A kind of silicon carbon negative electrode material and preparation method

A negative electrode material, silicon carbon technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of large volume change and silicon-based material volume change, and achieve strong oxidation resistance, good stability, and enhanced electrical conductivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

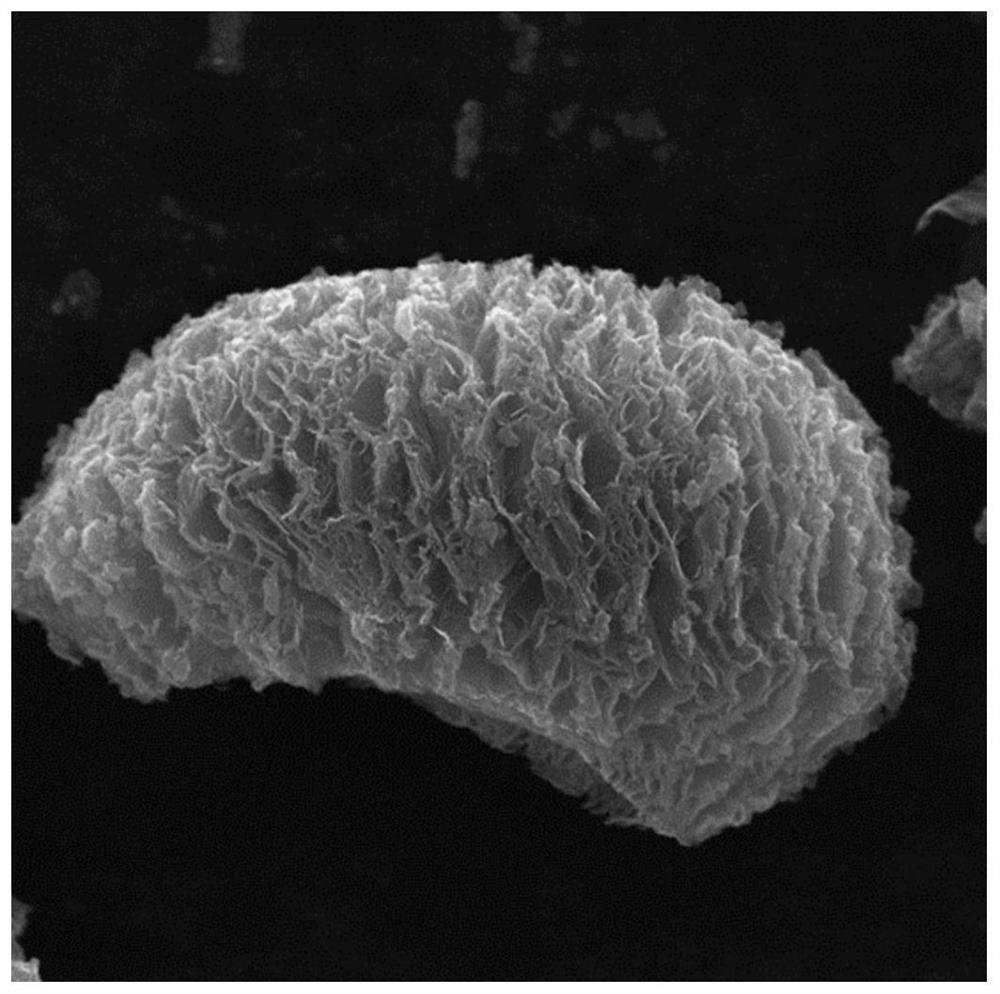

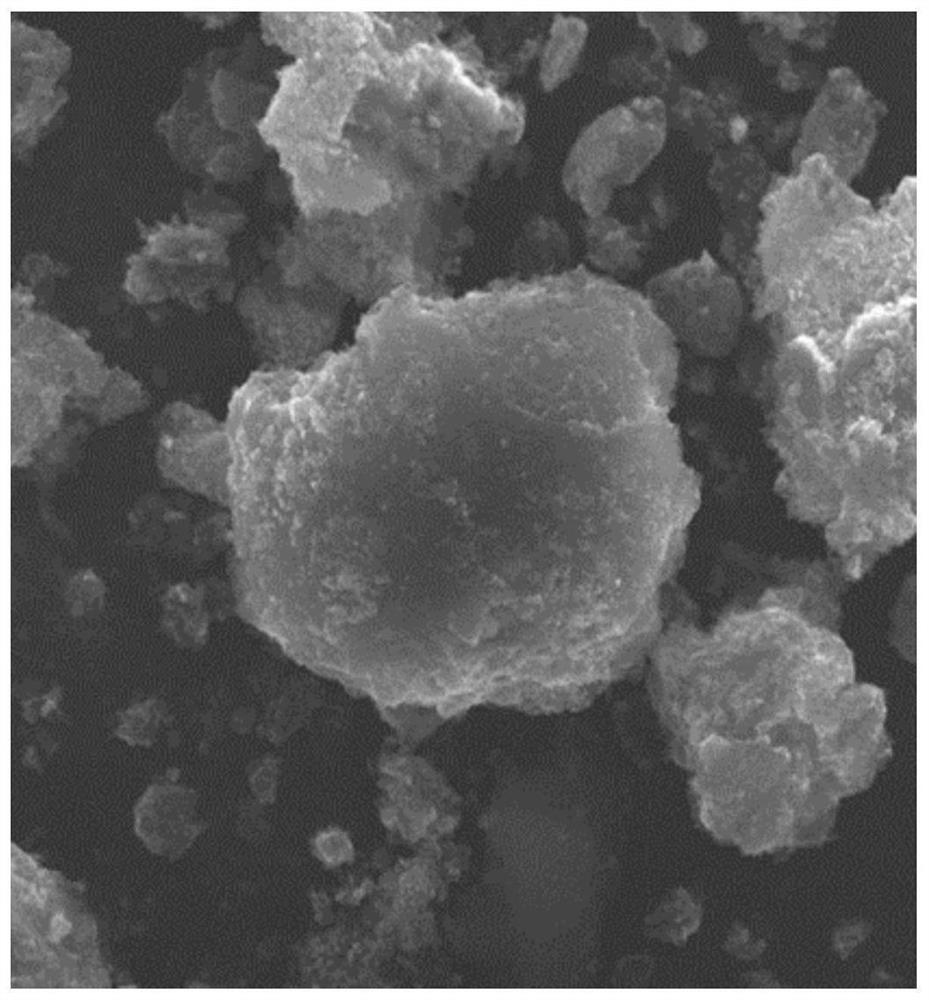

[0053]This example provides a silicon-carbon negative electrode material, which includes a catalytic graphite layer and three-dimensional expanded graphite wrapped inside the catalytic graphite layer, and nano-silicon is embedded in the three-dimensional expanded graphite.

[0054] Wherein, the catalytic graphite layer refers to the catalytic graphite layer formed after metal catalysis.

Embodiment 2

[0056] This example provides the preparation method of expanded graphite, specifically:

[0057] The commercial material mesophase carbon microspheres are prepared into graphite oxide by the classic Hummer’s method, and then the graphite oxide is sintered in a tube furnace at 950°C for 10 to 30 minutes to obtain expanded graphite.

[0058] Wherein, the preparation method of graphite oxide is:

[0059] (1) Put mesocarbon microspheres and 2.5 g of sodium nitrate in a 1000 mL three-necked flask, add sulfuric acid, and stir for 15 min;

[0060] (2) Lower the reaction temperature to 4°C, slowly add 16gKMnO 4 , stirring at low temperature for 3h;

