Coil self-excitation-based ferromagnetic pipeline electromagnetic ultrasonic transducer, excitation device and receiving device

An electromagnetic ultrasonic and ferromagnetic technology, which is applied in measuring devices, ultrasonic/sonic/infrasonic generation, material analysis using sound/ultrasonic/infrasonic, etc. It can solve the problem of large probe volume, low ultrasonic excitation efficiency, and unsuitable for small size. The requirements of modernization and portability, etc., achieve the effect of reducing volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

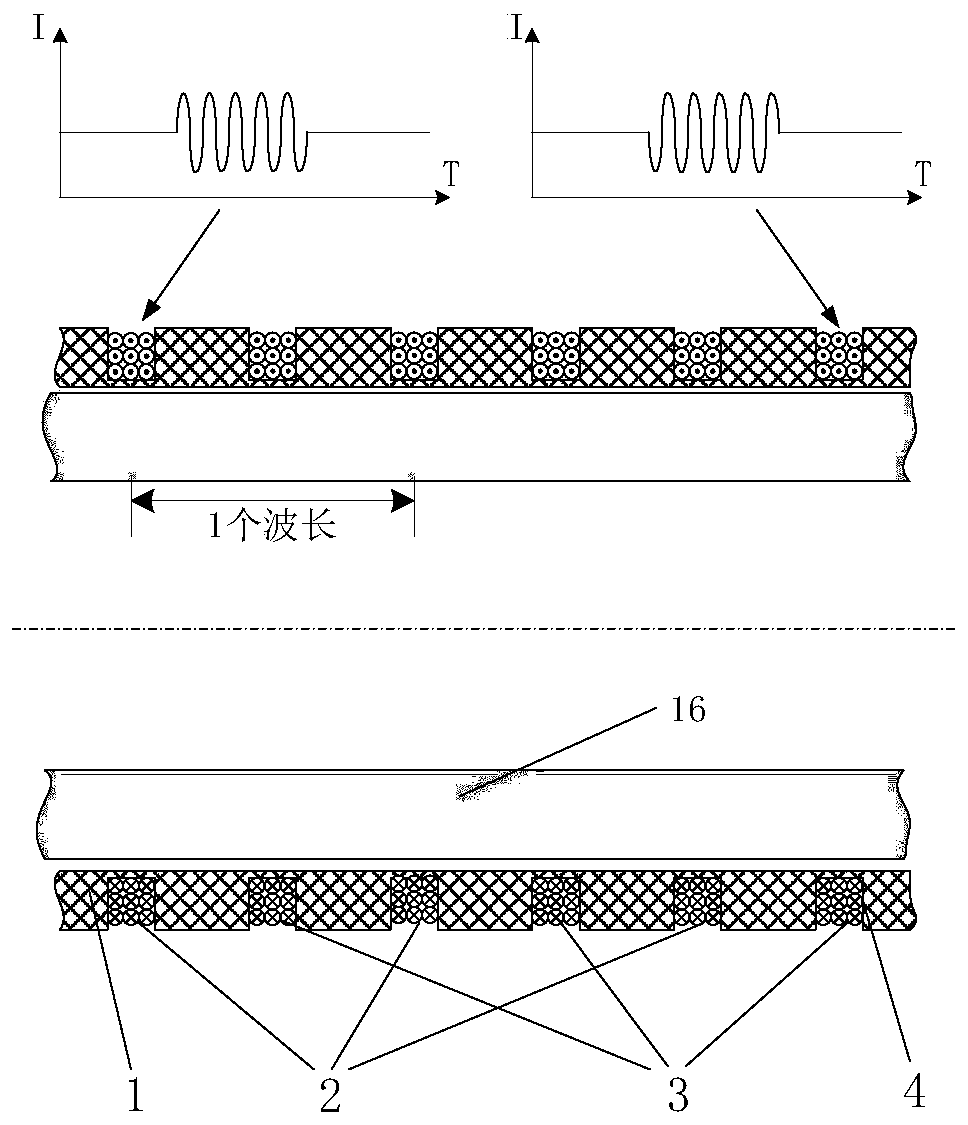

[0042] see figure 1 , which is a structural schematic diagram of Embodiment 1 of the present invention, provides a ferromagnetic tube electromagnetic ultrasonic transducer with coil self-excitation, including: a skeleton 1, a normal-phase coil group 2, and an anti-phase coil group 3, wherein,

[0043] Skeleton 1 is a hollow cylindrical tube of insulating material, its inner diameter is slightly larger than the outer diameter of the ferromagnetic pipeline to be tested, and is coaxially sleeved on the outer surface of the pipeline. On the upper surface of the frame 1, there are 6 annular wire slots 4 at equal intervals; the distance between the wire slots 4 is 5mm, which is 1 / 2 of the wavelength of the excited ultrasonic waves.

