Oil stain treatment system based on Internet of Things

An Internet of Things technology and treatment system technology, applied in the field of oil pollution treatment, can solve the problems of low oil pollution treatment effect, lack of intelligent and macroscopic management, etc., achieve the effect of saving water and ensuring the effect of cleaning pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

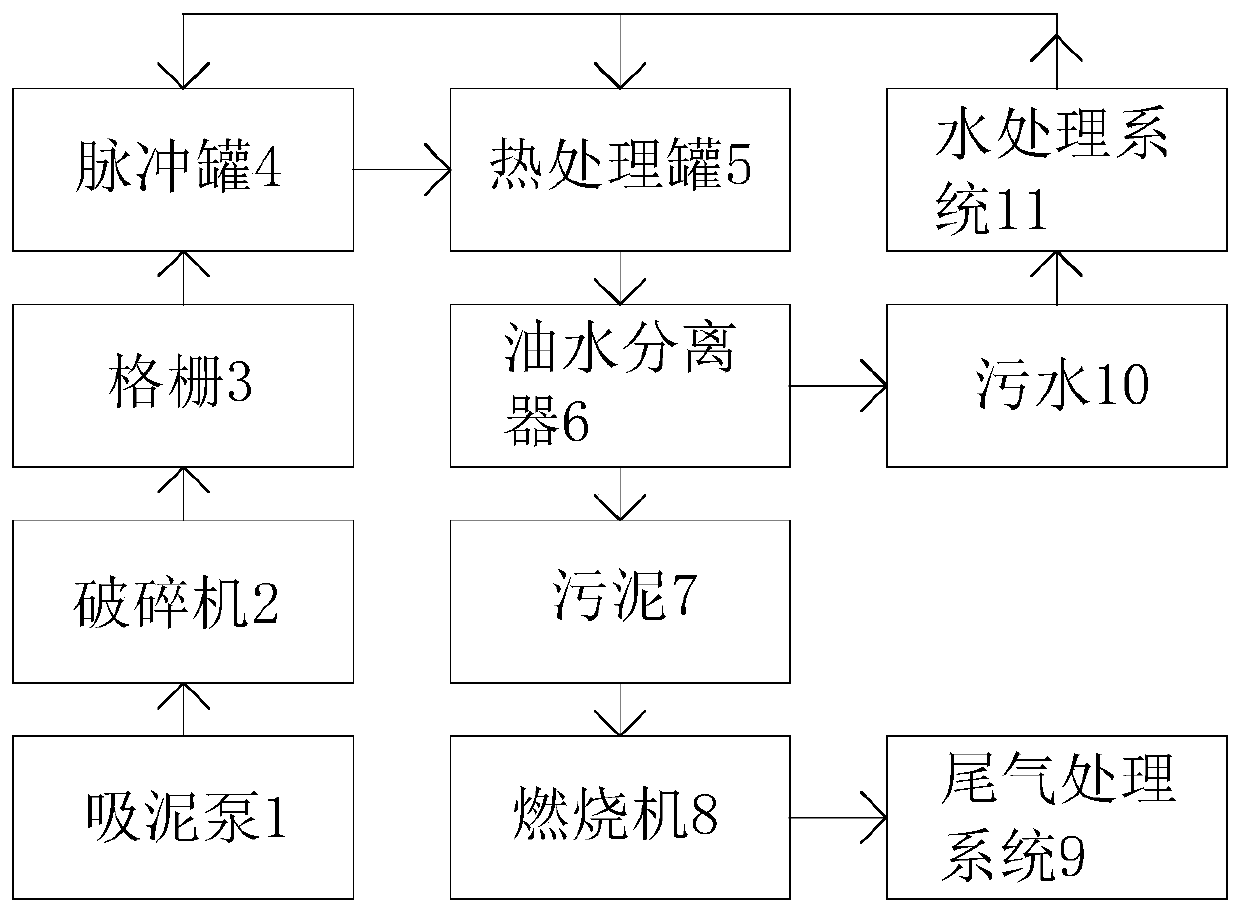

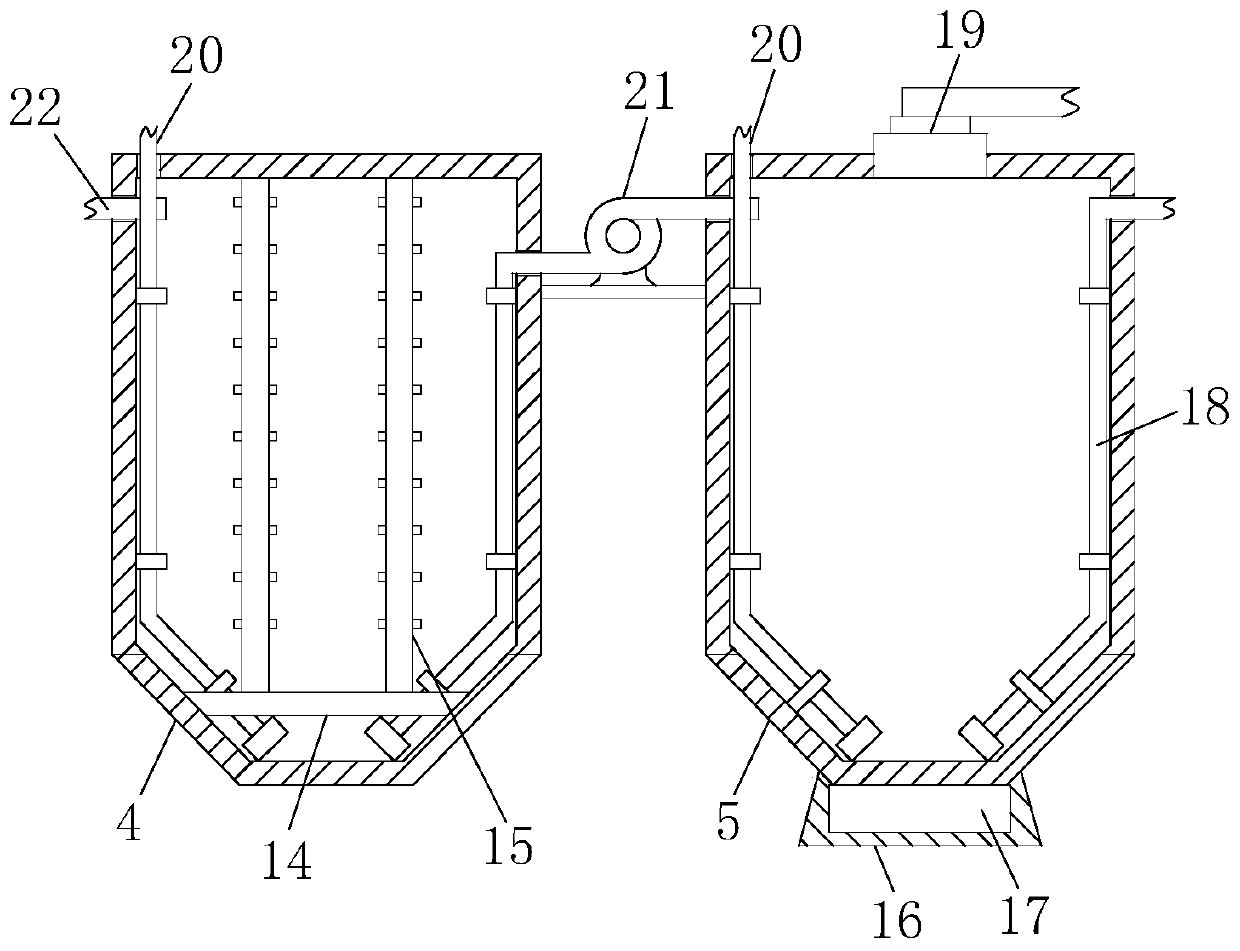

[0026] Example 1, please refer to figure 1 and 3 ~4. An oil pollution treatment system based on the Internet of Things technology, including an oil pollution treatment system and an intelligent monitoring and management system;

[0027] The oil pollution treatment system includes a dredge pump 1, a crusher 2, a grid 3, an impulse tank 4, a heat treatment tank 5, an oil-water separator 6, a burner 8 and an exhaust gas treatment system 9 connected in sequence, and the oil-water separator 6 The separated sludge 7 enters the burner 8, and the separated sewage 10 enters the water treatment system 11. The water treatment system 11 is connected with the pulse tank 4 and the heat treatment tank 5 through the flushing pipe 20. The left side of the pulse tank 4 is installed There is a sewage inlet pipe 22, the heat treatment tank 5 is located on the right side of the pulse tank 4, an extraction pump 21 is arranged between the pulse tank 4 and the heat treatment tank 5, and the two ends...

