Micro-droplet treatment device and using method thereof

A processing device and micro-droplet technology, which is applied in the field of microfluidics, can solve the problems of inability to realize on-line cultivation of microorganisms, inability to control the cultivation and screening of microorganism droplets on-line, and inability to realize detection functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

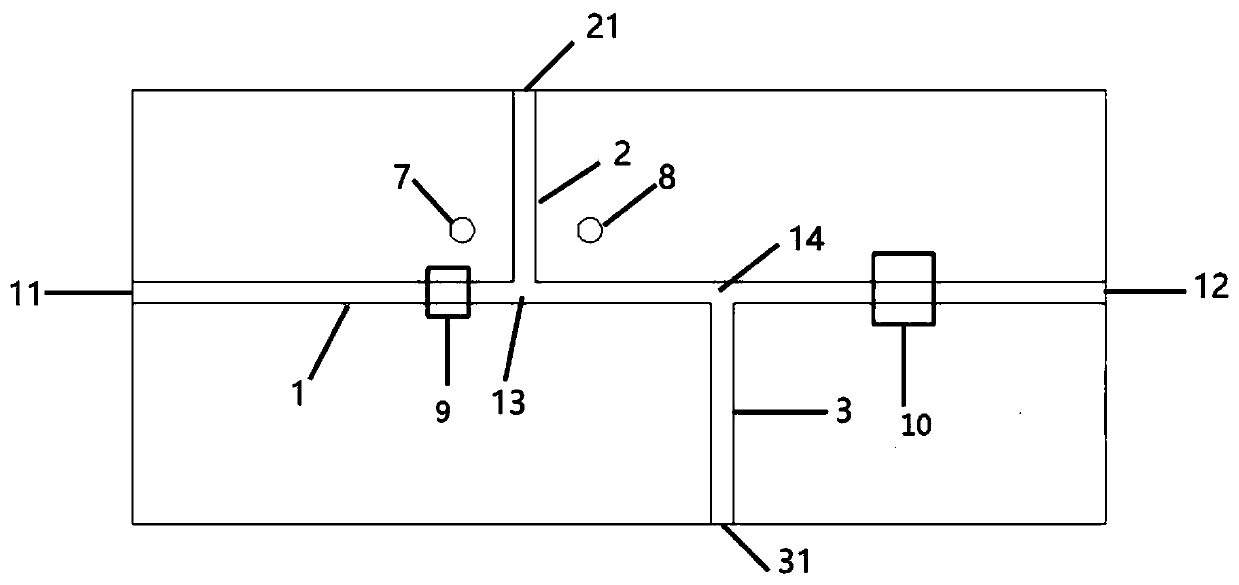

[0178] The first pipe, the second pipe, and the third pipe are pipes formed in the chip substrate. The size of the chip substrate is 3cm*5cm*4mm (length*width*thick). The material used for the chip substrate is PMMA. The first pipe, the second pipe, and the third pipe are square pipes with a cross-sectional area of 1mm 2 (its side length is 1mm), the first pipeline communicates with the second pipeline and the third pipeline respectively, and the first communication part between the first pipeline and the second pipeline is located at the upstream of the second communication part between the first pipeline and the third pipeline , the distance between the first communication part and the second communication part is 1.5 mm. The pipeline is full of oily medium.

[0179] The first connection port of the first pipeline is connected to the syringe pump A, the second connection port is connected to the first rotary valve, the third connection port of the second pipeline is conne...

Embodiment 2

[0187] Adopt the same material as embodiment 1 such as Figure 4 As shown, a microfluidic chip is formed. In Example 2, the substrate has a length of 7.5 cm and a width of 5 cm.

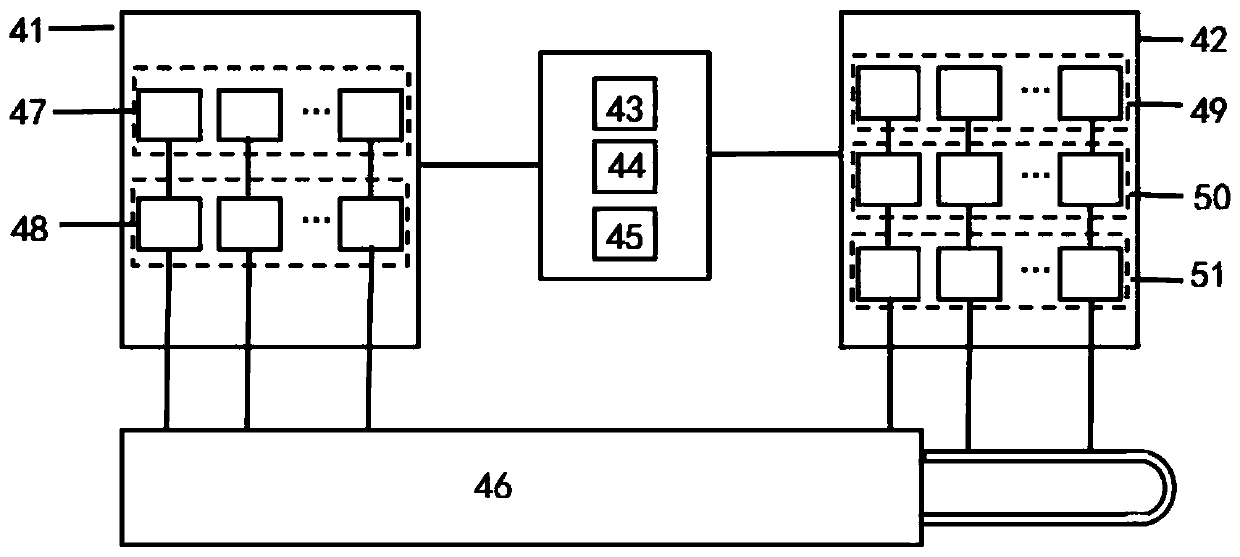

[0188] In addition, in Example 2, the configuration of the sampling system is as follows Figure 8 As shown, the microfluidic chip is connected with 3 sample injection systems I and 3 sample injection systems II, wherein the power source and valves are the same as those in Example 1.

