Polarization-independent double-ridge indium-phosphorus-based optical mixer and preparation method thereof

An optical mixer, indium phosphorus-based technology, applied in the field of coherent optical communication, can solve the problems of imaging blur, mixer performance detection and increased complexity of working mode, affecting the phase accuracy of the mixer, etc., to avoid coupling Alignment, ease of fabrication and integration, time and cost savings in fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

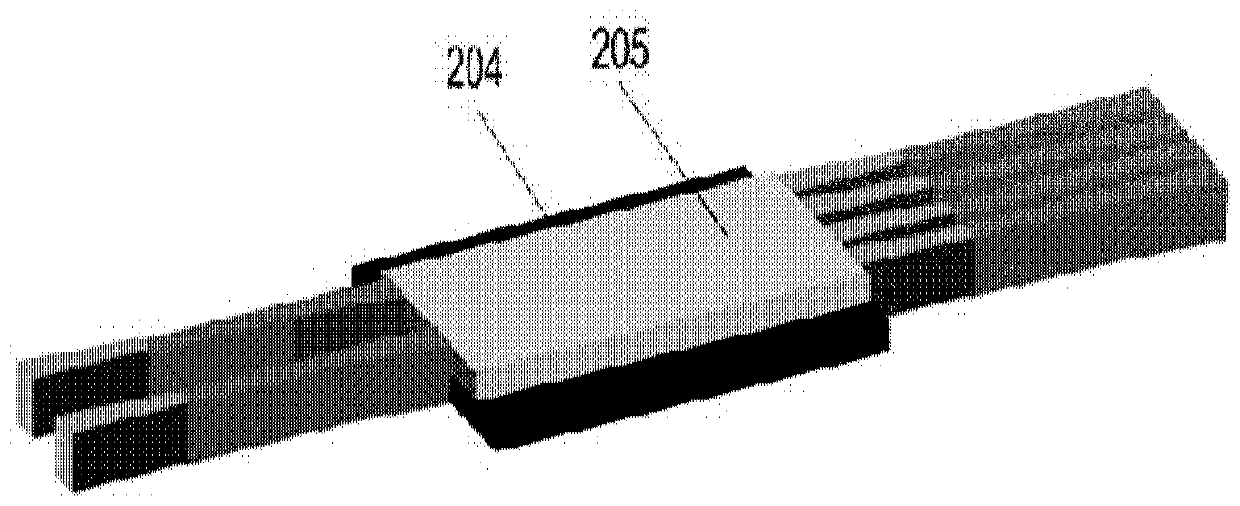

[0087] The present invention also provides a method for preparing a polarization-independent double-ridge indium-phosphorus-based optical mixer, comprising the following steps:

[0088] Prepare epitaxial wafer device layer on indium phosphide substrate;