Embodiment 2

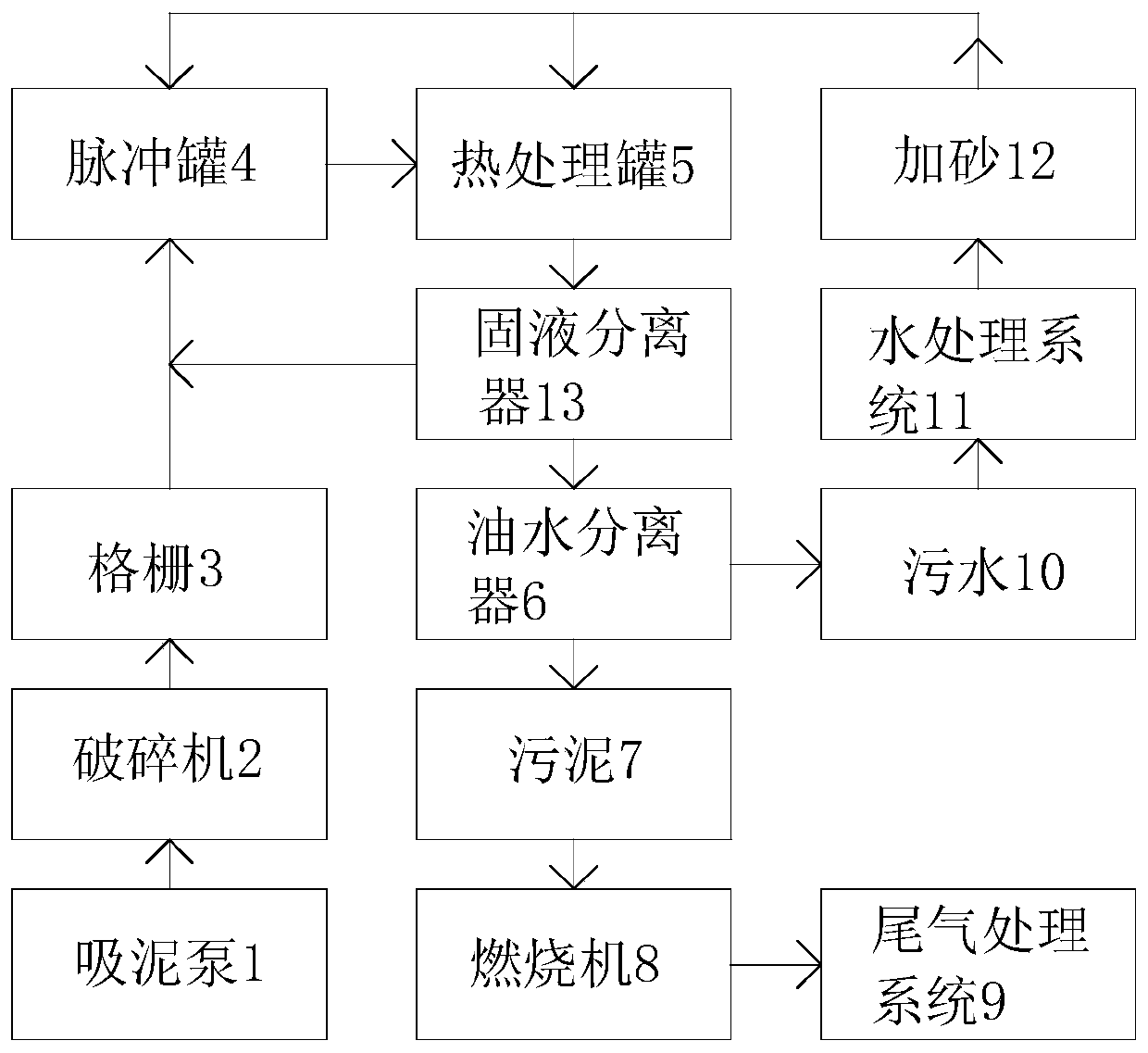

[0029] Example 2, please refer to Figure 2-4 , an oil pollution treatment system based on Internet of Things technology, including an oil pollution treatment system and an intelligent monitoring and management system;

[0030]The oil pollution treatment system includes a dredge pump 1, a crusher 2, a grid 3, an impulse tank 4, a heat treatment tank 5, a solid-liquid separator 13, an oil-water separator 6, a burner 8 and an exhaust gas treatment system 9 connected in sequence, The solid-liquid separator 13 is connected with the pulse tank 4 at the same time, the sludge 7 separated by the oil-water separator 6 enters the burner 8, and the separated sewage 10 enters the water treatment system 11, and the water treatment system 11 passes through the flushing pipe 20 is connected with the pulse tank 4 and the heat treatment tank 5, and a sanding 12 is also provided between the water treatment system 11, the pulse tank 4 and the heat treatment tank 5, and the sewage inlet pipe 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com