Automatic control system for feeding through pneumatic conveying

An automatic control system and pneumatic conveying technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of affecting feed efficacy, pellet feed is easy to be crushed, etc., to avoid biological safety problems, low crushing rate, The effect of long conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

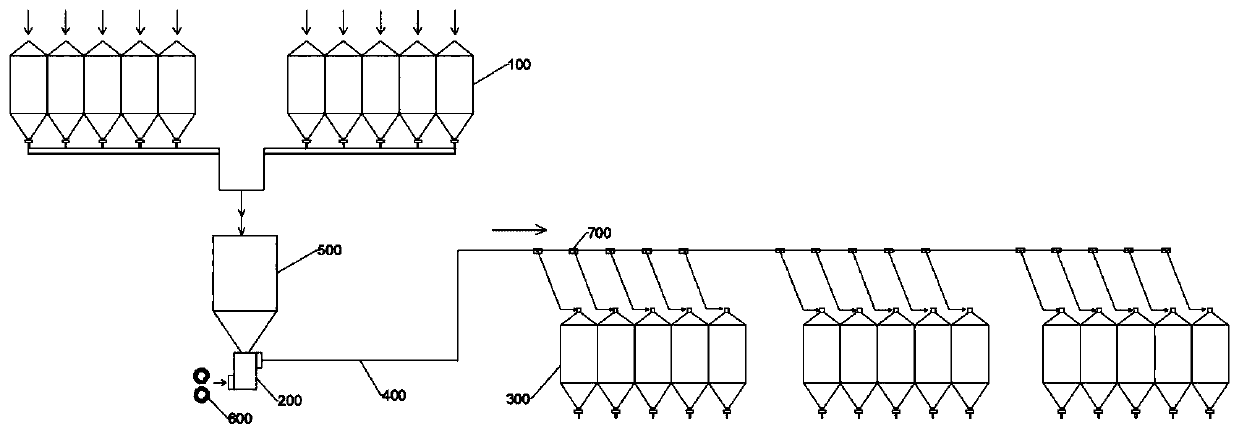

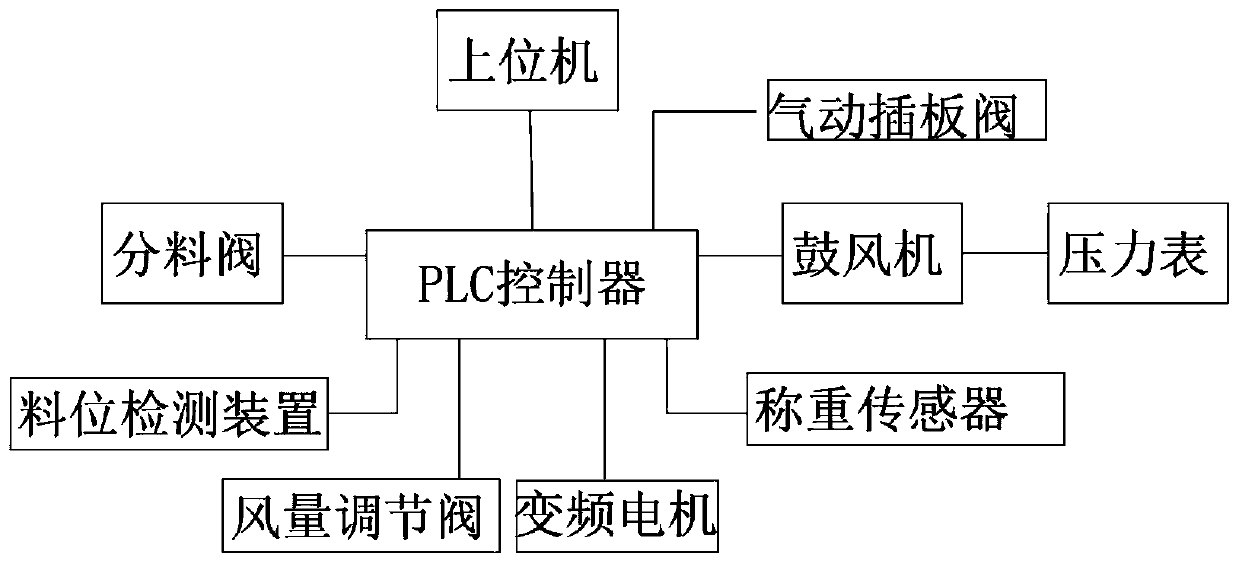

[0029] Such as figure 1 , figure 2 As shown, an automatic control system for feeding materials by means of pneumatic conveying includes a control system and a controlled system, the control system includes a PLC controller, and the PLC controller is electrically connected to a host computer system, and the host computer system It includes an industrial computer, a display and a memory connected to the industrial computer, and the display is used to display the interface of the state of the controlled system;

[0030] The controlled system includes a main material tower 100, an intermediate tower 500, a gas-material mixing chamber 200, and a material distribution tower 300 arranged sequentially along the feeding direction through a conveying pipeline 400;

[0031] The controlled system also includes a blower 600, and the air outlet of the blower 600 communicates with the gas material mixing chamber 200;

[0032] The branch pipe of the delivery pipeline 400 connected to the m...

Embodiment 2

[0037] This embodiment is a further optimization made on the basis of Embodiment 1. Specifically, an unloader is provided at the bottom of the intermediate tower 500, and the unloader is driven by a frequency conversion motor; the bottom of the unloader and the gas material The mixing chamber 200 is connected, and the frequency conversion motor is connected with the PLC controller for electrical signals.

Embodiment 3

[0039] This embodiment is a further optimization made on the basis of Embodiment 2. Specifically, three load cells are arranged on the weighing bucket, and a three-point weighing mode is implemented. The load cells are electrically connected to the PLC controller. signal connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com