Method for separating and purifying ursolic acid from rosemary

A technology of separation and purification, ursolic acid, applied in the direction of organic chemistry, steroids, etc., to achieve the effect of short time-consuming, low cost, simple and safe method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

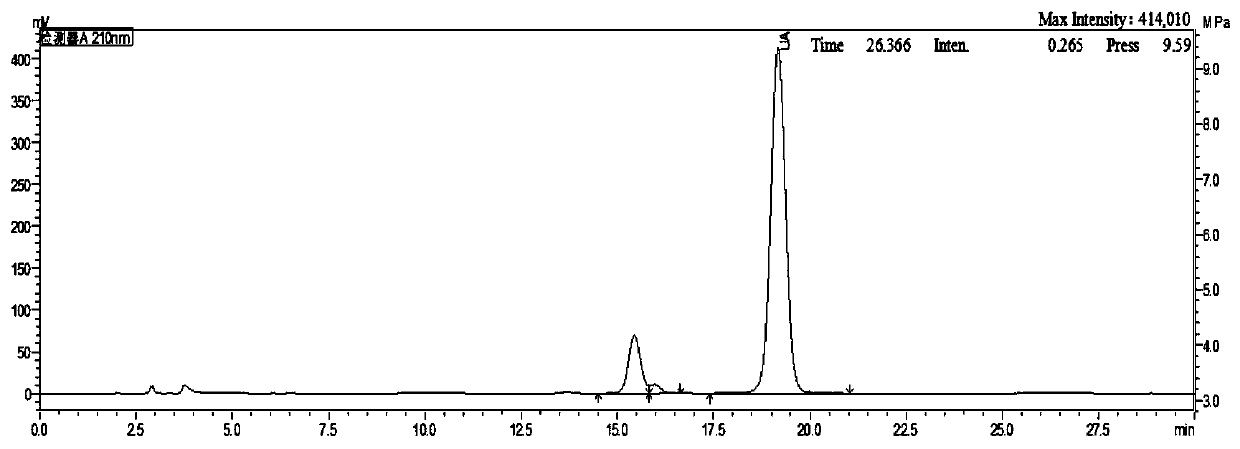

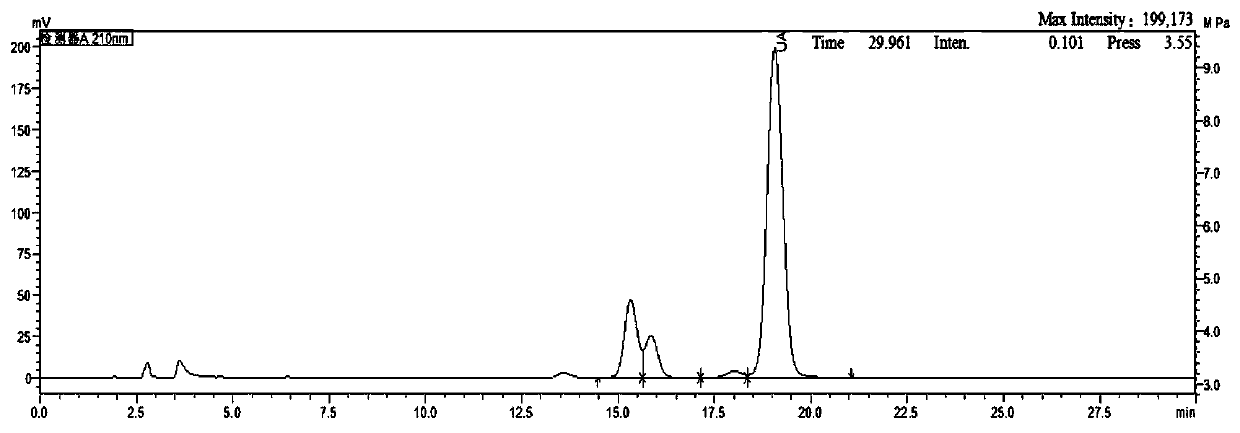

Image

Examples

experiment example 1

[0028] A method for isolating and purifying ursolic acid from rosemary, the steps comprising:

[0029] 1) Take 200g of dried rosemary leaves, heat and reflux them with 1000ml 85% ethanol-water solution twice, extract 1.5h each time, filter to get 1900ml filtrate ①; concentrate the filtrate ① under reduced pressure to 150ml, add 600ml water, place Cool; filter to obtain 60g of filter cake ①, and stir the filter cake ① with 300ml of 3% acetic acid-50% ethanol-water solution for 1h;

[0030] 2) Filtrate to obtain 50g filter cake ②, filter cake ② reflux extraction with 400ml 3% sodium bicarbonate-80% ethanol aqueous solution for 1.5h; filter to obtain 400ml filtrate ②, add 1.2g activated carbon to the filtrate ② for decolorization for 30min;

[0031] 3) filter to get 400ml filtrate 3., add 3% phosphoric acid-water solution to filtrate 3. until precipitate no longer occurs, suction filter to get filter cake 3., filter cake 3. carry out crystallization treatment with ethanol-water s...

experiment example 2

[0033] A method for preparing ursolic acid from rosemary, the steps comprising:

[0034] 1) Take 200g of dried rosemary leaves, heat and reflux them with 1200ml 90% ethanol-water solution for 2 extractions, extract for 1 hour each time, and filter to obtain 2200ml filtrate①; Concentrate the filtrate① under reduced pressure to 140ml, add 420ml of water, place to cool Filter to get 68g filter cake ①, filter cake ① is stirred 50min with 800ml 2% citric acid-80% ethanol-water solution;

[0035] 2) Filter to obtain 60g filter cake ②, filter cake ② was extracted with 540ml 5% sodium carbonate-90% ethanol-water solution for 50min under reflux; filter to obtain 540ml filtrate ②, filtrate ② was decolorized with 1g activated carbon for 40min;

[0036] 3) filter to get 540ml filtrate ③, add 3% acetic acid-water solution to the filtrate until no precipitate occurs, suction filter to get filter cake ③, filter cake ③ is crystallized with ethanol-water solution again, the crystallization con...

experiment example 3

[0038] A method for preparing ursolic acid from rosemary, the steps comprising:

[0039]1) Take 200 g of dried rosemary leaves, heat and reflux them with 1600 ml of 80% ethanol aqueous solution for 3 times, extract for 1 hour each time, and filter to obtain 4600 ml of filtrate ①; concentrate the filtrate ① to 320 ml under reduced pressure, add 760 ml of water, and let it cool; Filter to get 50g filter cake ①, and stir the filter cake ① with 500ml 2% acetic acid-60% ethanol-water solution for 1h;

[0040] 2) Filter to obtain 60g of filter cake ②, filter cake ② with 600ml 2% sodium hydroxide-90% ethanol-water solution for reflux extraction for 1h; filter to obtain 600ml of filtrate ②, filtrate ② plus 3g of activated carbon for decolorization for 30min;

[0041] 3) filter to get 600ml filtrate ③, add 3% hydrochloric acid-water solution to the filtrate until the precipitate no longer occurs, and suction filter to get the filter cake ③, and the filter cake ③ is crystallized with et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com