[0061] (3) Raise the reaction temperature to 35°C, stir at medium temperature for 3h, and add 200mL of deionized water;

[0062] (4) The reaction temperature was raised to 98°C, and 15 mL of 30% H 2 o 2 , stirring at high temperature for 5h;

[0063] (5) cooling to room temperature, centrifuging and washing and separating the reacti...

Embodiment 3

[0065] This example provides the preparation method of silicon carbon negative electrode material, and the steps include:

[0066] S1: After mixing the expanded graphite, nano-silicon, carbon source and catalyst precursor, heating and evaporating to dryness to obtain the precursor;

[0067] S2: sintering the precursor in step S1 under an inert atmosphere and then washing and drying to obtain a silicon-carbon negative electrode material.

[0068] In step S1, during the mixing process of the nano-silicon and the expanded graphite, the nano-silicon enters into the three-dimensional layered structure of the expanded graphite.

[0069] In step S2, the carbon source is sintered under the action of the metal catalyst to generate catalytic graphite, which is evenly coated on the surface of the three-dimensional expanded graphite.

[0070] Wherein, the average particle size D50 of nano-silicon is less than 100nm.

[0071] Carbon sources include glucose, sucrose, starch, citric acid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

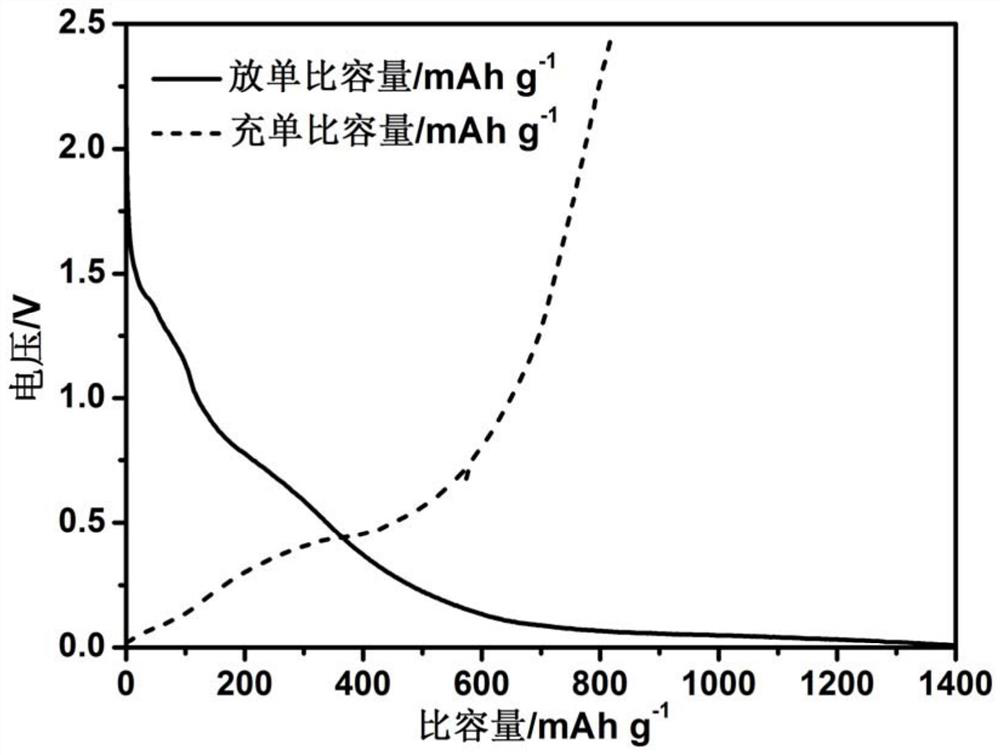

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com