A kind of preparation method of graphene reinforced copper-based composite material

A copper-based composite material, graphene technology, applied in metal processing equipment, transportation and packaging, coating and other directions, can solve the problems of small material bearing capacity, no significant increase in electrical and thermal conductivity, etc., to reduce magnetic adsorption and improve mechanical properties. and physical properties, the effect of strong magnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] An embodiment of the present invention provides a method for preparing a graphene-reinforced copper-based composite material, the method for preparing the composite material comprising:

[0049] Prepare flake copper powder;

[0050] Graphene is nickel-plated to obtain nickel-plated graphene;

[0051] The flake copper powder and the nickel-plated graphene are ball-milled to obtain a mixed powder;

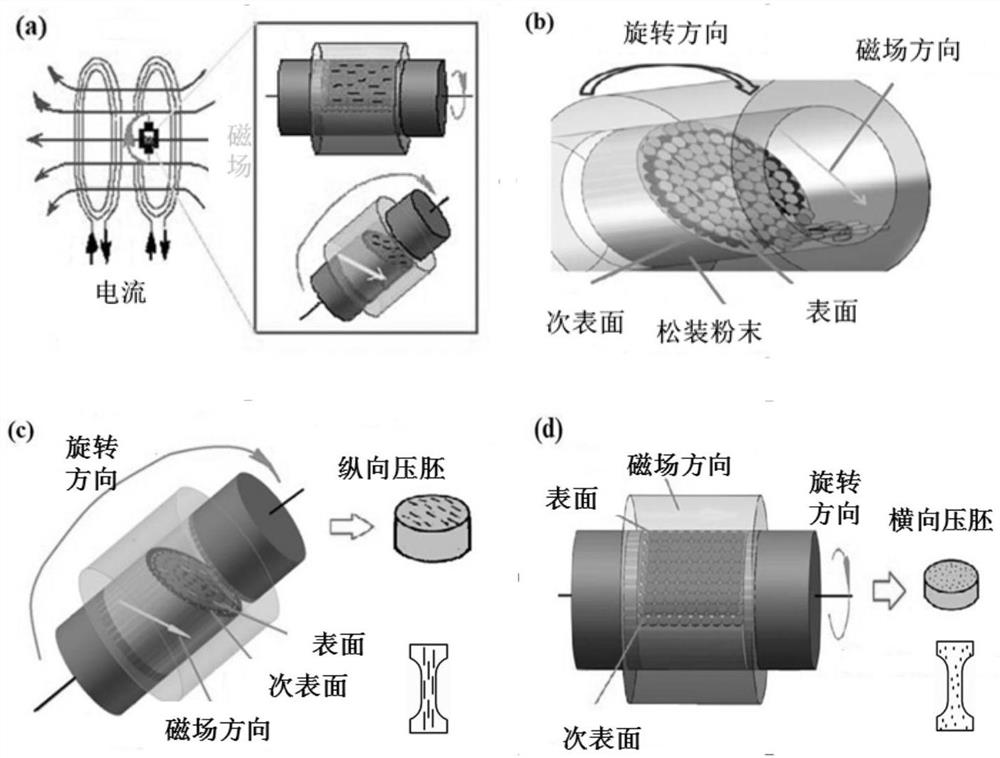

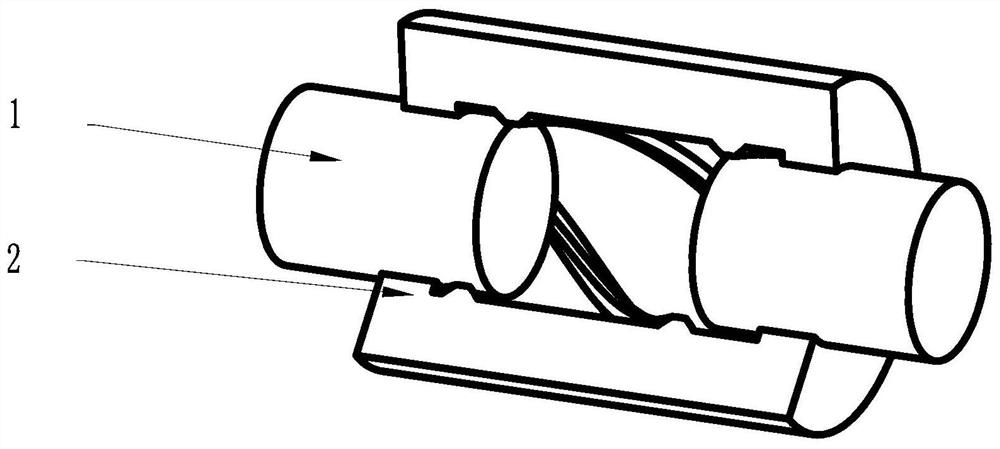

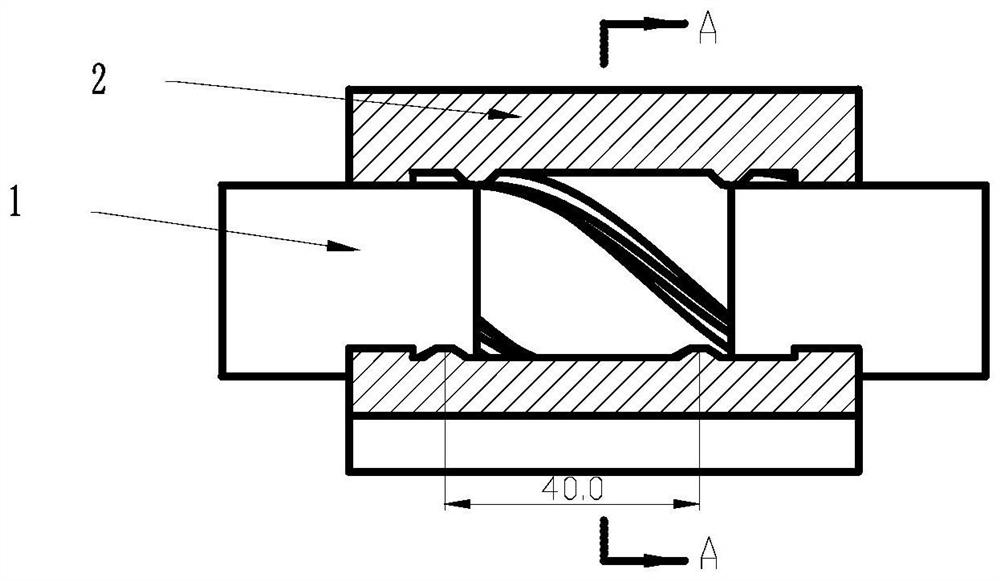

[0052] performing countercurrent rotational orientation treatment on the mixed powder under a magnetic field to obtain a composite powder compact;

[0053] The composite powder compact is sintered to obtain a graphene-reinforced copper-based composite material.

[0054] Above-described embodiment adopts pre-prepared flake copper powder, and flake copper powder is conducive to the dispersion of graphene; Carry out nickel plating to graphene simultaneously, increases the paramagnetism of graphene; The mixing of flake copper powder and nickel-plated graphene The powder is subj...

Embodiment 1

[0075] A preparation method of graphene-reinforced copper-based composite material, comprising the following steps:

