Preparation method and uses of MoS2/BiVO4 heterojunction composite photocatalyst

A composite light and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of poor separation of electron holes, small active specific surface area, electrical The problem of slow carrier migration rate, etc., achieves the effect of large active specific surface area, low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

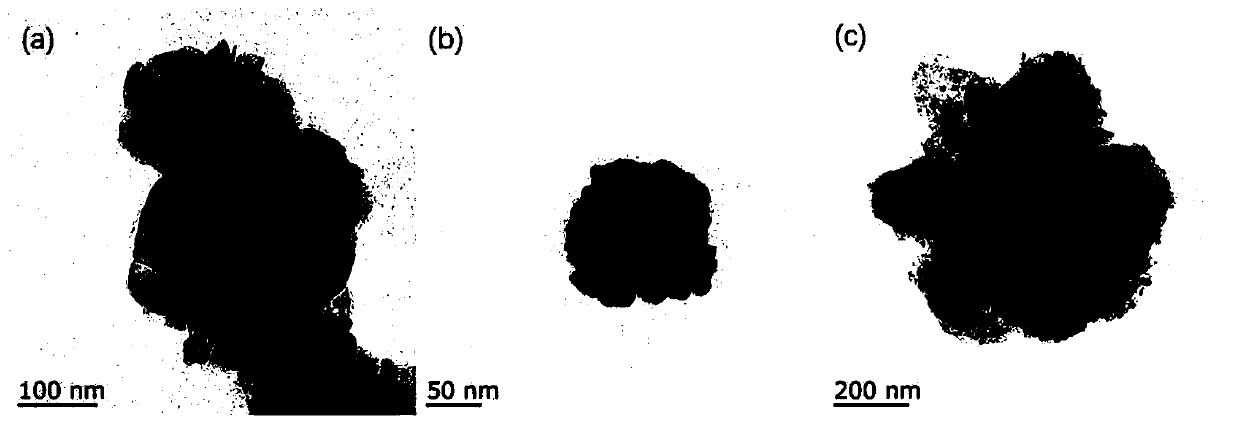

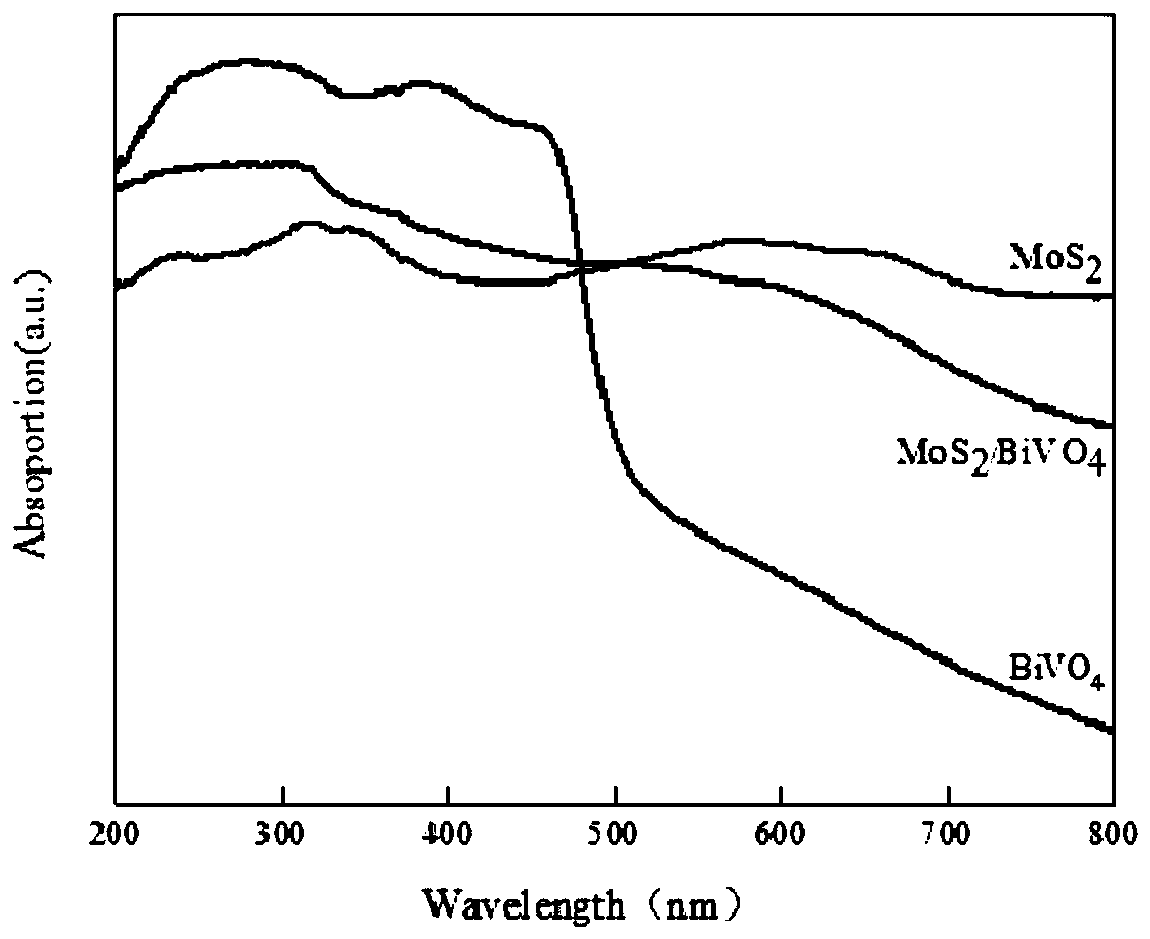

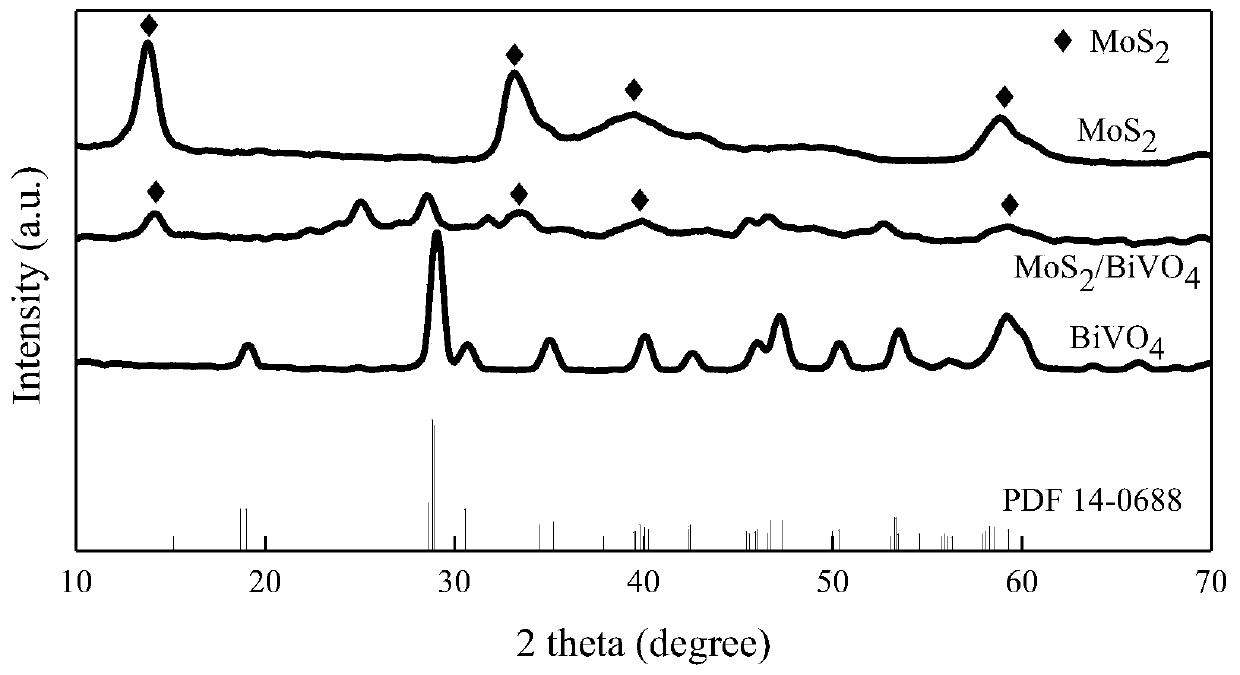

Image

Examples

Embodiment 1

[0033] (1)MoS 2 Preparation of nanosheets: 0.1mmol (NH 4 ) 6 Mo 7 o 24 ﹒ 4H 2 O and 3 mmol CH 4 N 2 Dissolve S in 70mL water, stir vigorously for 30min to form a uniform solution; then, transfer the solution to a Teflon-lined stainless steel autoclave for 230°C, 22h constant temperature thermal reaction; , washing the solid product with ethanol, drying, and then grinding the dried product into a fine powder; 80 mg bulk MoS 2 The powder was dispersed in 400mL water and ethanol mixture, the volume ratio of water and ethanol was 3:1; then ultrasonic vibration and stirring treatment was performed for 8h, and then the suspension was placed in an ultrasonic cleaner and treated for another 20min to precipitate aggregated sheets , and then washed and dried to obtain MoS 2 Nanosheets;

