Silicon carbide junction barrier Schottky diode with trench structure

A junction barrier Schottky, silicon carbide technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced breakdown voltage of devices, deterioration of reverse breakdown characteristics, etc., to reduce electric field spikes , the effect of increasing forward conduction current and increasing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

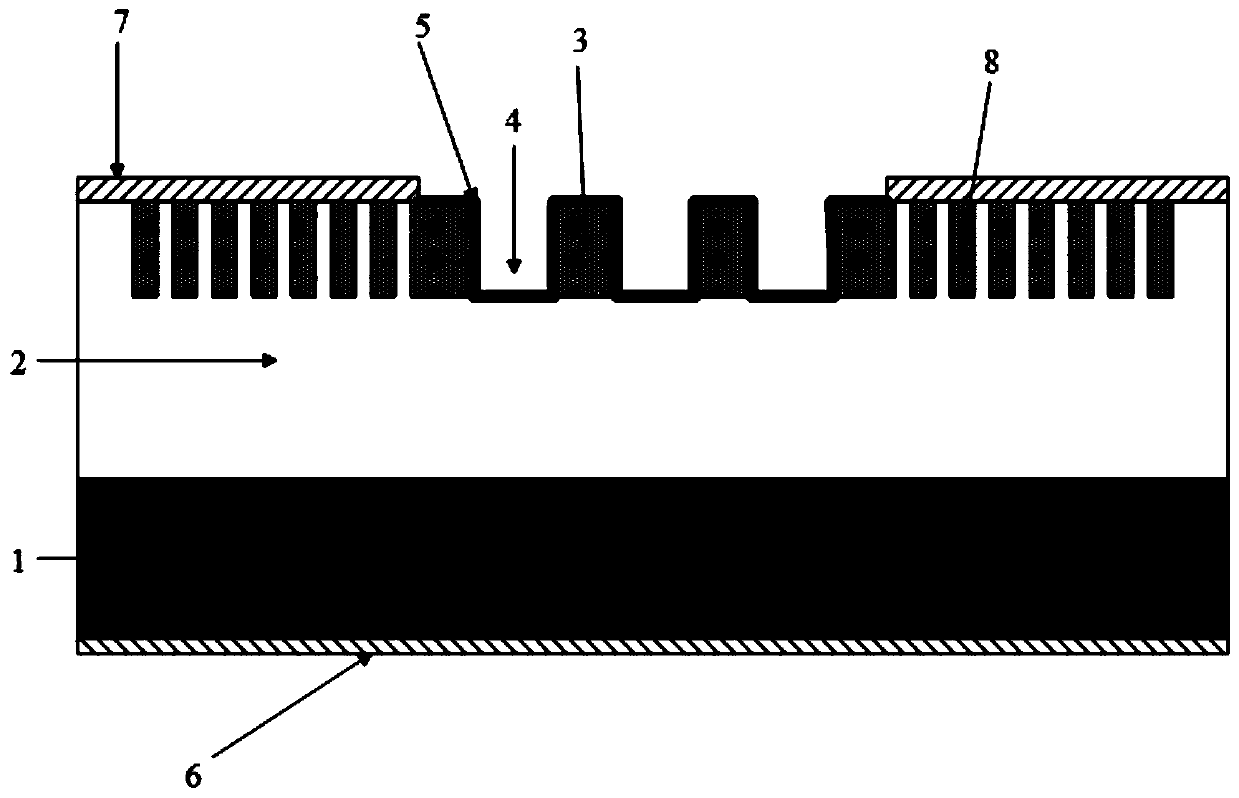

[0036] Such as figure 2 As shown, a silicon carbide junction barrier Schottky diode with a trench structure provided by the first embodiment of the present invention includes an ohmic contact electrode 6, a silicon carbide N+ substrate 1, a silicon carbide N- epitaxial layer 2, and SiO2 Isolation dielectric 7, Schottky contact electrode 5, multiple P+ injection regions 3 and multiple P+ field limiting rings 8;

[0037] Ohmic contact electrode 6, silicon carbide N+ substrate 1 and silicon carbide N- epitaxial layer 2 are sequentially stacked from bottom to top; multiple P+ implantation regions 3 are arranged at intervals on the upper layer of silicon carbide N- epitaxial layer 2; multiple P+ fields The confinement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com