Pre-reactor for esterification of ethylene glycol

A technology of ethylene glycol ester and reactor, applied in the field of ethylene glycol esterification pre-reactor, can solve the problems of high investment and operation cost, low use efficiency, large system resistance, etc., achieve small air flow resistance, improve conversion rate, Ease of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other.

[0028] The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

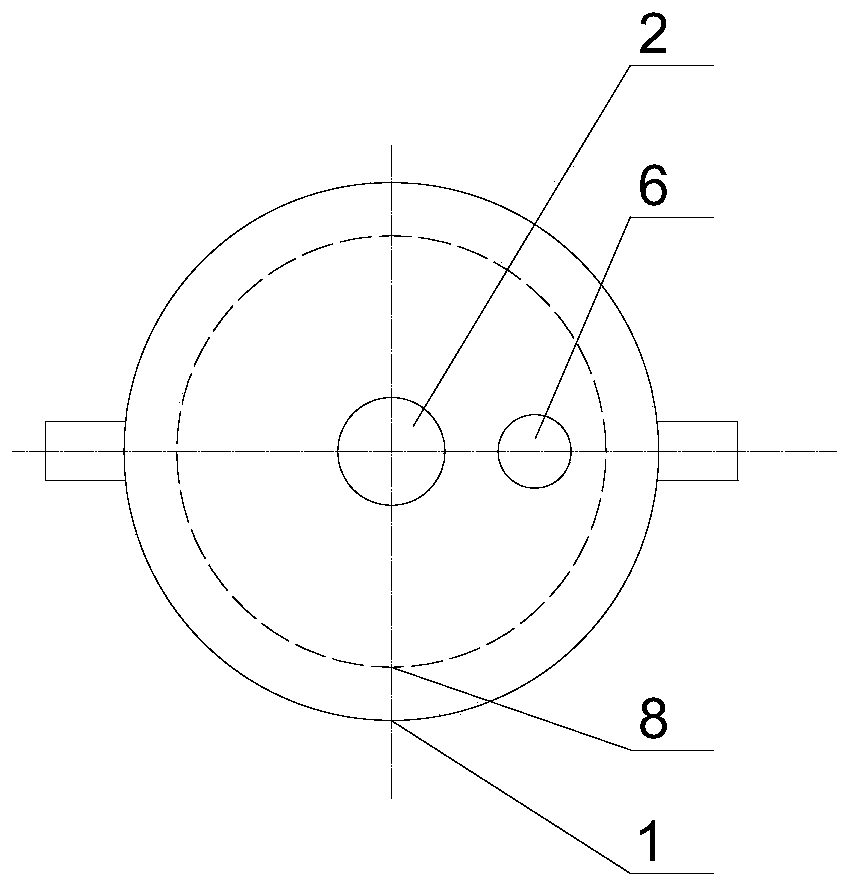

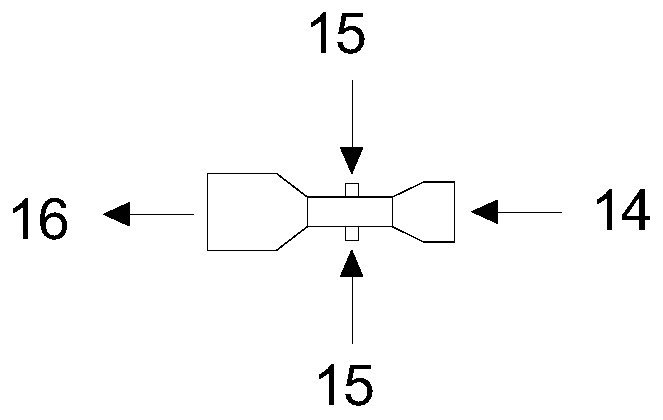

[0029] combine figure 1 , figure 2 , the present invention provides a kind of ethylene glycol esterification pre-reactor, and described ethylene glycol esterification pre-reactor comprises shell 1, and the air inlet 2 that is used to pass into synthetic gas is opened on described shell 1 and An air outlet 3 for discharging the reacted gas. The housing 1 is provided with a reaction channel 4 that communicates with the air inlet 2 and can be introduced into oxygen. The reaction channel 4 is surrounded by a A heat exchange tube 5 that extends in the radial direction of the body 1 and can be cooled by a cooling medium, the inlet of the heat exchange tube 5 communicates with the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com