[0034] (2)MoS 2 / BiVO 4 Preparation of composite photocatalyst: 0.0940g Bi(NO) 3 ﹒ 5H 2 O and 0.4g of polyvinylpyrrolidone (PVP; MW ~ 40K) were dissolved in 50mL of ethylene glycol in ult...

Embodiment 2

[0037] (1)MoS 2 Preparation of nanosheets: 0.1mmol (NH 4 ) 6 Mo 7 o 24 ﹒ 4H 2 O and 3 mmol CH 4 N 2 Dissolve S in 70mL water and stir vigorously for 30min to form a uniform solution; then, transfer the solution to a Teflon-lined stainless steel autoclave for 220°C, 24h constant temperature thermal reaction; , washing the solid product with ethanol, drying, and then grinding the dried product into a fine powder; 80 mg of MoS 2 The powder was dispersed in 400mL water and ethanol mixture, the volume ratio of water and ethanol was 3:1; then ultrasonic vibration and stirring treatment was performed for 8h, and then the suspension was placed in an ultrasonic cleaner and treated for another 30min to precipitate aggregated sheets , and then washed and dried to obtain MoS 2 Nanosheets;

[0038] (2)MoS 2 / BiVO 4 Preparation of composite photocatalyst: 0.105g Bi(NO) 3 ﹒ 5H 2 O and 0.4 g of polyvinylpyrrolidone (PVP; MW ~ 40K) were dissolved in 50 mL of ethylene glycol in u...

Embodiment 3

[0041] (1)MoS 2 Preparation of nanosheets: 0.1mmol (NH 4 ) 6 Mo 7 o 24 ﹒ 4H 2 O and 3 mmol CH 4 N 2 Dissolve S in 70mL water, stir vigorously for 30min to form a uniform solution; then, transfer the solution to a Teflon-lined stainless steel autoclave for 240°C, 22h constant temperature thermal reaction; , washing the solid product with ethanol, drying, and then grinding the dried product into a fine powder; 80 mg of MoS 2 The powder was dispersed in 400mL water and ethanol mixture, the volume ratio of water and ethanol was 3:1; then ultrasonic vibration and stirring treatment was performed for 10h, and then the suspension was placed in an ultrasonic cleaner and treated for another 30min to precipitate aggregated sheets , and then washed and dried to obtain MoS 2 Nanosheets;

[0042] (2)MoS 2 / BiVO 4 Preparation of composite photocatalyst: 0.102g Bi(NO) 3 ﹒ 5H 2 O and 0.4 g of polyvinylpyrrolidone (PVP; MW ~ 40K) were dissolved in 50 mL of ethylene glycol and ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com