Cr-Sb phase change storage material and preparation and application thereof

A phase-change storage, cr-sb technology, applied in the field of microelectronics, can solve problems such as difficulty in amorphization, and achieve the effects of fast crystallization, simple components, and reduced preparation process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

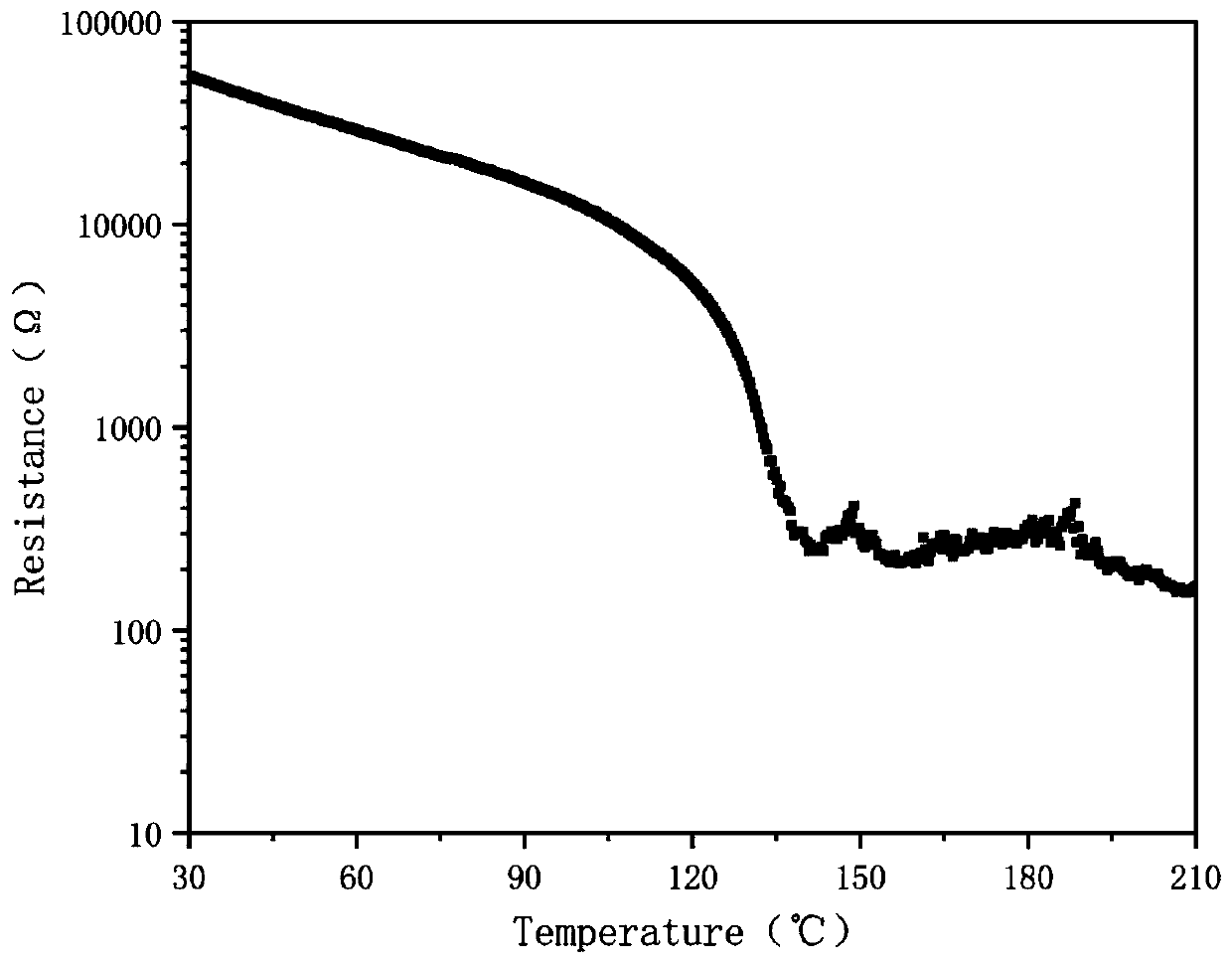

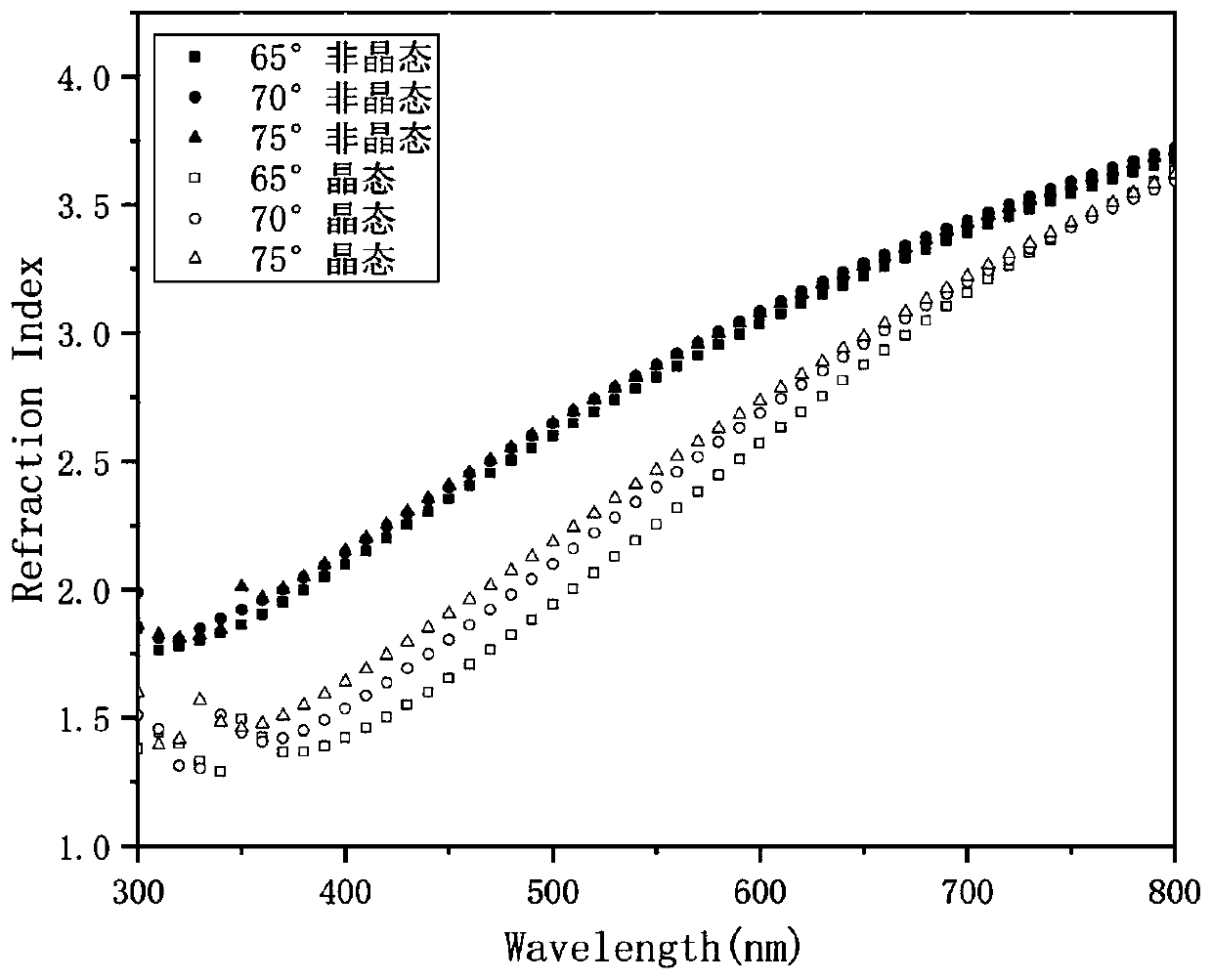

[0035] The general formula of the chemical composition of the nano-Cr-Sb phase-change film material used for phase-change memory prepared in this embodiment is Cr 10 Sb 90 .

[0036] The Cr-Sb nano film material is prepared by magnetron sputtering; during the preparation, high-purity argon is introduced as the sputtering gas, the sputtering pressure is 0.5 Pa, and the background vacuum is required to be 10 -4 Below Pa; the sputtering target is Cr 10 Sb 90 The alloy target is sputtered by a DC source, the sputtering power is 32W, and the target base distance is set to 120mm. Concrete preparation method comprises the following steps:

[0037] (1) Select SiO with a size of 1cm*1cm 2 / Si(100) substrate, clean the surface and back, remove dust particles, organic and inorganic impurities. Specifically, the following steps may be included:

[0038] (1-1) Cut out 1cm*1cm of SiO with a silicon wafer knife 2 / Si (100) substrate, used as the substrate for sputtering;

[0039] (1...

Embodiment 2

[0054] The general formula of the chemical composition of the nano-Cr-Sb phase-change film material used for phase-change memory prepared in this embodiment is Cr 5 Sb 95 .

