Lithium ion battery diaphragm and lithium ion battery containing same

A technology for lithium ion batteries and separators, applied in the directions of separators/films/diaphragms/spacers, secondary batteries, battery pack components, etc. Large swelling degree and other problems, to achieve the effect of reducing battery polarization, improving safety risks, and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

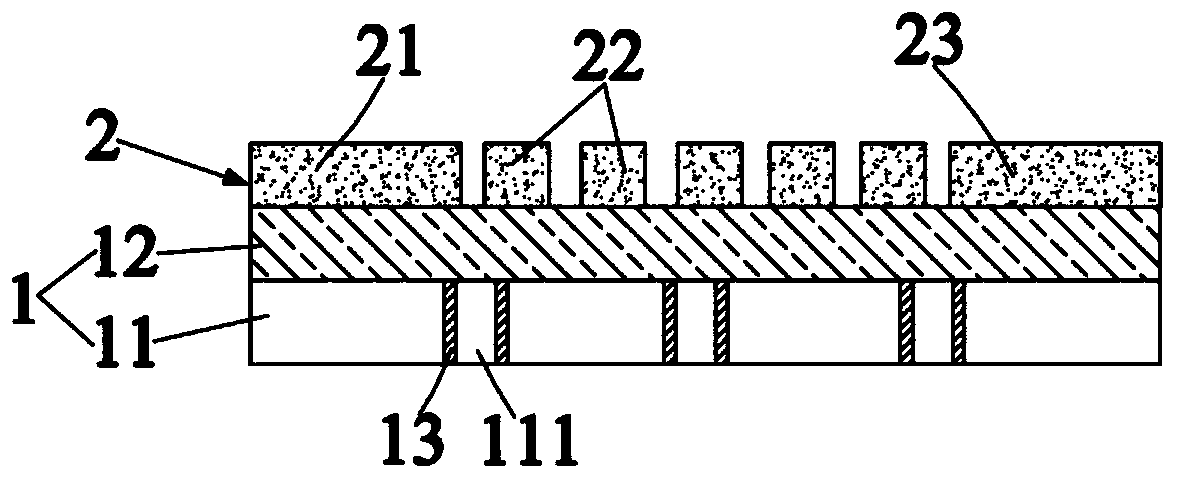

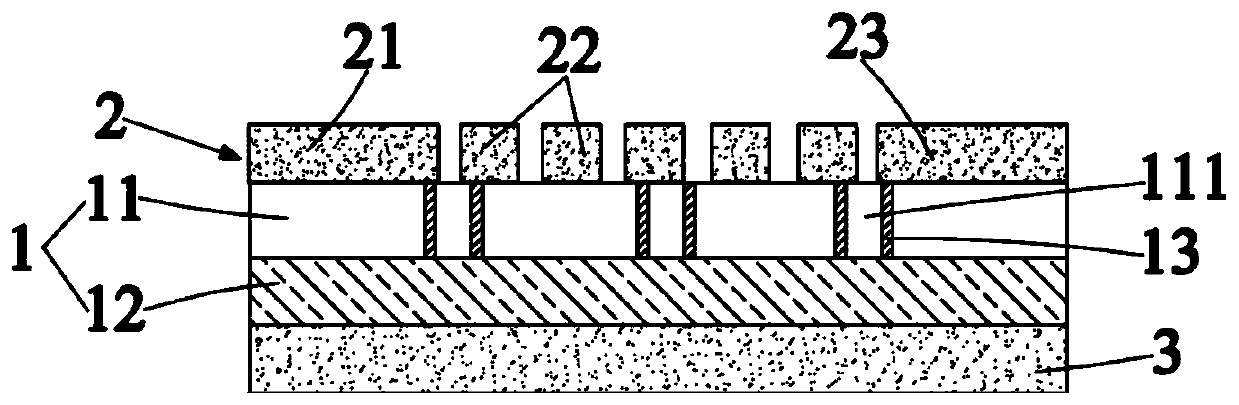

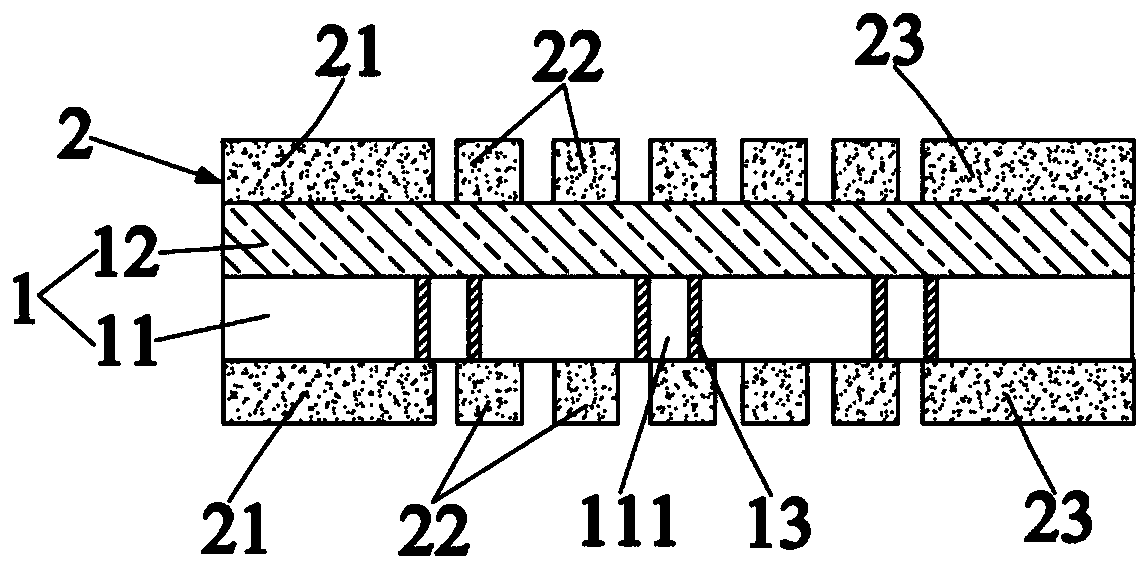

Image

Examples

Embodiment 1

[0038] Preparation of positive electrode sheet:

[0039] Lithium cobaltate, conductive agent superconducting carbon (Super-P), and binder polyvinylidene fluoride (PVDF) were mixed uniformly at a mass ratio of 97:1.5:1.5 to make a lithium-ion battery cathode slurry with a certain viscosity. The slurry is coated on the aluminum foil of the current collector, and then cold pressed after drying at 85°C; then edge trimming, cutting, and slitting are performed, and after slitting, dry at 110°C for 4 hours under vacuum conditions, and weld the tabs. Made into lithium-ion battery cathode sheet.

[0040] Preparation of negative electrode sheet:

[0041] Make a slurry of graphite and conductive agent superconducting carbon (Super-P), thickener sodium carboxymethyl cellulose (CMC), and binder styrene-butadiene rubber (SBR) at a mass ratio of 96:2.0:1.0:1.0 , coated on the current collector copper foil and dried at 85°C, trimmed, cut into pieces, slitting, and dried at 110°C for 4 hours...

Embodiment 2

[0051] Different from Example 1 is the preparation of diaphragm:

[0052] 1) Take a polyethylene microporous membrane with a thickness of 12 μm, a porosity of 45%, and a pore diameter of 90 nm as the base membrane;

