A preparation method for recycling waste resin sand to reprocess rubber and plastic filler

A resin molding sand reprocessing technology, applied in the field of molding sand recycling, can solve problems such as failure to achieve 100% recovery, failure to get rid of fine powder, and smoke generated by reclaimed sand recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

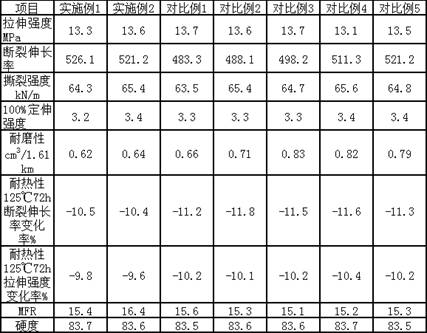

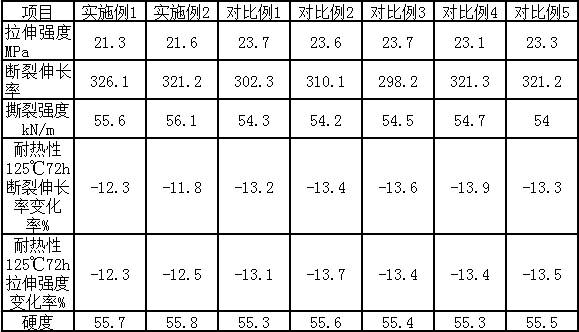

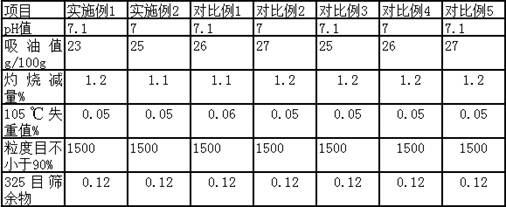

Examples

Embodiment 1

[0020] A preparation method for recycling waste resin molding sand to reprocess rubber and plastic filler, comprising the following steps:

[0021] (1) After aging the resin sand waste at -15°C for xenon lamp and ozone for 30 hours, start the ball mill device and grind it, and then combine it with chloroform solvent, triethylamine, coconut oil fatty acid diethanolamide and alkaline detergent Add the materials together to the reaction kettle, under the action of stirring, sonicate and heat to 30°C in a sealed manner, and then cool down to room temperature after 1 hour of heat preservation, start the ball mill device and grind and pulverize, and pass through a 200-mesh sieve to obtain a powder chloroform dispersion; the microwave heating The power is 300W, the frequency is 60kHz, and the raw materials according to parts by weight are: 140 parts of resin molding sand waste, 83 parts of chloroform solvent, 4.5 parts of triethylamine, 1.2 parts of ethylene glycol, 50 parts of deioni...

Embodiment 2

[0030] A preparation method for recycling waste resin molding sand to reprocess rubber and plastic filler, comprising the following steps:

[0031] (1) After aging the resin sand waste at 10°C for xenon lamp and ozone for 42 hours, start the ball mill device and grind it, and then mix it with chloroform solvent, triethylamine, coconut oil fatty acid diethanolamide and alkaline detergent composition Put them into the reaction kettle together, under the action of stirring, ultrasonically treat and airtightly heat to 30 ° C, keep warm for 2 hours and then drop to room temperature, start the ball mill device and carry out grinding and crushing, and pass through a 200 mesh sieve to obtain a powder chloroform dispersion; the microwave-heated The power is 300W, the frequency is 60kHz, and the raw materials according to parts by weight are: 140 parts of resin molding sand waste, 65 parts of chloroform solvent, 3.5 parts of triethylamine, 0.8 part of ethylene glycol, 30 parts of deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com