Method for high-yield preparation of bio-oil by using cow dung as raw material

A bio-oil, high-yield technology, applied in the direction of fat production, oil/fatty acid recovery from waste, fuel, etc., to achieve the effect of reducing dependence, mild reaction conditions, and strong industrial potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

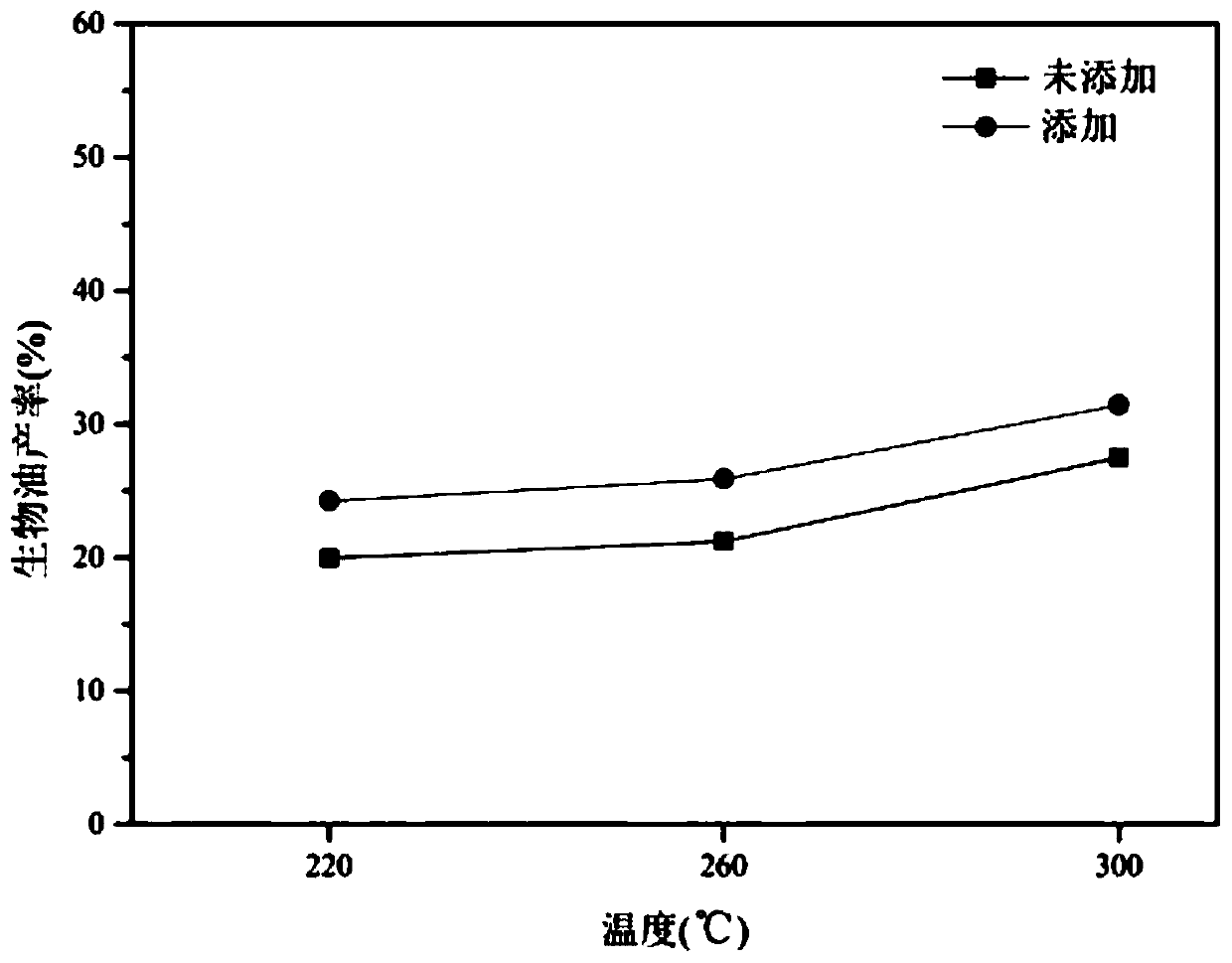

Embodiment 1

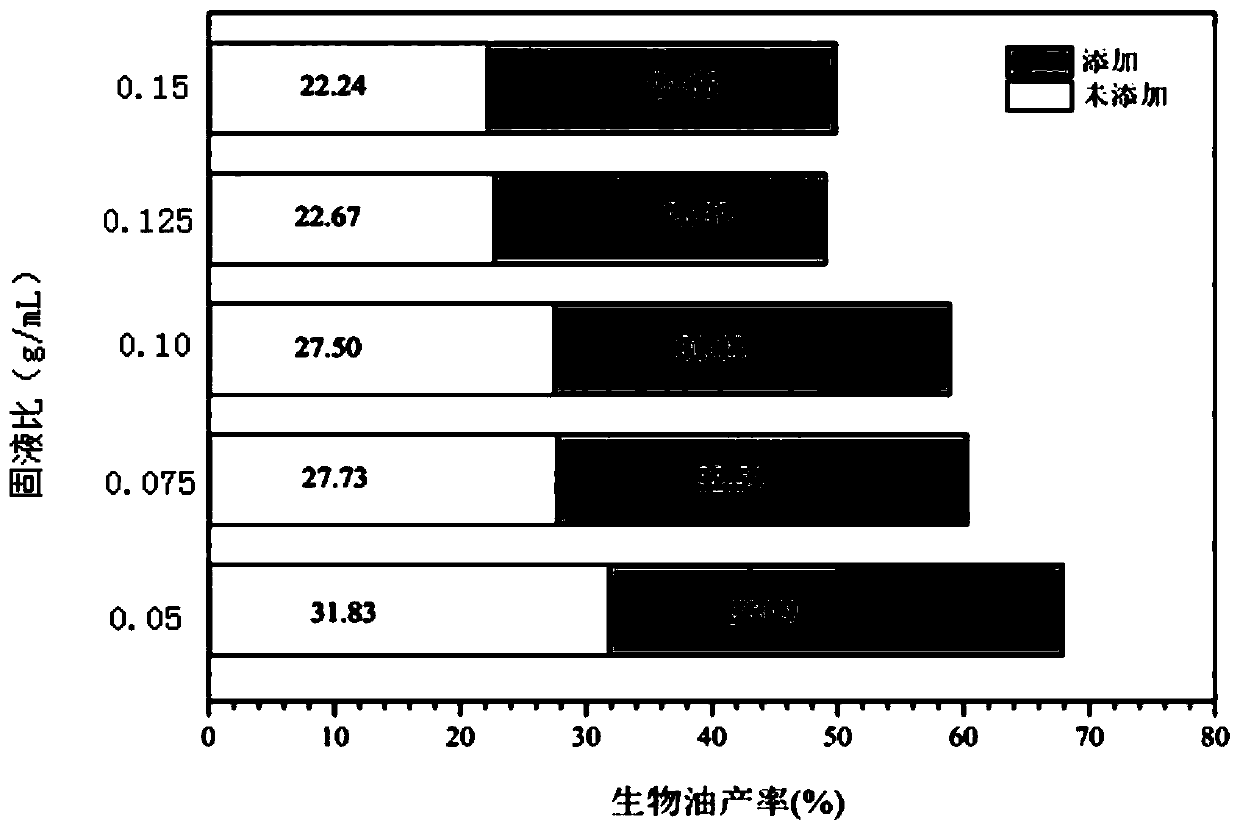

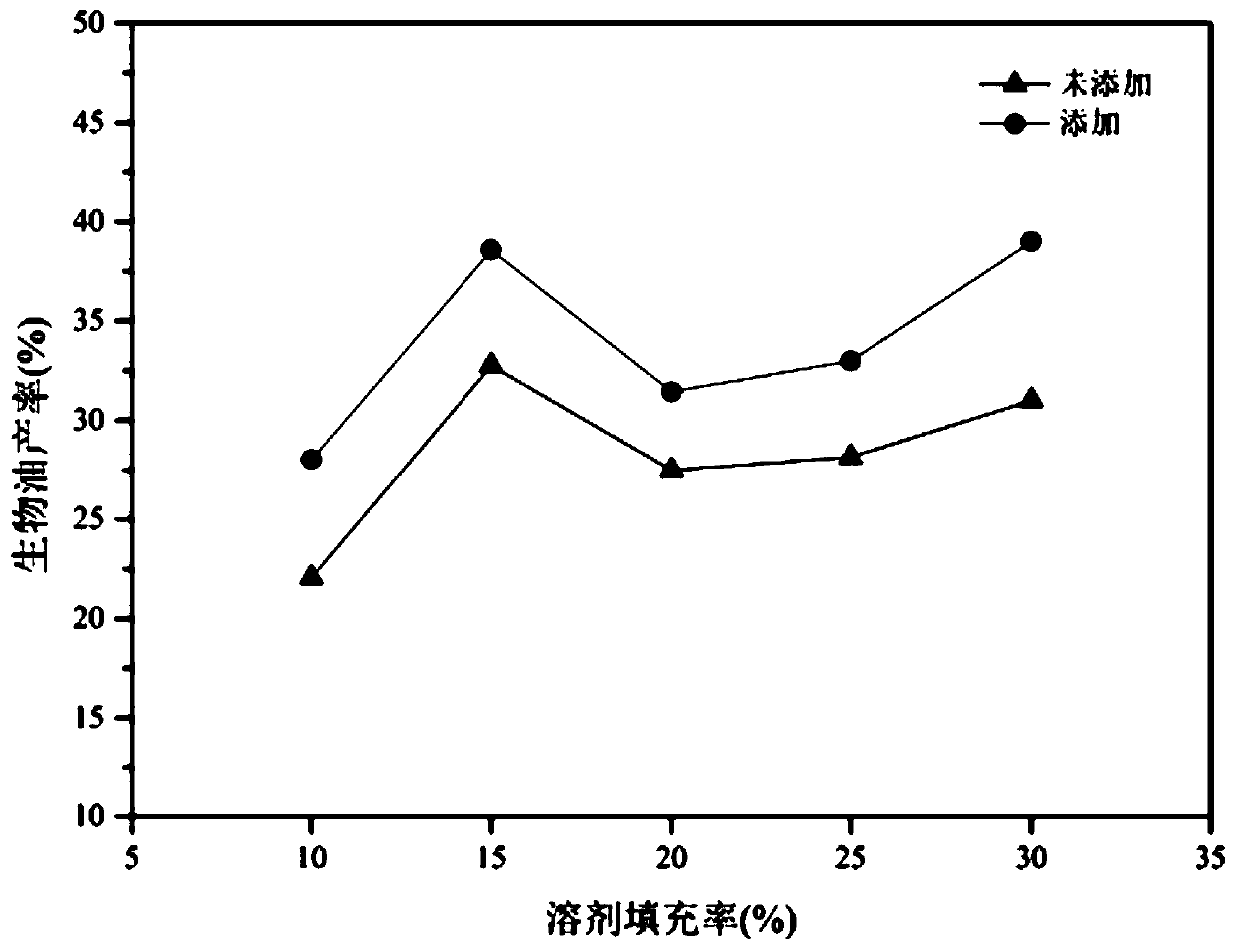

[0052] A method for preparing bio-oil with high yield using cow dung as raw material, specifically comprising the following steps:

[0053] a, pretreatment: dry the fresh cow dung to a moisture content of 10%, then crush the cow dung through an 80-mesh sieve;

[0054] b. Sub- / supercritical liquefaction: the treated cow dung and absolute ethanol have a solid-to-liquid ratio of 0.1g / mL, the solvent absolute ethanol has a filling rate of 20%, and calcium oxide of 7% of the total amount of cow dung raw materials Mix the fragments evenly and pour them into the reaction kettle; seal the reaction kettle, the design pressure is 12.5MPa, the heating voltage is 250V, and the set liquefaction temperature is 220°C; the reaction kettle is heated up, and the temperature reaches the set liquefaction temperature. Stop heating after the reaction is over, and cool the reactor to room temperature with condensed water when the temperature of the reactor is about 100°C;

[0055] c. Solid-liquid s...

Embodiment 2

[0058] The difference between this example and Example 1 is that the liquefaction temperature is set at 260° C., and the prepared bio-oil sample is denoted as S2.

Embodiment 3

[0060] The difference between this example and Example 1 is that the liquefaction temperature is set at 300° C., and the prepared bio-oil sample is denoted as S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com