High-whiteness wollastonite powder and preparation method thereof

A technology of wollastonite powder and high whiteness, which is applied in silicate, alkaline earth metal silicate, grain treatment, etc., and can solve the problems of affecting the whiteness of wollastonite firing, limited application of ceramic products, and extremely high requirements. , to achieve the effect of eliminating secondary iron pollution, better energy saving effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

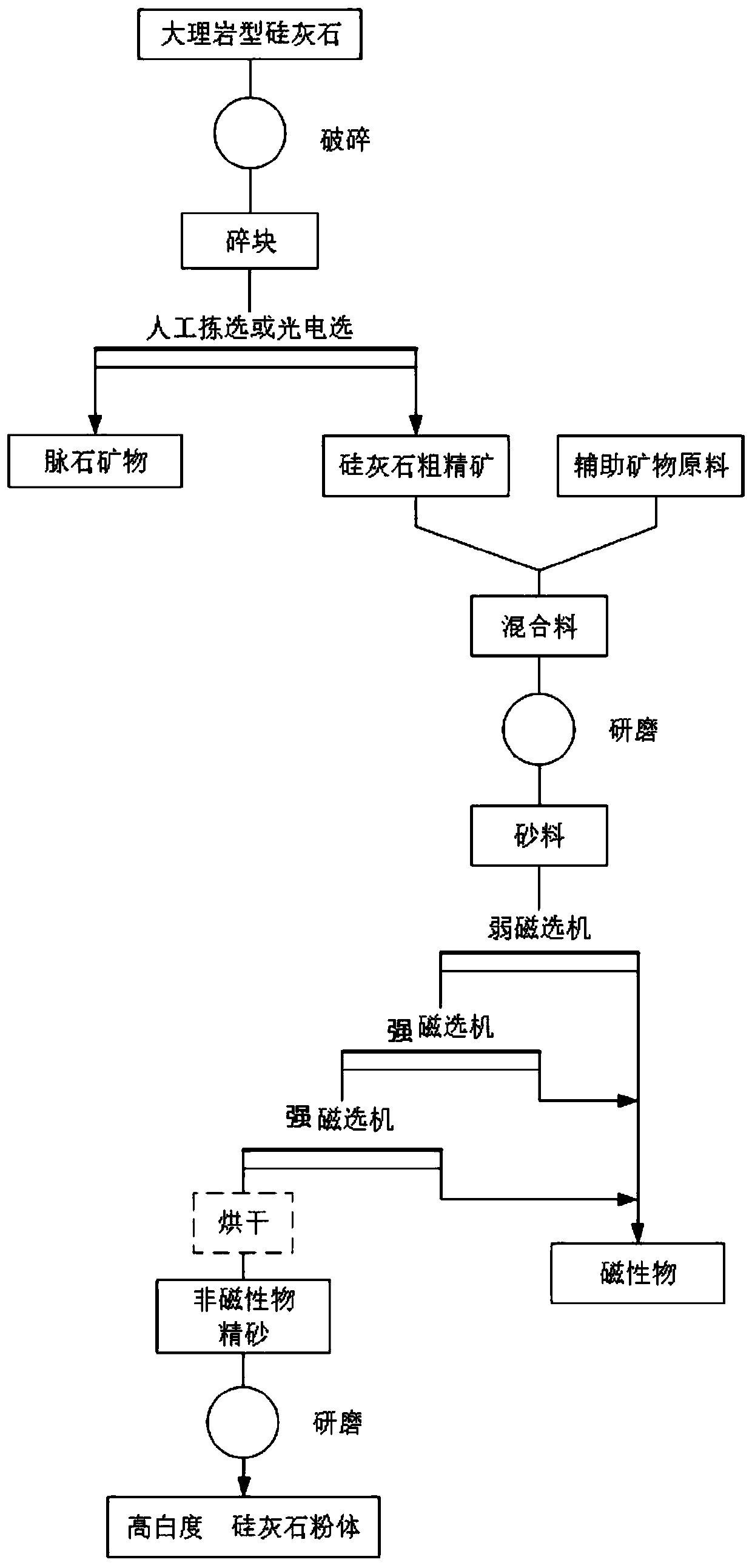

Method used

Image

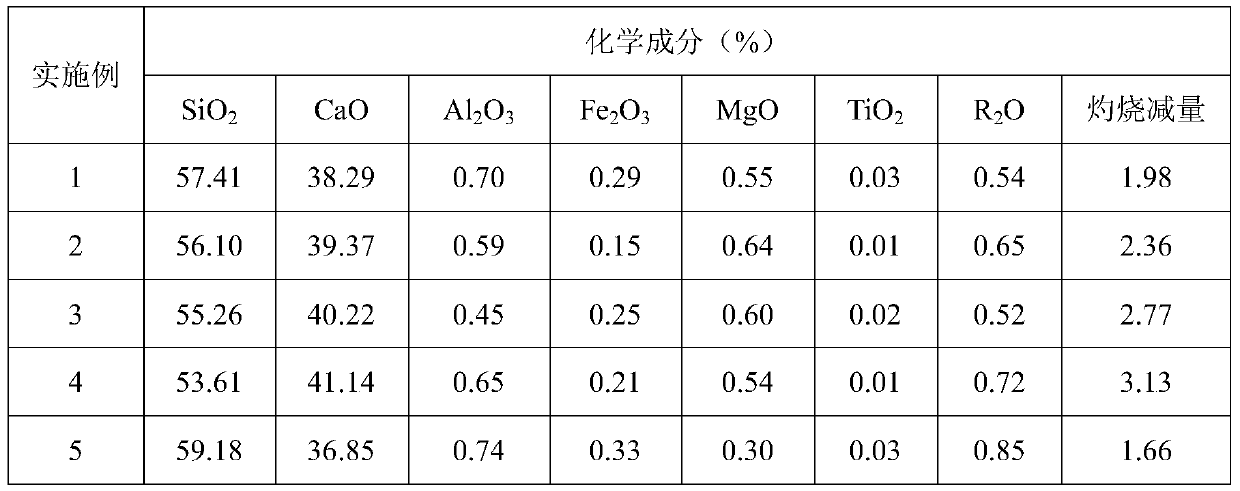

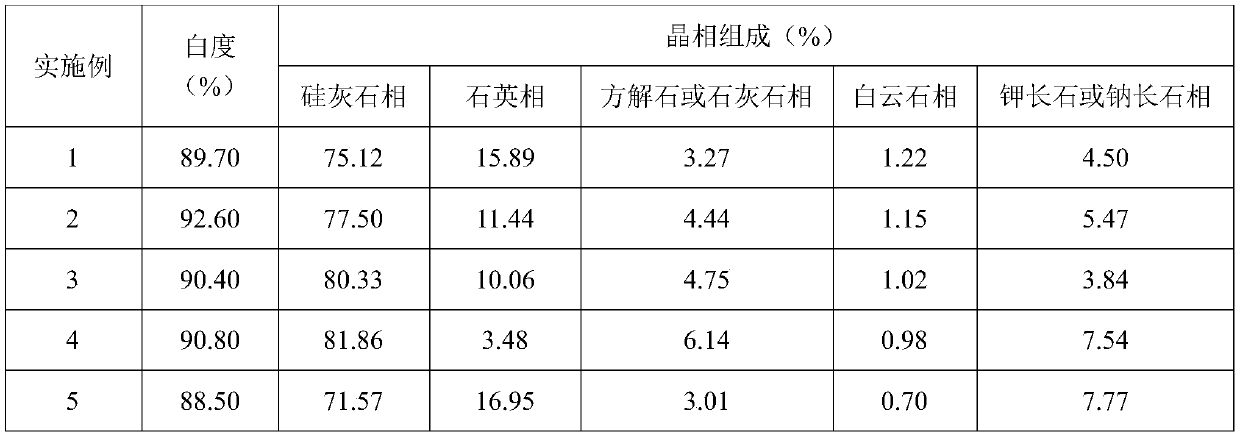

Examples

Embodiment 1

[0030] A preparation method of high whiteness wollastonite powder, comprising the following steps:

[0031] (1) Select marble-type wollastonite ore and crush it into 30mm fragments, and obtain 5-30mm oversize after sieving, wash and dry the oversize, and manually remove calcite, black gangue and sawdust Obtain wollastonite coarse concentrate;

[0032] (2) Selecting 9 parts by weight of quartz and 1 part by weight of dolomite with a clean surface of 5 to 30 mm in particle size and mixing with 90 parts by weight of wollastonite coarse concentrate in step (1) to form a mixture;

[0033] (3) the mixture in step (2) is dropped into Raymond mill dry grinding to 100 orders to obtain sand;

[0034] (4) in step (3), the under-sieve material after the 40 mesh vibrating sieve screening is put into a dry type weak magnetic separator, and the non-magnetic matter of the gained is put into a dry type strong magnetic separator again, get fine sand;

[0035] (5) Put the fine sand in step (4...

Embodiment 2

[0037] A preparation method of high whiteness wollastonite powder, comprising the following steps:

