Quinine-modified basalt fiber carrier and preparation method and application thereof

A basalt fiber and carrier technology, applied in fiber treatment, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of quinone compound effluent loss and secondary pollution, so as to promote anaerobic biotransformation rate and solve secondary pollution. Contamination, effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

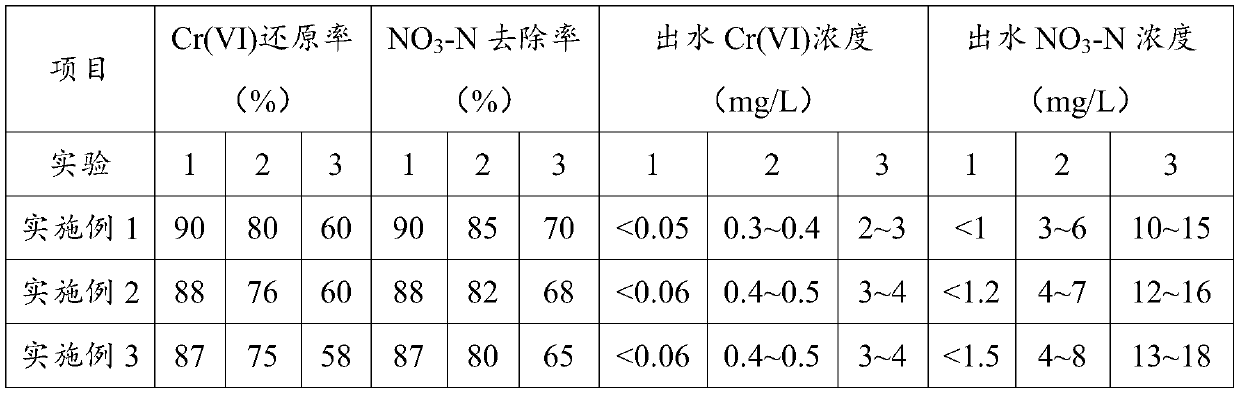

Examples

Embodiment 1

[0026] Pretreatment: first place the basalt fiber in a Soxhlet extractor, extract it with acetone for 12 hours, then soak it in distilled water for 3 times, each time for 30 minutes, to remove surface impurities, then dry it in an oven at 80°C for 3.5 hours, and then Cool in a desiccator; finally place the basalt fiber in H 2 SO 4 / H 2 o 2 (v / v=7:3) in the mixed solution, after reacting at 90°C for 1 hour, washing and drying;

[0027] Amino functionalization: Add 5mg of nano-silica, 20ml of 20% γ-aminopropyltriethoxysilane into a 50ml three-neck flask, stir in a water bath at 45°C for 30min to obtain a mixed solution; mix the mixed solution and pretreatment The basalt fiber is placed in an ultrasonic instrument and ultrasonicated for 1 hour, and dried at 105°C to make nano-silica adhere to the surface of the basalt fiber, and γ-aminopropyltriethoxysilane is condensed on the surface of the basalt fiber to form a coupling agent After the reaction, the basalt fiber was taken ...

Embodiment 2

[0030] Pretreatment: first place the basalt fiber in a Soxhlet extractor, extract it with acetone for 12 hours, then soak it in distilled water for 4 times, 20 minutes each time, to remove surface impurities, then dry it in an oven at 75°C for 4 hours, and then put it in Cool in a desiccator; finally place the basalt fiber in H 2 SO 4 / H 2 o 2 (v / v=7:3) in the mixed solution, after reacting at 80°C for 1 hour, washing and drying;

[0031] Amino functionalization: add 8mg of nano-silica, 25ml of 20% γ-aminopropyltriethoxysilane into a 50ml three-neck flask, stir in a water bath at 40°C for 40min to obtain a mixed solution; mix the mixed solution and pretreatment The basalt fiber is placed in an ultrasonic instrument and ultrasonicated for 1 hour, then dried at 100°C to make nano-silica adhere to the surface of the basalt fiber, and γ-aminopropyltriethoxysilane is condensed on the surface of the basalt fiber to form a coupling agent After the reaction, the basalt fiber was t...

Embodiment 3

[0034] Pretreatment: first place the basalt fiber in a Soxhlet extractor, extract it with acetone for 12 hours, then soak it in distilled water for 5 times, 20 minutes each time, to remove surface impurities, then dry it in an oven at 90°C for 3 hours, and then place it in Cool in a desiccator; finally place the basalt fiber in H 2 SO 4 / H 2 o 2 (v / v=7:3) in the mixed solution, after reacting at 100°C for 1 hour, washing and drying;

[0035] Amino functionalization: add 15mg of nano-silica, 30ml of 20% γ-aminopropyltriethoxysilane into a 50ml three-neck flask, stir in a water bath at 50°C for 20min to obtain a mixed solution; mix the mixed solution and pretreatment The basalt fiber is placed in an ultrasonic instrument and ultrasonicated for 1 hour, then dried at 110°C to make nano-silica adhere to the surface of the basalt fiber, and γ-aminopropyltriethoxysilane is condensed on the surface of the basalt fiber to form a coupling agent After the reaction, the basalt fiber w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com