Method and device for harmless treatment of recycled copper oxychloride

A technology of harmless treatment and copper chloride, applied in the direction of copper chloride, copper halide, etc., to achieve the effect of simple process flow, large processing capacity and maximization of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

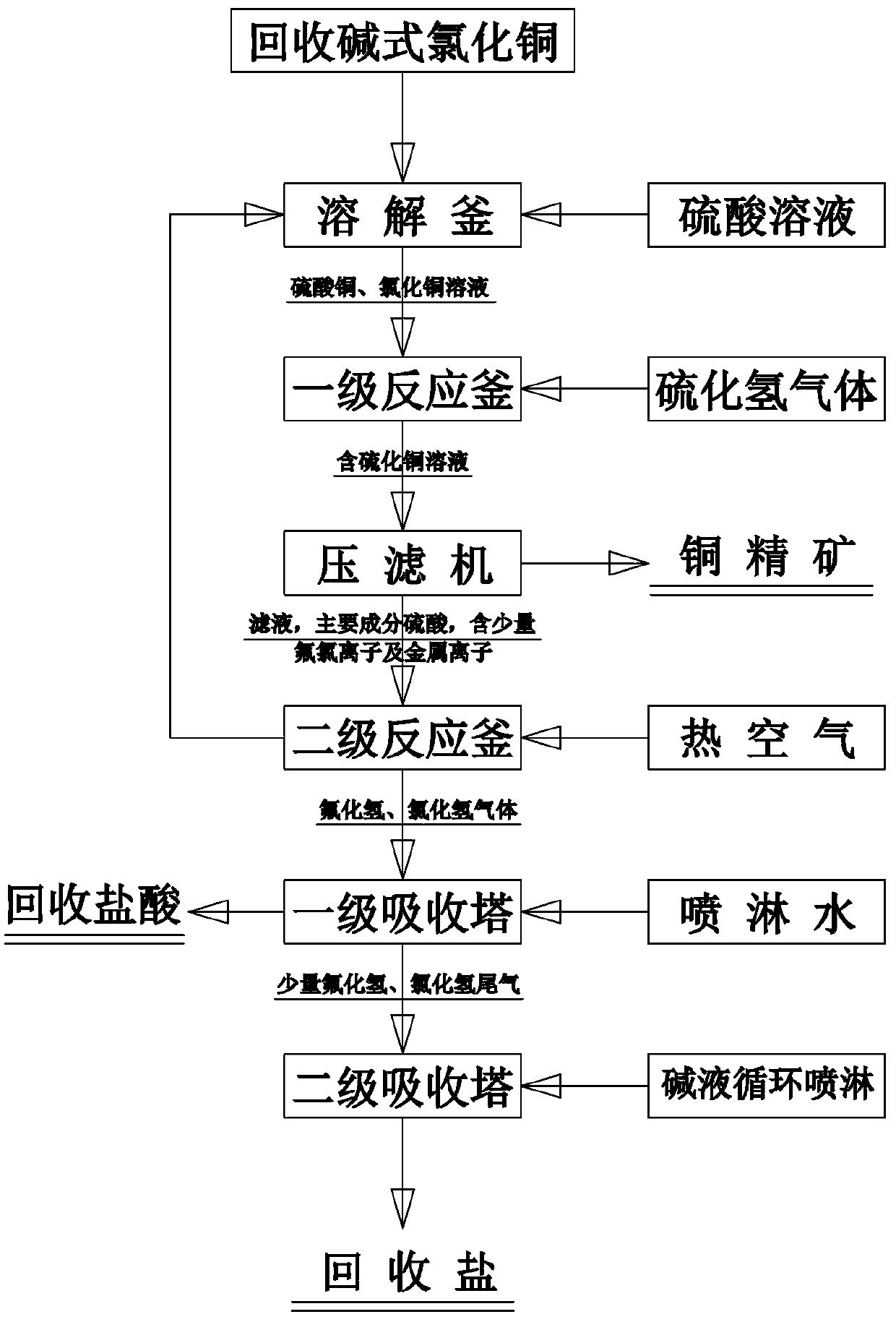

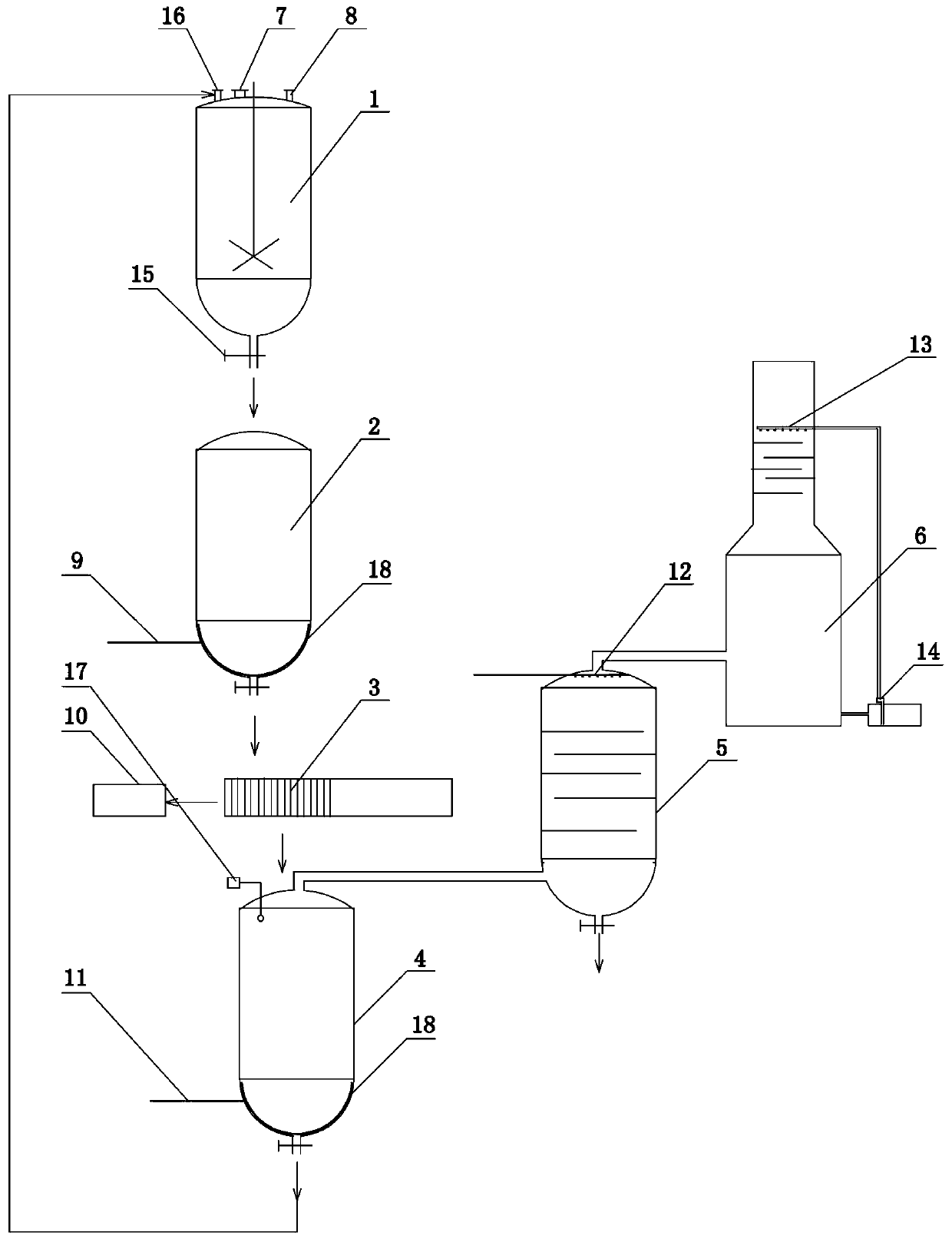

[0053] see figure 1 , a method for harmless treatment and recovery of basic copper chloride, comprising the steps of:

[0054] (1) Add the recovered basic copper chloride into the dissolution kettle 1 with a stirring device, slowly add a sulfuric acid solution with a mass fraction of 40%, stir while adding, until the pH of the feed liquid is stable to 7.5, and detect the copper ions in the feed liquid The content is 42g / L, and the total volume of feed liquid is 35m 3 ;

[0055] (2) Transfer the feed liquid to the primary reactor 2, fill the feed liquid with 3 / 4 volume of the primary reactor, seal the top of the primary reactor, and slowly inject hydrogen sulfide gas into the primary reactor from the bottom of the reactor , control the flow rate of hydrogen sulfide gas to 0.8m 3 / min, the amount of feed is 0.5 times the molar amount of copper ions (253L), after the completion of hydrogen sulfide feed, keep the sealed state for 15 minutes;

[0056] (3) Release the material f...

Embodiment 2

[0060] A method for harmless treatment and recovery of basic copper chloride, comprising the steps of:

[0061] (1) Add the recovered basic copper chloride into a dissolution kettle with a stirring device, slowly add a sulfuric acid solution with a mass fraction of 20%, and stir while adding until the pH of the feed liquid is stable to 7.0, and detect the copper ion content in the feed liquid 30g / L, the total volume of feed liquid is 30m 3 ;