[0055]The Cr-Sb nano film material is prepared by magnetron sputtering; during the preparation, high-purity argon is introduced as the sputtering gas, the sputtering pressure is 0.5 Pa, and the background vacuum is required to be 10 -4 Below Pa; the sputtering target is Cr 5 Sb 95 The alloy target is sputtered by a DC source, the sputtering power is 32W, and the target base distance is set to 120mm. Concrete preparation method comprises the following steps:

[0056] (1) Select SiO with a size of 1cm*1cm 2 / Si(100) substrate, clean the surface and back, remove dust particles, organic and inorganic impurities. Specifically, the following steps may be included:

[0057] (1-1) Cut out 1cm*1cm of SiO with a silicon wafer knife 2 / Si (100) substrate, used as the substrate for sputtering;

[0058] (1-2)...

Embodiment 3

[0070] The general formula of the chemical composition of the nano-Cr-Sb phase-change film material used for phase-change memory prepared in this embodiment is Cr 30 Sb 70 .

[0071] The Cr-Sb nano film material is prepared by magnetron sputtering; during the preparation, high-purity argon is introduced as the sputtering gas, the sputtering pressure is 0.5 Pa, and the background vacuum is required to be 10 -4 Below Pa; the sputtering target is Cr 30 Sb 70 The alloy target is sputtered by a DC source, the sputtering power is 32W, and the target base distance is set to 120mm. Concrete preparation method comprises the following steps:

[0072] (1) Select SiO with a size of 1cm*1cm 2 / Si(100) substrate, clean the surface and back, remove dust particles, organic and inorganic impurities. Specifically, the following steps may be included:

[0073] (1-1) Cut out 1cm*1cm of SiO with a silicon wafer knife 2 / Si (100) substrate, used as the substrate for sputtering;

[0074] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com