[0044] The positive-phase coil group 2 is composed of 3 positive-phase coils connected in series; the normal-phase coil is a ring coil; the number of turns of each positive-phase coil is 9 turns, and the copper enameled wire with a diameter of Ф1 mm is ...

Embodiment 2

[0052] see Figure 5 , which is a structural block diagram of Embodiment 2 of the present invention, provides a coil self-excited ferromagnetic pipeline electromagnetic ultrasonic excitation device, including: electromagnetic ultrasonic transducer 5, high-power constant current source 6, pulse signal source 7, reverse phase Device 8, non-phase power amplifier 9, inverting power amplifier 10, isolation capacitor 11, wherein,

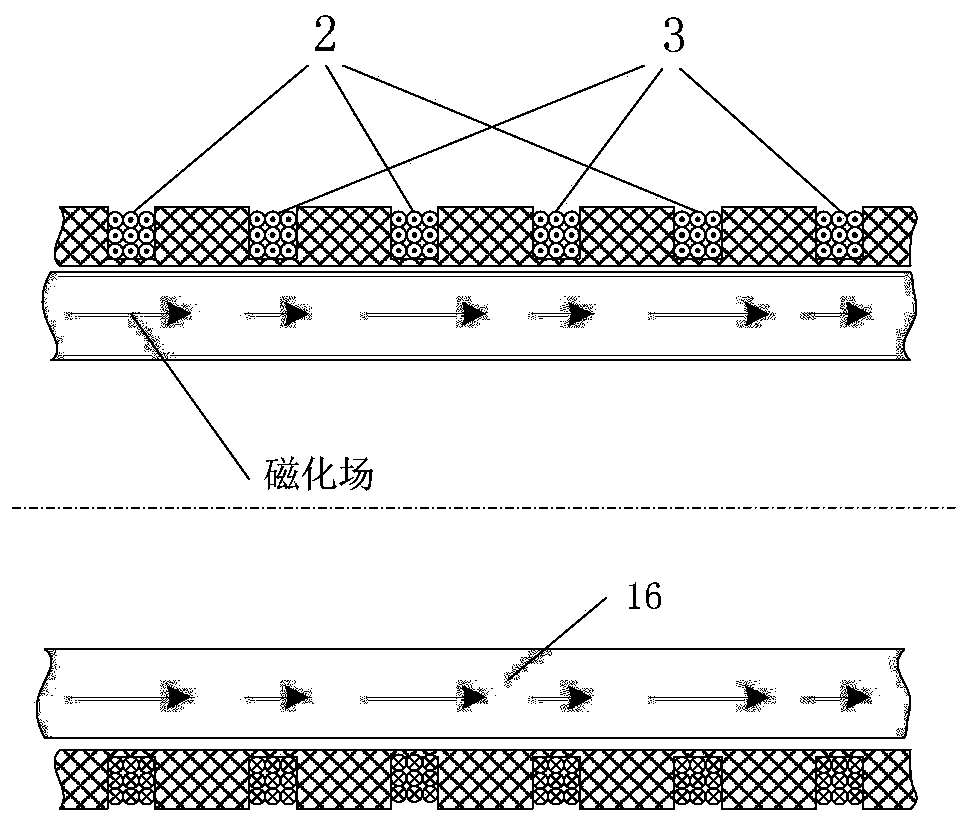

[0053] The electromagnetic ultrasonic transducer 5 is a coil self-excited ferromagnetic pipeline electromagnetic ultrasonic transducer provided in Embodiment 1, which is installed on the ferromagnetic pipeline 16 to be tested;