[0189] In Embodiment 2, before the chip is used, the sampling system I fills the chip with the oil phase, and then through the sampling system II connected to the second pipeline 2, the second pipeline 2 is injected into the second pipeline 2 for inoculation in a sterilized state. The bacteria liquid forms water-in-oil droplets at the first communication part 13. After the sample injection is completed, the second pipeline 2 is filled with the oil phase again. Next, under the action of the power source of the sampl...

Embodiment 3

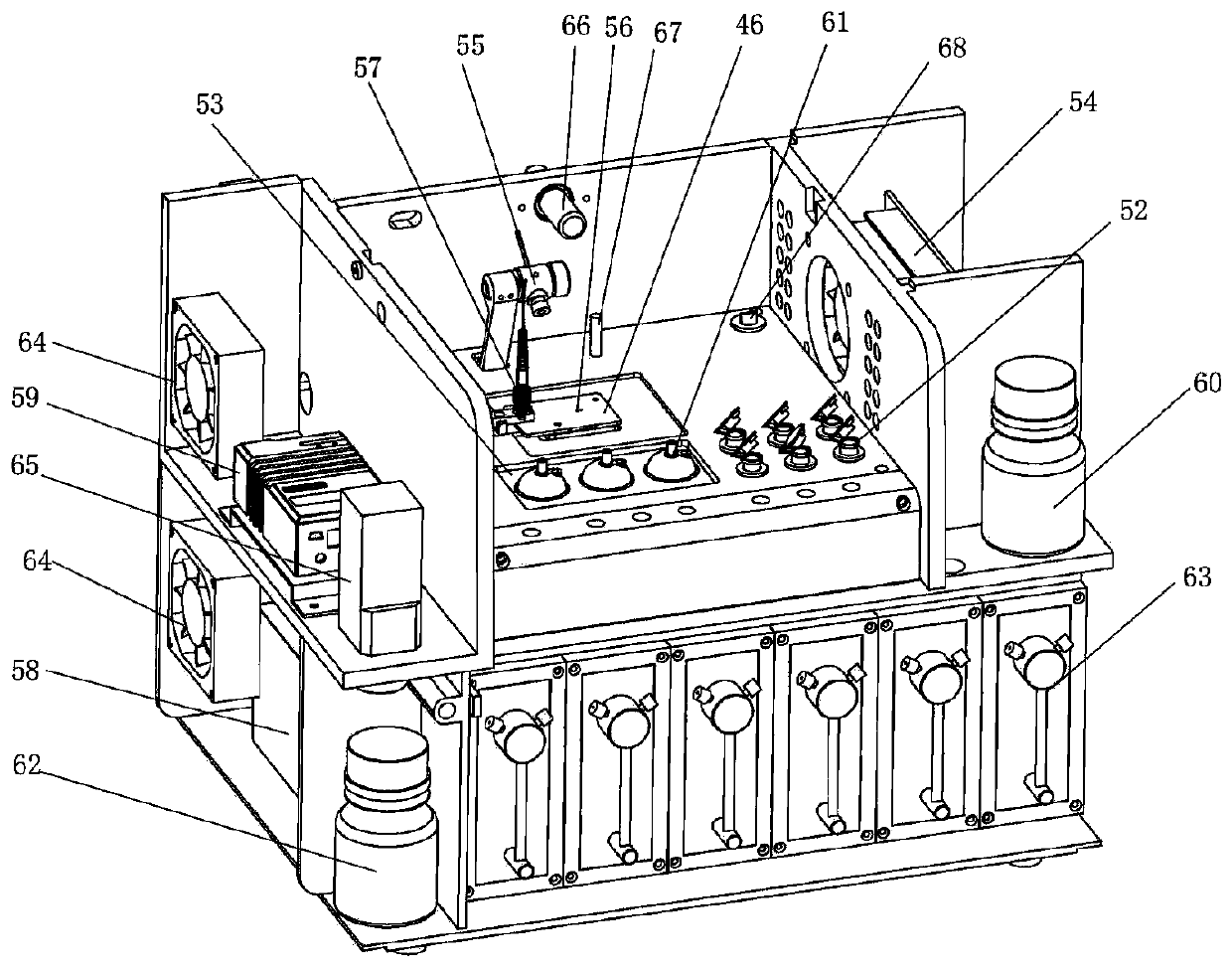

[0193] In Example 3, such as figure 2 As shown, the sample injection system, microfluidic chip system, culture system, temperature control system, droplet recognition system, and droplet detection system are all set in one box. through as figure 2 In the setup shown, the microfluidic chip system in Example 2 is used to realize droplet segmentation, fusion and new microbial droplet culture.

[0194] Among them, the sampling system includes such as Figure 8 Three sampling systems I, three sampling systems II, valves and waste bottles are shown. The sampling system I is composed of a power pump and an oil phase bottle, and the sampling system II is composed of a power pump, an oil phase bottle and a sample buffer. The oil phase medium stored in the oil phase bottle used in the sampling system I is the same as the oil phase medium stored in the oil phase bottle in the sampling system II. In a specific embodiment, the oil phase bottle can be shared. In this example, if figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com