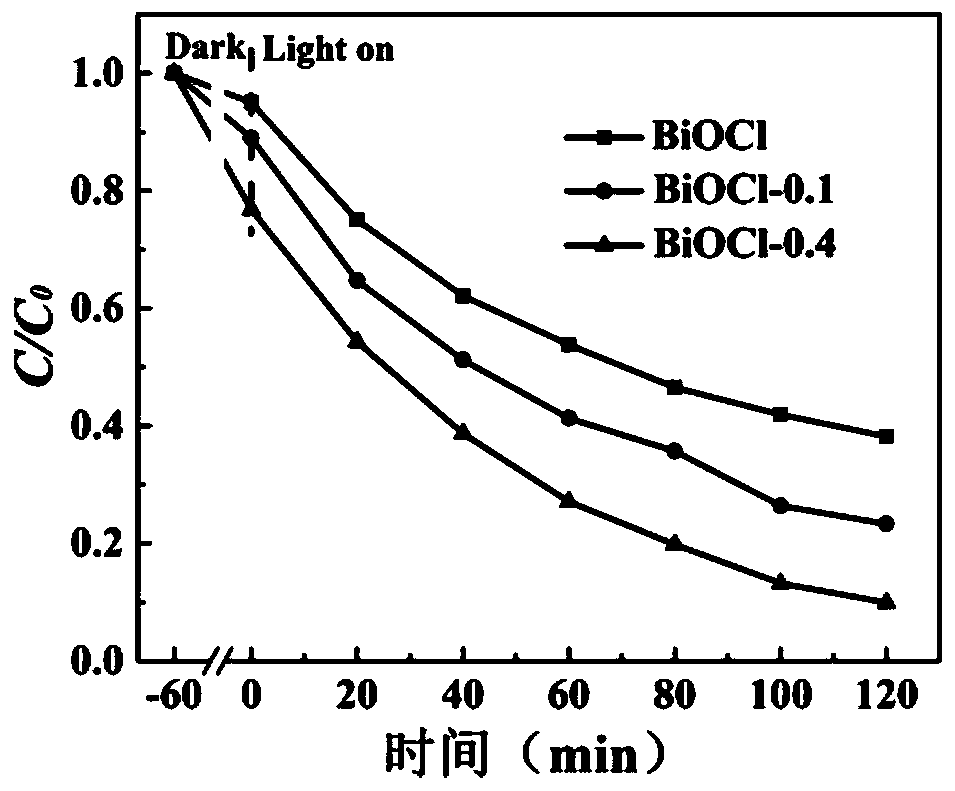

[0022] The photocatalyst samples obtained in the above implementation examples were subjected to an experiment of degrading norfloxacin, and BiOCl with different thicknesses was degraded under visible light for 60 minutes. Take 100 mL of 20 mg / L norfloxacin solution, add 0.05 g of photocatalyst, and put it in the photocatalytic instrument, and react in the dark for 30 minutes before reaching the adsorption-desorption equilibrium. Turn on the light to perform the photocatalytic reaction under visible light. Take 4mL samples every 20min, and immediately pass the solution through a 0.45μm water phase filter. A total of 7 samples were taken, and the concentration of the obtained sample was measured by liquid chromatography. Calculate the removal rate R=(C 0 -C X ) / C 0 , Where R is the removal rate, C 0 Is the initial concentration of norfloxacin in the solution, C X It is the concentration of norfloxacin in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com