Intelligent sorting method for lead-zinc massive ore

An ore and intelligent technology, which is applied in the field of intelligent separation of lead-zinc block ore, can solve the problems of unspecified lead-zinc block ore separation method and complicated operation, so as to improve the selected grade and processing capacity of the concentrator, and alleviate Insufficient storage capacity and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

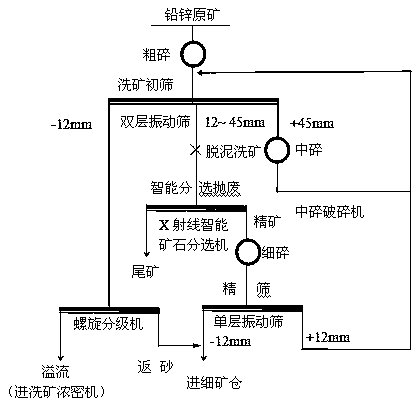

[0031] refer to figure 1 , a kind of lead-zinc massive ore intelligent sorting method of this implementation, carry out according to the following steps:

[0032] (1) Coarse crushing and primary screening: The lead-zinc raw ore is crushed by a primary crusher and then passed through a double-layer vibrating screen for washing, screening and grading to obtain three particle size grades of +45mm, +12mm ~ -45mm, -12mm ore;

[0033] (2) Secondary crushing: The +45mm ore screened out in step 1) is transported by belt to the secondary crushing crusher, and the crushed ore is transported back to the double-layer vibrating screen in step 1) by belt for washing screen Minute;

[0034] (3) Intelligent sorting and discarding: the +12mm ~ -45mm ore initially screened in step 1) is transported to the X-ray intelligent ore sorting machine through the transport belt for intelligent sorting and discarding, and the X-ray intelligent ore is sorted In the control system of the machine, the se...

Embodiment 2

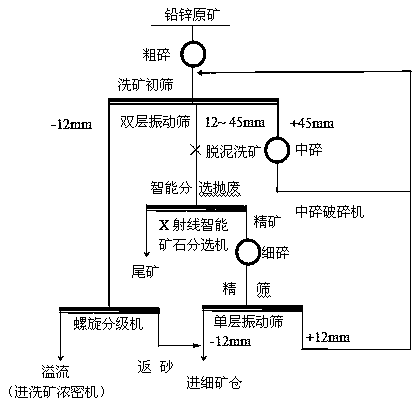

[0040] refer to figure 2 , a kind of lead-zinc massive ore intelligent sorting method of this implementation, carry out according to the following steps:

[0041] (1) Coarse crushing and primary screening: The raw lead-zinc ore is crushed by a primary crusher and then passed through a double-layer vibrating screen for washing, screening and grading to obtain three particle sizes of +50mm, +10 mm ~ -50mm, -10 mm grade of ore;

[0042] (2) Secondary crushing: The +50mm ore screened out in step 1) is transported by belt to the secondary crushing crusher, and the crushed ore is transported back to the double-layer vibrating screen in step 1) by belt for washing screen Minute;

[0043] (3) Intelligent sorting and discarding: the +10 mm ~ -50mm ore initially screened in step 1) is transported to the X-ray intelligent ore sorting machine through the conveyor belt for intelligent sorting and discarding. In the control system of the concentrator, the separation threshold of concent...

Embodiment 3

[0049] A kind of lead-zinc massive ore intelligent sorting method of this implementation, carry out according to the following steps:

[0050] (1) Coarse crushing and primary screening: The raw lead-zinc ore is crushed by a primary crusher and then passed through a double-layer vibrating screen for washing, screening and grading to obtain three particle sizes of +50mm, +10 mm ~ -50mm, -10 mm grade of ore;

[0051] (2) Secondary crushing: The +50mm ore screened out in step 1) is transported by belt to the secondary crushing crusher, and the crushed ore is transported back to the double-layer vibrating screen in step 1) by belt for washing screen Minute;

[0052] (3) Intelligent sorting and discarding: the +10 mm ~ -50mm ore initially screened in step 1) is transported to the X-ray intelligent ore sorting machine through the conveyor belt for intelligent sorting and discarding. In the control system of the concentrator, the threshold for separation of concentrate and tailings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com