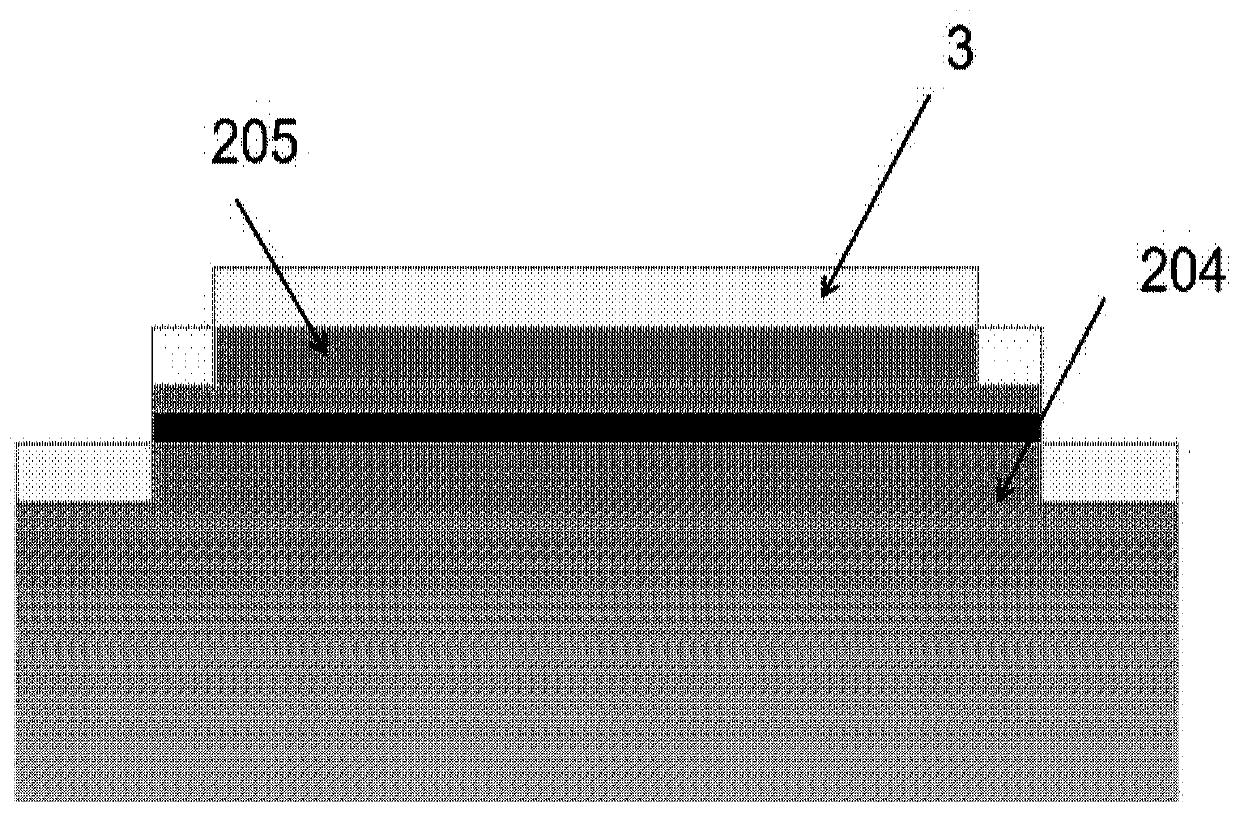

[0089] forming a silicon dioxide upper cladding layer over the epitaxial wafer device layer;

[0090] Antireflection films are formed on both end faces of the optical waveguide.

[0091] Wherein, the preparation of the epitaxial wafer device layer on the indium phosphide substrate specifically includes:

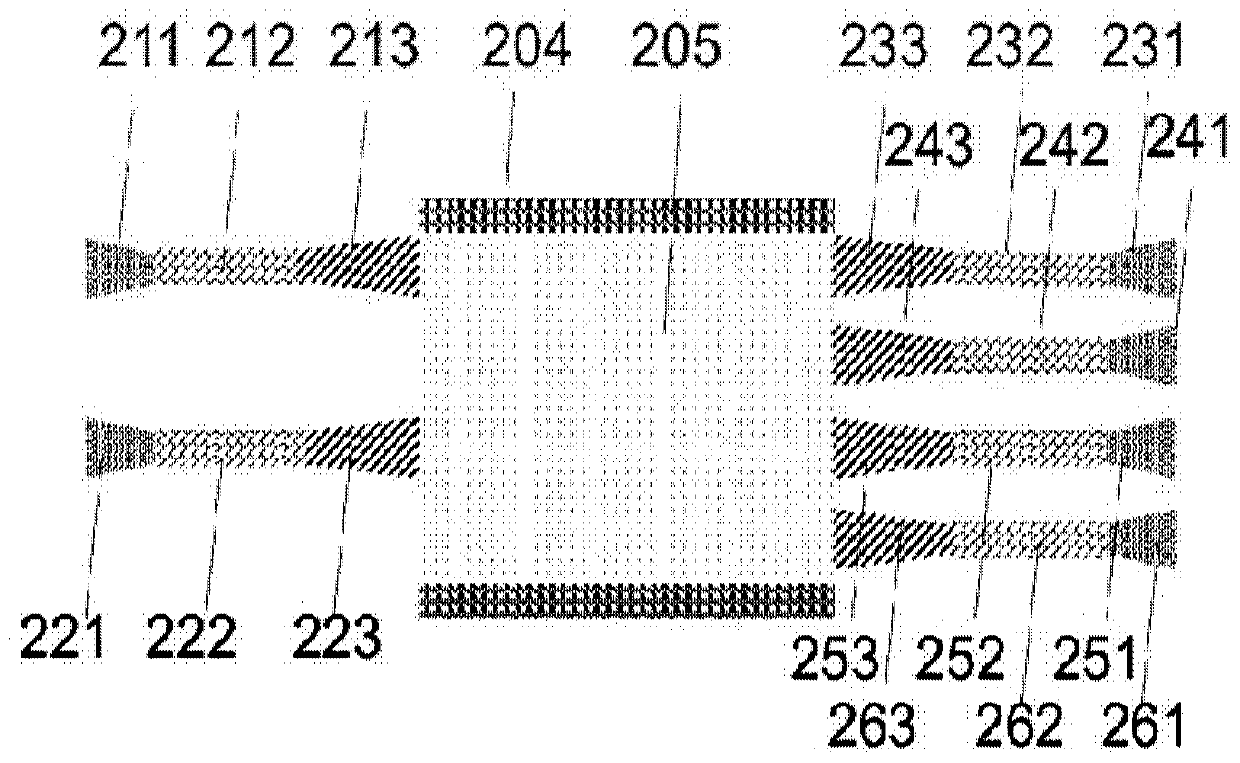

[0092] On the indium phosphorus substrate, an epitaxial wafer device layer is prepared by step-by-step photolithography, step-by-step etching and coating process; among them, the input mode spot converter, the input single-mode straight waveguide, the input width gradient waveguide, and the output mode spot The converter, the output single-mode straight waveguide, and the output width gradient waveguide are all deeply etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com