[0053] 2) attaching an acrylic modified polyolefin coating with a thickness of 15nm in the pores of the base film by dip coating;

[0054] 3) Coating a ceramic layer on the surface of the base film by gravure roll coating to obtain a heat-resistant composite substrate layer;

[0055] 4) Coating one side of the heat-resistant composite substrate layer with a thickness of 0.5 μm and an area density of 1.2 g / m by gravure roller coating 2 The first organic glue coating; The polymer contained in the first organic glue coating is polymethyl methacrylate with swelling degree less than 300%; The first organic glue coating is sequentially from the upper edge to the lower edge of the base film Including the first complete coating area, the lattice intermittent coating are...

Embodiment 3

[0059] Different from Example 1 is the preparation of diaphragm:

[0060] 1) Take a polyethylene microporous membrane with a thickness of 12 μm, a porosity of 45%, and a pore diameter of 90 nm as the base membrane;

[0061] 2) attaching an acrylic modified polyolefin coating with a thickness of 15nm in the pores of the base film by dip coating;

[0062] 3) Coating a ceramic layer on the surface of the base film by gravure roll coating to obtain a heat-resistant composite substrate layer;

[0063] 4) Coating one side of the heat-resistant composite substrate layer with a thickness of 0.5 μm and an area density of 1.2 g / m by gravure roller coating 2 The first organic glue coating; The polymer contained in the first organic glue coating is polymethyl methacrylate with swelling degree less than 300%; The first organic glue coating is sequentially from the upper edge to the lower edge of the base film Including the first complete coating area, the lattice intermittent coating are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com