Experimental system and method for ultra-high temperature corrosion of structural materials under severe nuclear reactor accidents

A serious accident, nuclear reactor technology, applied in the analysis of materials, weather resistance/light resistance/corrosion resistance, material analysis by electromagnetic means, etc., can solve difficult operation, hinder the understanding of the mechanism of serious accident phenomena, and cannot visually observe the material deformation oxide layer Falling off, melting and other problems, to achieve the effect of reducing thermal stress, ensuring mechanical strength and thermal insulation performance, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

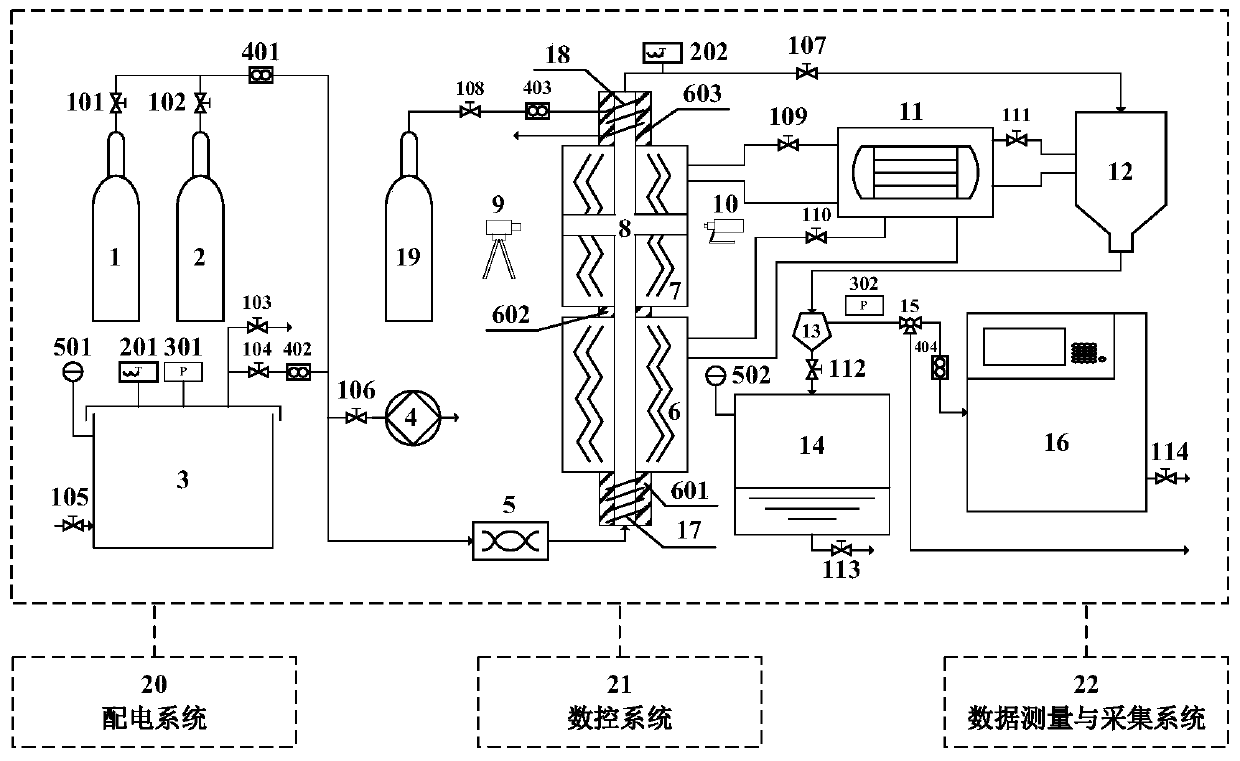

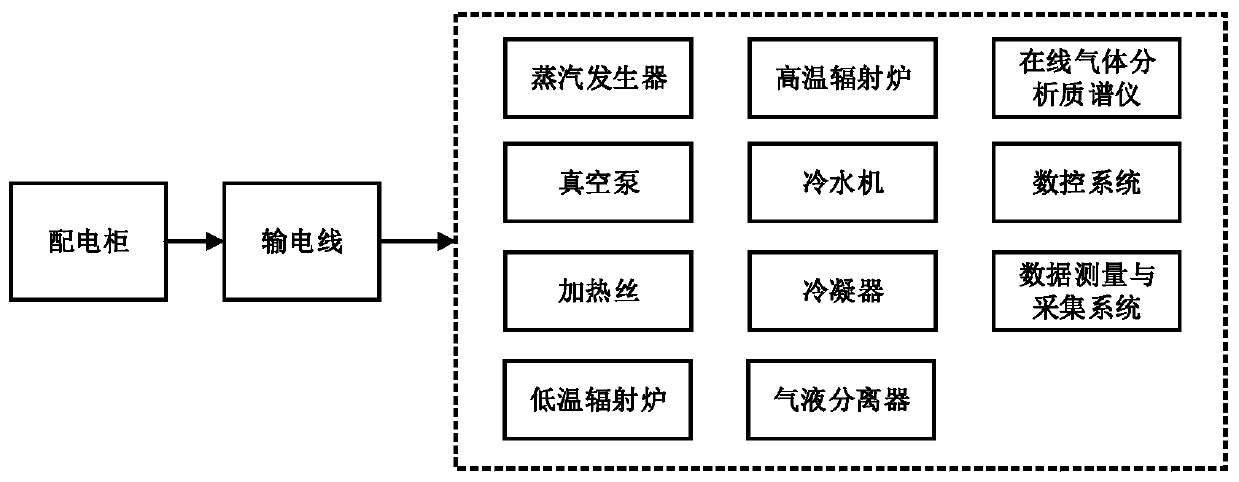

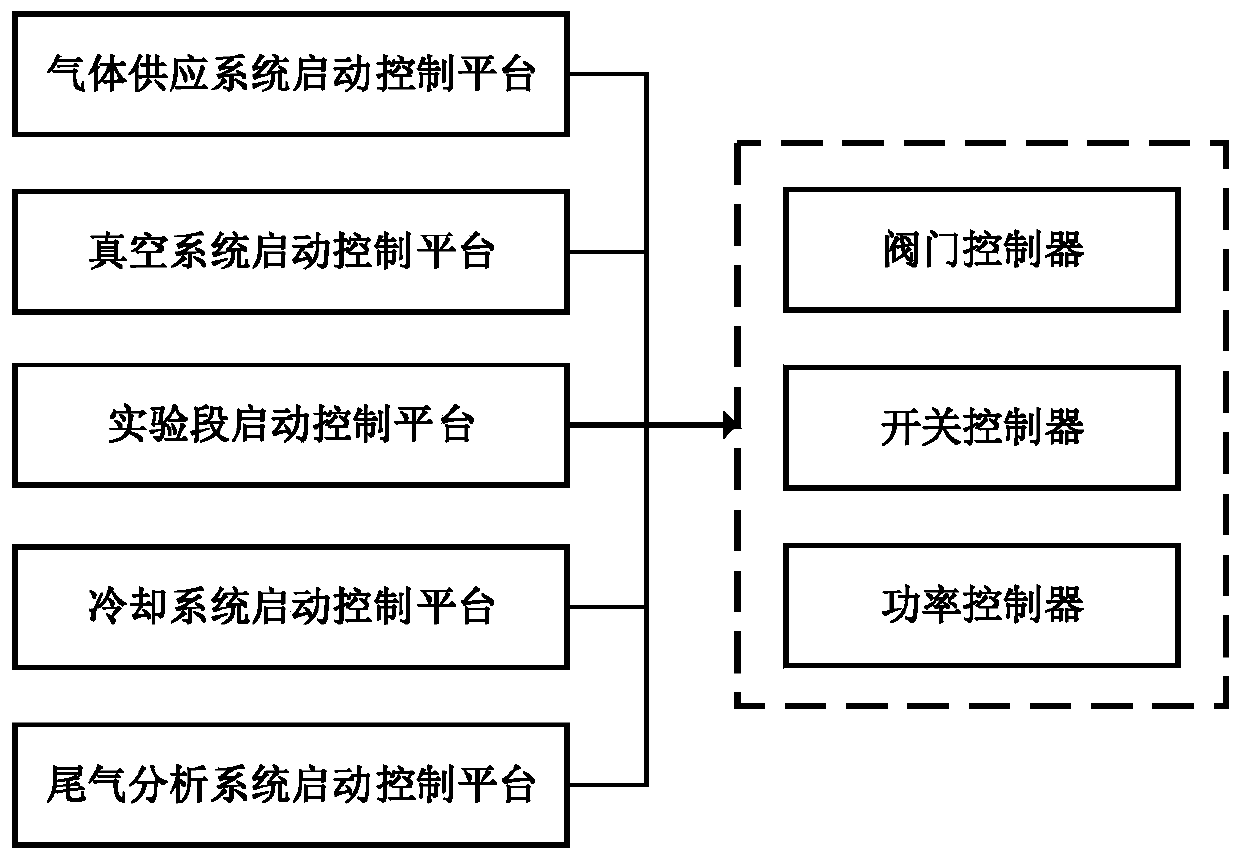

[0027] Such as figure 1 As shown, the present invention is an ultra-high temperature corrosion experimental system and method for structural materials under a severe nuclear reactor accident. The experimental system includes a gas supply system, a vacuum system, an experimental section, a cooling system, and an exhaust gas analysis system, and also includes a supporting power distribution system 20 , a numerical control system 21 and a data measurement and acquisition system 22; the gas supply system includes an argon supply system and a steam supply system; connected, the second argon cylinder 2 is connected with the argon main pipeline through the second valve 102 and corresponding pipelines, the first flow meter 401 is installed on the argon main pipeline, and is used to measure the argon flow of the argon main pipeline, and the second argon The fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com