[0038] (1) Select marble-type wollastonite ore and crush it into 20mm fragments, and obtain 5-20mm oversize after sieving. After washing with water, dry the oversize, manually remove calcite and sawdust, and then put it into color separation machine, color sorting removes blue calcite and other dark gangue to obtain wollastonite coarse concentrate;

[0039] (2) choosing particle diameter is that 7 parts by weight of quartz, 5 parts by weight of feldspar, 1 part by weight of dolomite and 88 parts by weight of wollastonite coarse concentrate in the step (1) are mixed evenly with the surface cleanness of 5~20mm, form a mixture;

[0040] (3) Watering the mixture in step (2) to a concentration of 70% is dropped into a ball mill for wet grinding to 60 orders to obtain sand;

[0041] (4) In step (3), the under-sieve material after the 40 mesh vibrating sieve screening with the sand ...

Embodiment 3

[0044] A preparation method of high whiteness wollastonite powder, comprising the following steps:

[0045] (1) Select marble-type wollastonite ore and crush it into 25mm fragments, and obtain 10-25mm oversize after sieving, wash and dry the oversize, and manually remove calcite, black slate and sawdust Obtain wollastonite coarse concentrate;

[0046] (2) Selecting 1 part by weight of dolomite with a clean surface of 10 to 20 mm in particle size and mixing with 99 parts by weight of wollastonite coarse concentrate in step (1) to form a mixture;

[0047] (3) The mixture in the step (2) is dropped into a ball mill for dry grinding to 80 orders to obtain sand;

[0048] (4) After distributing the sand material in step (3) to a concentration of 40%, put the undersize after 40-mesh vibrating sieve screening into a wet-type weak magnetic separator, and then put the non-magnetic material into another set Wet strong magnetic separator to obtain fine sand ore pulp;

[0049] (5) Put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com