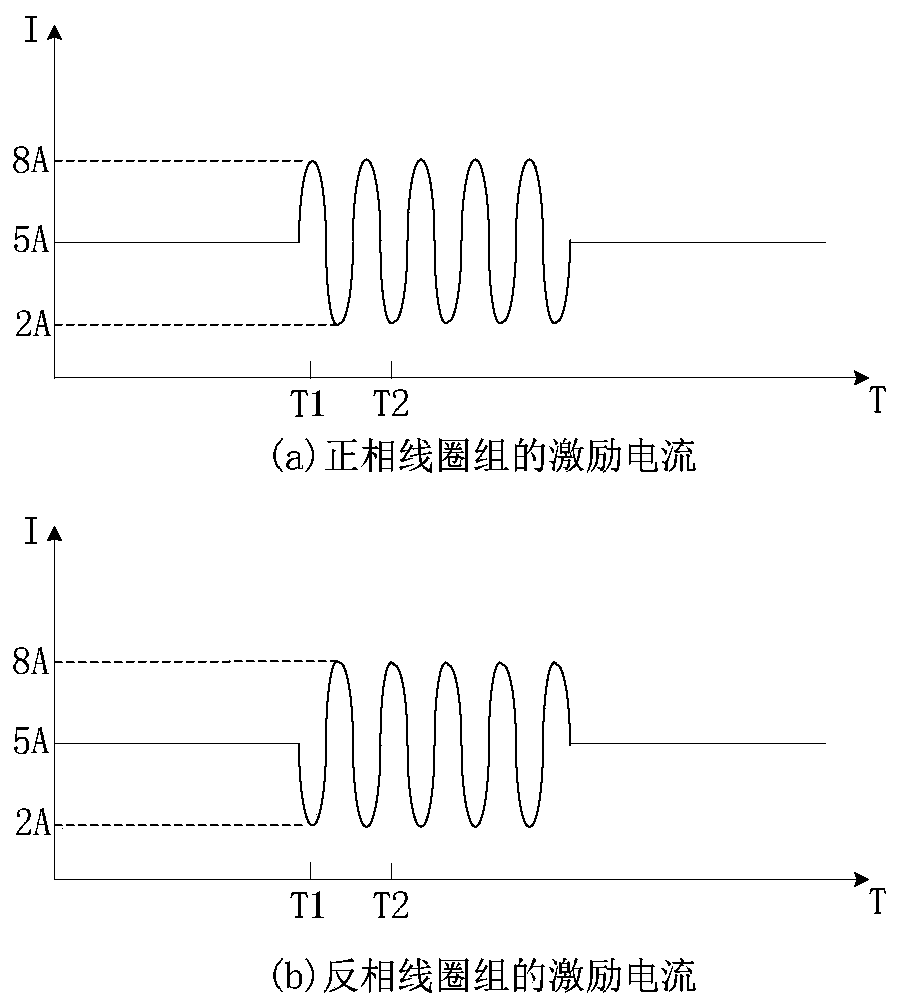

[0054] The high-power constant current source 6 is preferably EPS-3020MD constant current source current to generate two 5A DC bias currents; the first output is connected to the positive phase coil group 2 of the electromagnetic ultrasonic transducer 5, and the second output is connected to the electromagnetic ultrasonic The ant...

Embodiment 3

[0062] see Image 6 , which is a structural block diagram of Embodiment 3 of the present invention, provides a coil self-excitation ferromagnetic pipeline electromagnetic ultrasonic receiving device, including: electromagnetic ultrasonic transducer 5, high-power constant current source 6, coupling capacitor 12, signal conditioning circuit 13, acquisition circuit 14, host computer 15, wherein,

[0063] The electromagnetic ultrasonic transducer 5 is a coil self-excited ferromagnetic pipeline electromagnetic ultrasonic transducer provided in Embodiment 1, which is installed on the ferromagnetic pipeline 16 to be tested;

[0064] The high-power constant current source 6 is preferably EPS-3020MD constant current source current to generate two 5A DC bias currents; the first output is connected to the positive phase coil group 2 of the electromagnetic ultrasonic transducer 5, and the second output is connected to the electromagnetic ultrasonic The anti-phase coil group 3 of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com