[0062] (2) Transfer the feed liquid to the primary reactor, make the feed liquid fill 2 / 3 of the volume of the primary reactor, seal the top of the primary reactor, and slowly introduce hydrogen sulfide gas from the bottom of the reactor into the primary reactor, Control the flow rate of hydrogen sulfide gas to 0.5m 3 / min, the feed rate is 0.7 times the copper ion content (220L), after the hydrogen sulfide feed is completed, keep the sealed state for 10 min;

[0063] (3) Release the material from the bottom of the primary reactor, pr...

Embodiment 3

[0067] see figure 1 , a method for harmless treatment and recovery of basic copper chloride, comprising the steps of:

[0068] (1) Add the recovered basic copper chloride into a dissolution kettle with a stirring device, slowly add a sulfuric acid solution with a mass fraction of 80%, and stir while adding until the pH of the feed liquid is stable to 8, and detect the copper ion content in the feed liquid is 50g / L, and the total volume of feed liquid is 30m 3 ;

[0069] (2) Transfer the feed liquid to the primary reactor, make the feed liquid fill 3 / 4 of the volume of the primary reactor, seal the top of the primary reactor, and slowly inject hydrogen sulfide gas from the bottom of the reactor into the primary reactor, Control the flow rate of hydrogen sulfide gas to 1m 3 / min, the feeding amount is twice the copper ion content (447L), after the hydrogen sulfide feeding is completed, keep the sealed state for 10 minutes;

[0070](3) Release the material from the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com