Method for in-situ synthesis of montmorillonite/gold nanorod composite materials

A technology of gold nanorods and composite materials, which is applied in the field of metal powder processing, can solve the problems of uneven distribution of nanoparticles and low loading of nanoparticles, and achieve the effect of strong repeatability, short time consumption, and green and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

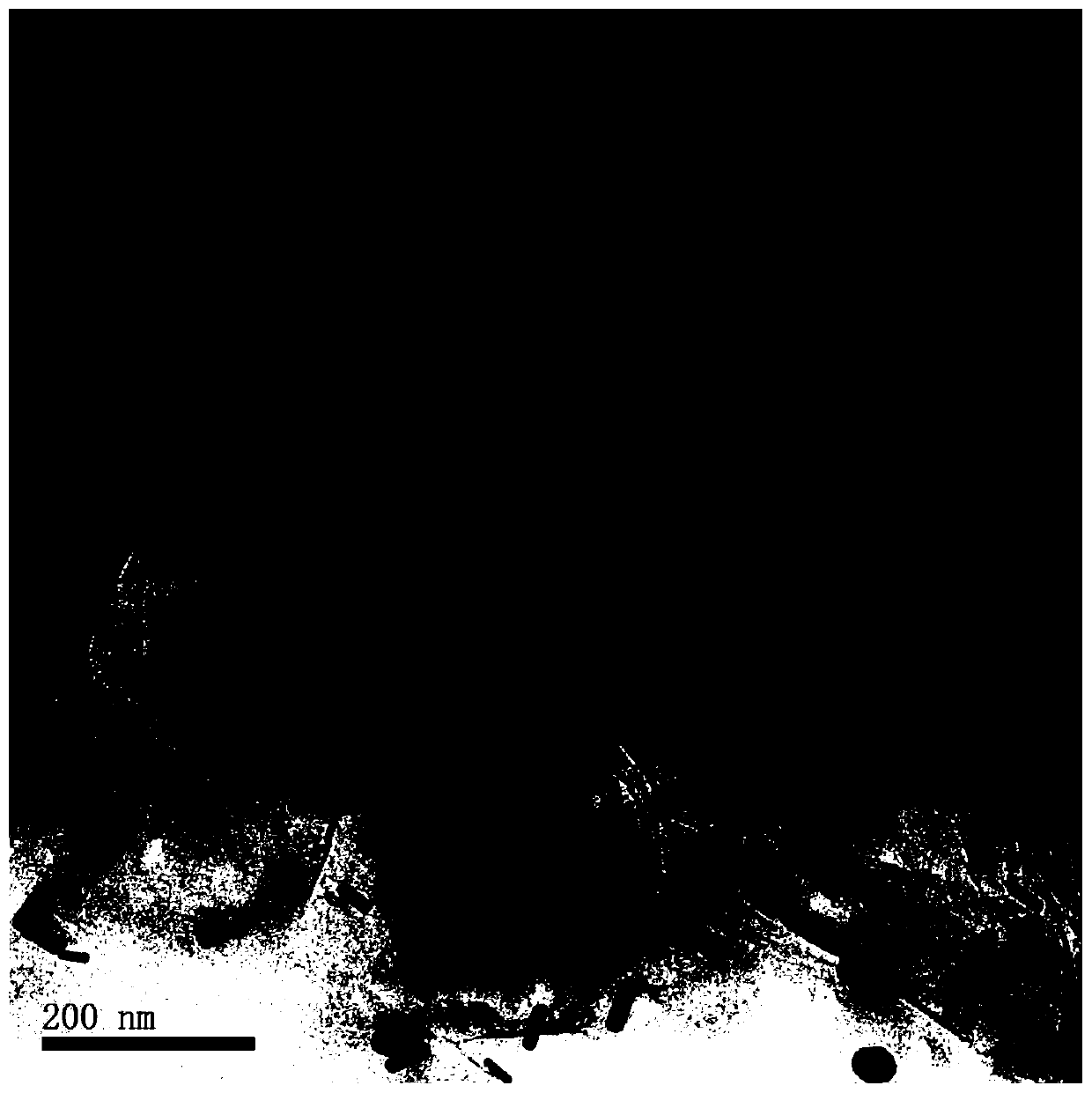

[0020] A method for in-situ synthesis of montmorillonite / gold nanorod composite material, the steps are as follows:

[0021] Step 1, add 10 mL of montmorillonite solution with a concentration of 1.0 mg / mL to 50 mL of cetyltrimethylammonium bromide aqueous solution with a concentration of 0.2 mol / L, mix well, then add 3.125 mL with a concentration of 24 mmol / L chloroauric acid aqueous solution and 3mL concentration of 4mmol / L silver nitrate aqueous solution to obtain mixed solution A;

[0022] Step 2, add 1.2mL of ascorbic acid aqueous solution with a concentration of 43mmol / L to the mixed solution A, add 1m gold seed solution after the solution becomes colorless and transparent, and let it stand at a constant temperature of 28°C for 9 hours to obtain the mixed solution B;

[0023] Step 3, centrifuge the mixed solution B at 12000rpm for 20min, take the precipitate, and resuspend the precipitate in ultrapure water to obtain the montmorillonite / gold nanorod composite material.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com