Polyimide/silica composite material and preparation method thereof

A polyimide and silica technology, applied in coating, fiber treatment, textiles and papermaking, etc., can solve the problem of difficulty in coating silica, and achieve the effect of improving antigenic oxygen capacity and maintaining mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The first aspect of the present invention provides a kind of preparation method of polyimide / silicon dioxide composite material, and this method comprises the following steps:

[0032] (1) contacting the polyimide matrix with lye to obtain the polyimide matrix treated with lye;

[0033] (2) The dispersion liquid containing the silicon source is placed in the reactor, the polyimide substrate treated with alkali solution is placed above the dispersion liquid, the reactor is closed, and the temperature of the dispersion liquid is raised to a reaction temperature of 100-160°C, preferably raising the temperature of the dispersion to a reaction temperature of 110-150°C, and keeping at the reaction temperature for 2-24 hours, preferably 3-20 hours, more preferably 10-20 hours;

[0034] (3) heat-treating the polyimide matrix obtained in step (2).

[0035] According to the method of the present invention, in step (1), the polyimide matrix is contacted with the lye, so that th...

Embodiment 1

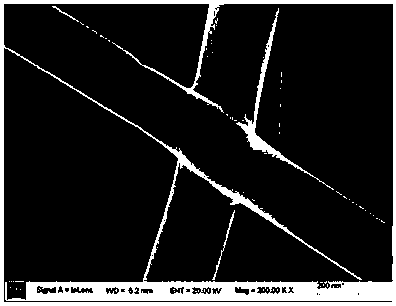

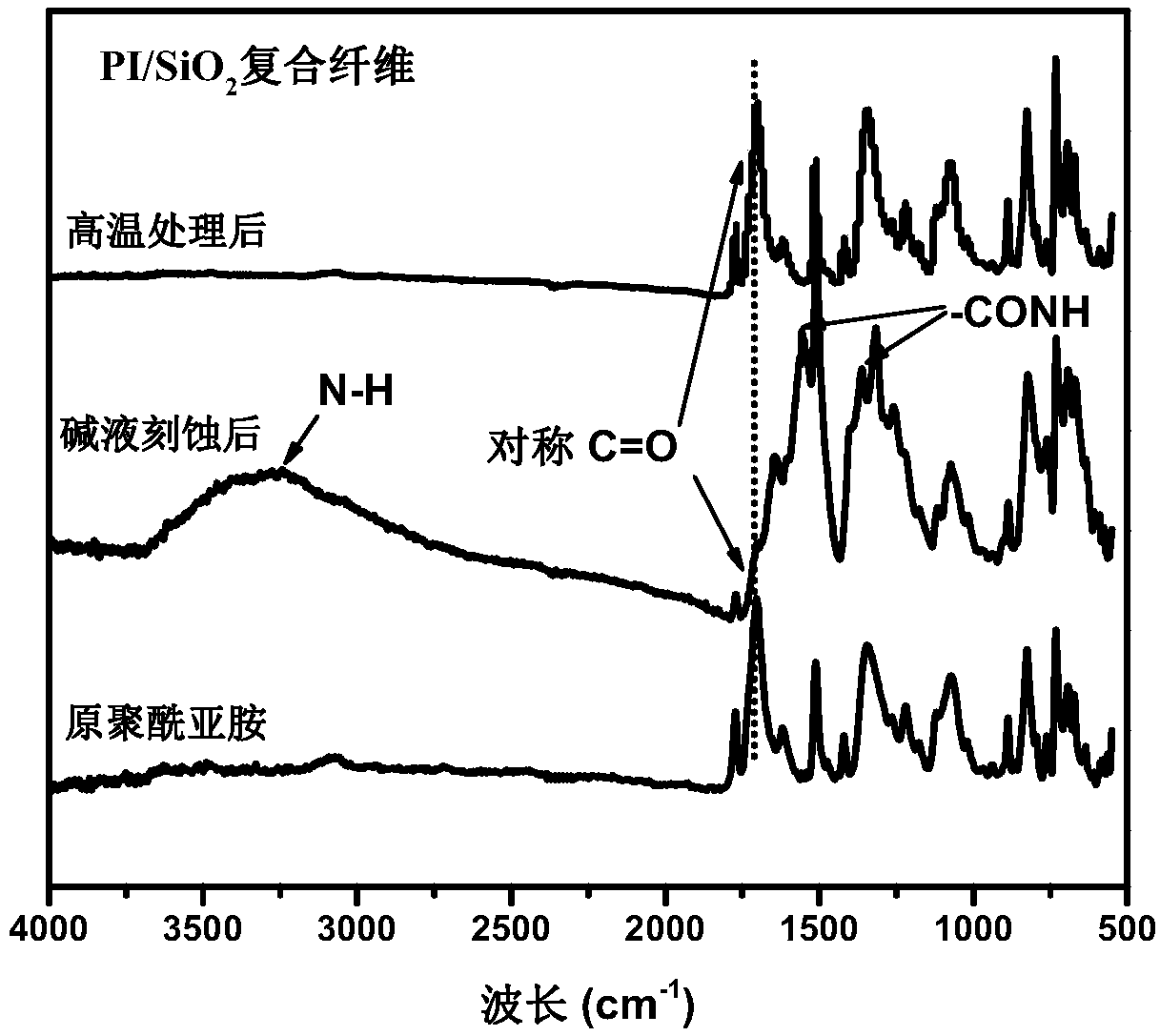

[0065] (1) Put the polyimide fiber in deionized water and ultrasonically clean it for 30 minutes to remove impurities on the surface of the substrate. After drying, immerse it in a 5mol / L potassium hydroxide aqueous solution at room temperature (25°C, the same below). ℃ water bath at constant temperature for 4 minutes, then rinse with a large amount of deionized water to remove the potassium hydroxide attached to the surface, and dry in the air; after the lye treatment, the imide bond on the fiber surface is hydrolyzed to produce amide groups and carboxyl-COO -. The polyimide fiber used as raw material and the polyimide fiber treated with potassium hydroxide were characterized by infrared, and the results were as follows: Figure 1a As shown, compared with the polyimide fiber as raw material, the amide structure absorption peak appeared in the infrared spectrogram of the polyimide fiber treated with potassium hydroxide, and the symmetrical stretching peak of the carbonyl of the...

Embodiment 2

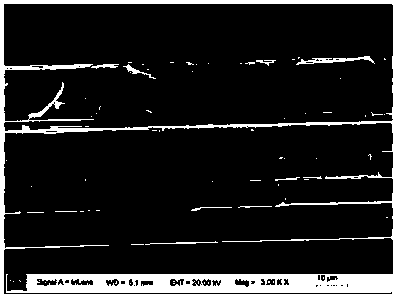

[0069] (1) Put the polyimide film in deionized water and ultrasonically clean it for 20 minutes to remove impurities on the surface of the substrate. After drying, immerse it in 7mol / L potassium hydroxide aqueous solution at room temperature, and treat it at a constant temperature in a water bath at 30°C for 8 minutes, then Rinse with plenty of deionized water to remove potassium hydroxide adhering to the surface, and air dry. The polyimide film as raw material and the polyimide film treated with potassium hydroxide were characterized by infrared, as shown in Figure 2a As shown, compared with the polyimide film as raw material, the amide structure absorption peak appears in the infrared spectrogram of the polyimide film treated with potassium hydroxide, and the symmetrical stretching peak of the carbonyl of the imine ring decreases simultaneously, It shows that the imine ring opens, indicating that carboxyl -COO- is formed on the surface of the polyimide film treated with pot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com