[0076] To prepare flake copper powder, put gas-atomized spherical copper powder with a particle size of 45-109 μm into a ball mill tank, and add absolute ethanol as a process control agent to avoid excessive cold welding of copper powder during ball milling. The material ratio is 10:1, the ball milling speed is 250rpm, and the ball milling time is 10h in order to obtain copper powders with different sheet diameters. After ball milling, the copper powders are vacuum-dried at 60°C for 12h. Then, the dried powder is reduced with hydrogen in a tube-type reduction furnace, the reduction temperature is 400°C, and the reduction time is 3 hours; the reduced flake powder is screened with 200-mesh and 300-mesh sieves to obtain the particle size 48-75 μm flake powder to obtain the final flake copper powder.

[0077] For the sensitization treatment of graphene, first, the...

Embodiment 2

[0085] A preparation method of graphene-reinforced copper-based composite material, comprising the following steps:

[0086] To prepare flake copper powder, put gas-atomized spherical copper powder with a particle size of 45-109 μm into a ball mill tank, and add absolute ethanol as a process control agent to avoid excessive cold welding of copper powder during ball milling. The material ratio is 10:1, the ball milling speed is 250rpm, and the ball milling time is 10h in order to obtain copper powders with different sheet diameters. After ball milling, the copper powders are vacuum-dried at 60°C for 12h. Then, the dried powder is reduced with hydrogen in a tube-type reduction furnace, the reduction temperature is 400°C, and the reduction time is 3 hours; the reduced flake powder is screened with 200-mesh and 300-mesh sieves to obtain the particle size 48-75 μm flake powder to obtain the final flake copper powder.

[0087] For the sensitization treatment of graphene, first, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com