Heat-exchange sulfuric acid catalytic decomposition reactor and catalytic method thereof

A catalytic decomposition and reactor technology, applied in chemical instruments and methods, chemical/physical processes, hydrogen production, etc., can solve problems such as unsuccessful production and operation of sulfuric acid decomposition reactors, equipment design, manufacturing science and engineering problems , to achieve the effects of sulfuric acid corrosion resistance, increase equipment throughput, heat exchange and heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

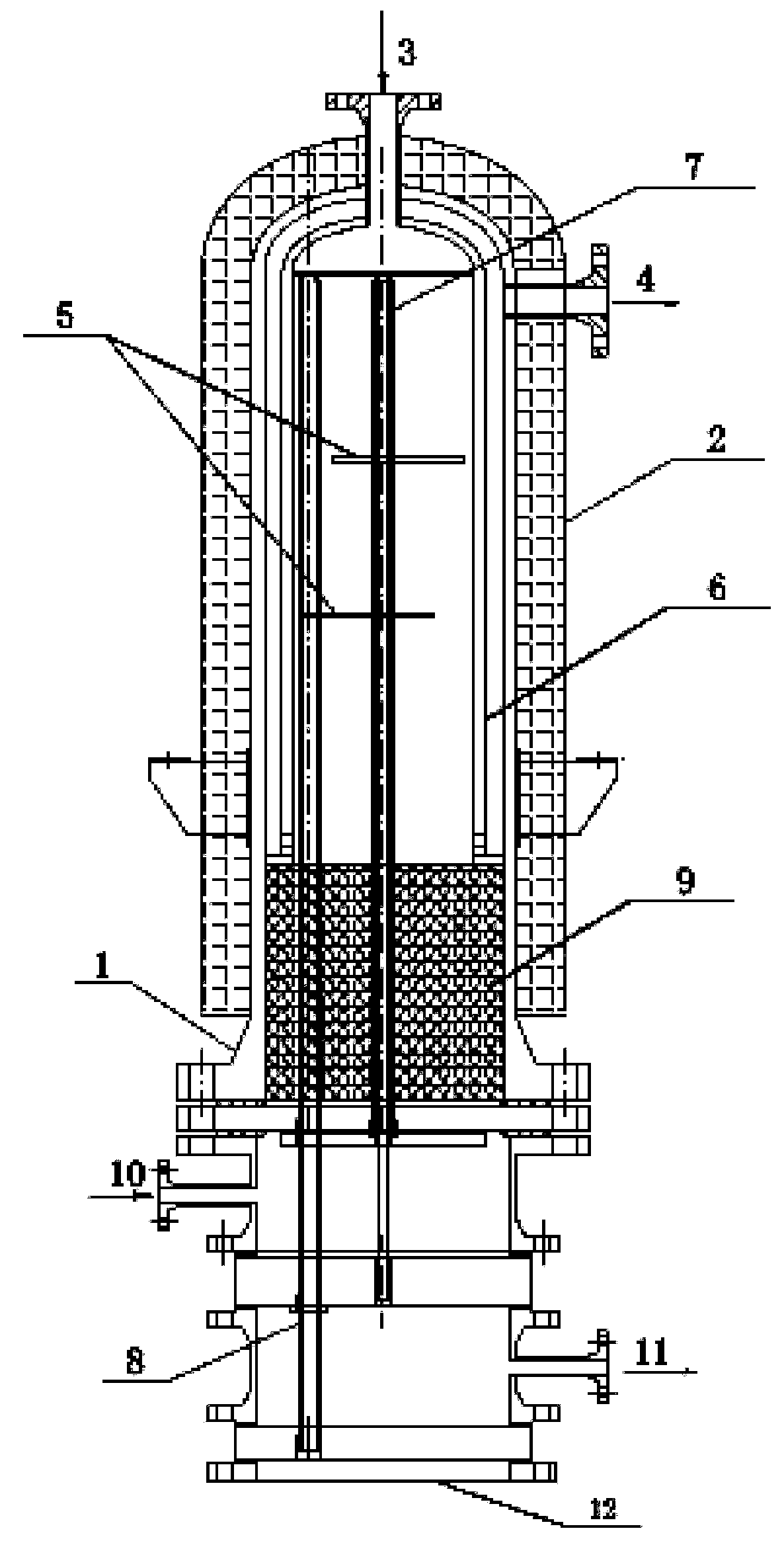

Embodiment 1

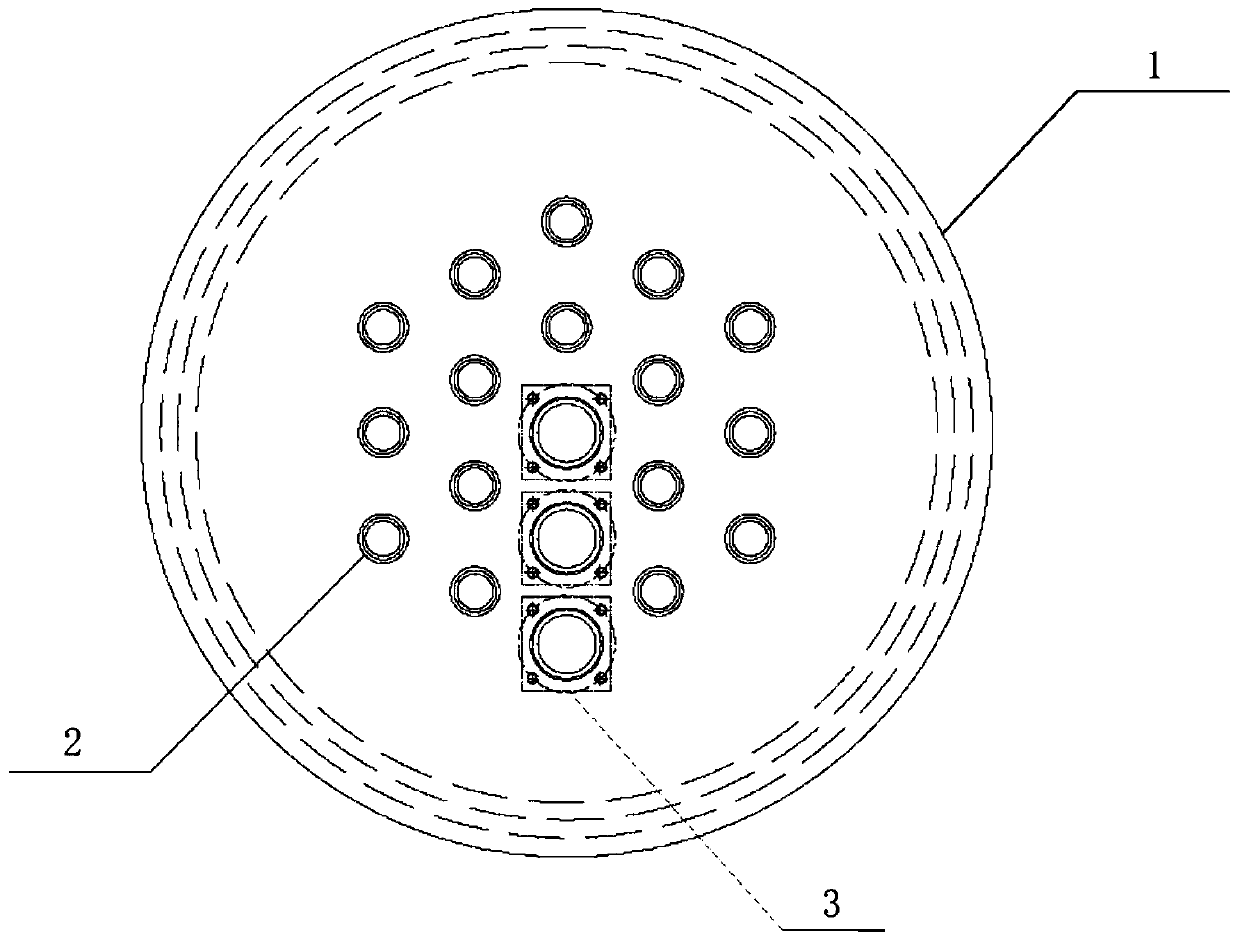

[0044] A gas-heated heat-exchanging sulfuric acid decomposition reactor according to the present invention, the reactor shell made of alloy 800H is used as the shell of the shell-and-tube heat exchanger, and the inlet and outlet of high-temperature gas are arranged on it. The gas inlet is connected to a deflector, and several partitions are connected to the deflector, which can make the high-temperature gas flow in the reactor along the designed path and flow velocity distribution, and realize a reasonable temperature distribution. The internal heat exchange type sulfuric acid decomposition component of the bayonet tube made of silicon carbide and other materials resistant to high temperature, high pressure and strong corrosion is installed in the holes of the two porous end plates. The sulfuric acid decomposition component adopts winding seal. In the reactor, 10 bayonet tubes are installed in the regenerative silicon carbide bayonet tube internal heat exchange type sulfuric a...

Embodiment 2

[0048] A gas-heated heat-exchanging sulfuric acid decomposition reactor according to the present invention, the reactor shell made of alloy 800H is used as the shell of the shell-and-tube heat exchanger, and the inlet and outlet of high-temperature gas are arranged on it. The gas inlet is connected to a deflector, and several partitions are connected to the deflector, which can make the high-temperature gas flow in the reactor along the designed path and flow velocity distribution, and realize a reasonable temperature distribution. The internal heat exchange type sulfuric acid decomposition component of the bayonet tube made of silicon carbide and other materials resistant to high temperature, high pressure and strong corrosion is installed in the holes of the two porous end plates. The heat exchange sulfuric acid decomposition component adopts winding seal. In the reactor, 19 bayonet tubes are installed in the regenerative silicon carbide bayonet tube internal heat exchange t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com