Inter-node external circulation low-pressure multi-stage absorption device and process for nitrogen oxide-containing waste gas

An absorption device and external circulation technology, which is applied in the field of low-pressure multi-stage gunpowder smoke absorption devices for inter-node external circulation, can solve the problems of secondary pollution, increased treatment costs, and unexplained nitrogen oxide concentration, so as to eliminate airflow fluctuations and reduce energy consumption. Consumption, guaranteed removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

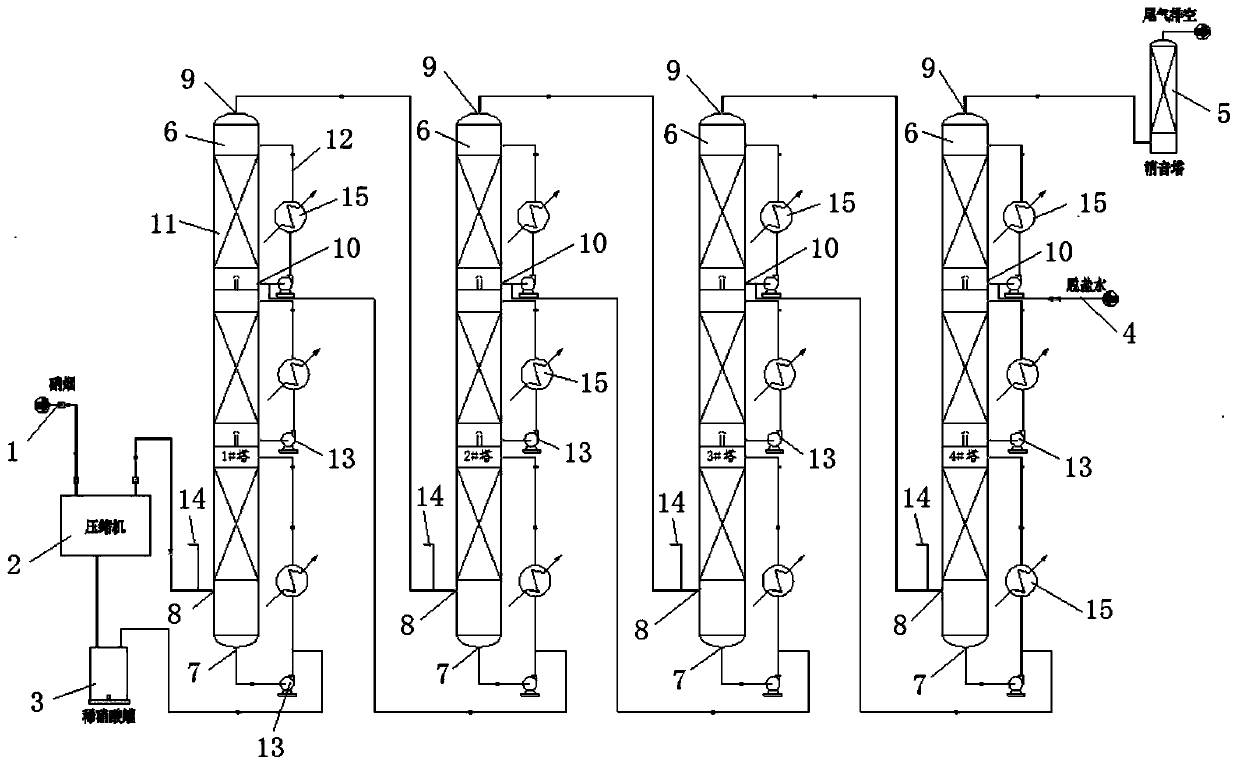

[0034] It can be seen from the accompanying drawings that a low-pressure multi-stage gunpowder smoke absorption device for internode external circulation includes a gunpowder smoke inlet pipe 1, a compressor 2, a liquid storage tank 3, a gunpowder smoke absorption tower assembly, an absorption liquid inlet pipe 4, and a silencer tower 5. The smoke intake pipe 1 is connected to the compressor 2, one end of the compressor 2 is connected to the smoke absorption tower assembly, the other end of the compressor 2 is connected to the liquid storage tank 3, and the smoke smoke absorption tower assembly is connected to the liquid storage tank 3; The top of the gunpowder smoke absorption tower assembly is connected to the silencer tower 5 , and the gunpowder smoke absorption tower assembly is connected to the absorption liquid inlet pipe 4 .

[0035] The gunpowder smoke absorption tower assembly includes at least two gunpowder smoke absorption towers 6, each gunpowder smoke absorption to...

Embodiment 2

[0043] Taking the waste acid concentration and nitrification tail gas absorption treatment device of a certain factory as an example, the composition of the gunpowder smoke at normal temperature and pressure is 10000-20000mg / m 3 (with NO 2 count).

[0044] Smoke absorption: Turn on the smoke compressor 2, and the pressurized smoke enters 1#, 2#, 3#, and 4# smoke absorption towers 6; #, 3#, 2#, 1# Gunpowder Smoke Absorption Tower 6, the gas-liquid two-phase is absorbed in countercurrent circulation in the absorption tower. Control the pressure of the gunpowder smoke absorption system to 0.15MPa; the liquid level of the 6 tanks of the gunpowder smoke absorption tower is 300-450mm; the circulating spray volume of each section of the absorption liquid is 8m 3 / h; 1# tower kettle, tower top temperature ≤ 30 ℃, other tower kettle, tower top temperature ≤ 15 ℃. The 1# smoke absorption tower cooler uses circulating water to remove the reaction heat in the smoke absorption process;...

Embodiment 3

[0049] Taking the waste acid concentration and nitrification tail gas absorption treatment device of a certain factory as an example, the composition of the gunpowder smoke at normal temperature and pressure is 10000-20000mg / m 3 (with NO 2 count).

[0050] Smoke absorption: Turn on the smoke compressor 2, and the pressurized smoke enters 1#, 2#, 3#, and 4# smoke absorption towers 6; #, 3#, 2#, 1# Gunpowder Smoke Absorption Tower 6, the gas-liquid two-phase is absorbed in countercurrent circulation in the absorption tower. Control the pressure of the gunpowder smoke absorption system to 0.2MPa; the liquid level of the 6 tanks of the gunpowder smoke absorption tower is 300-450mm; the circulating spray volume of the absorption liquid in each section is 6m 3 / h; 1# tower kettle, tower top temperature ≤ 30 ℃, other tower kettle, tower top temperature ≤ 20 ℃. The 1# smoke absorption tower cooler uses circulating water to remove the reaction heat in the smoke absorption process; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com