Ammonia desulfurization process and system

A technology of ammonia desulfurization and process, applied in the field of ammonia desulfurization process and system, to achieve the effect of small transformation, short construction period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

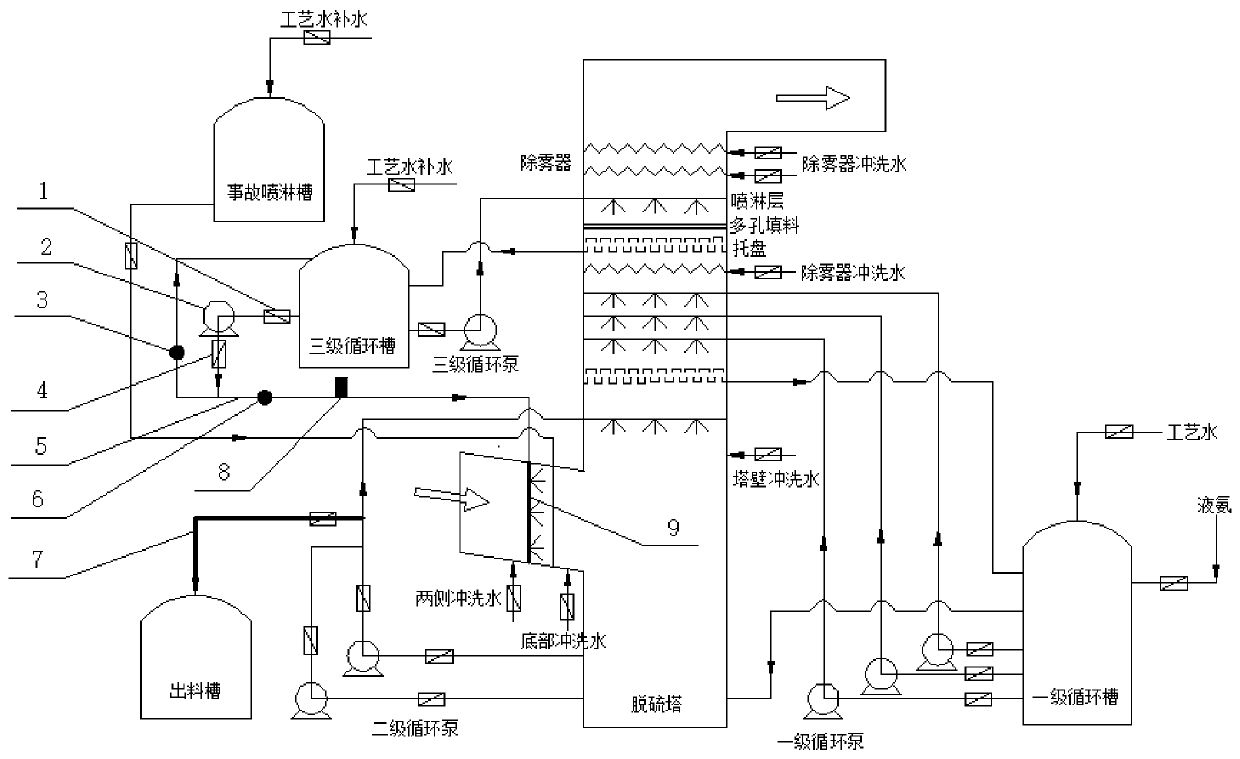

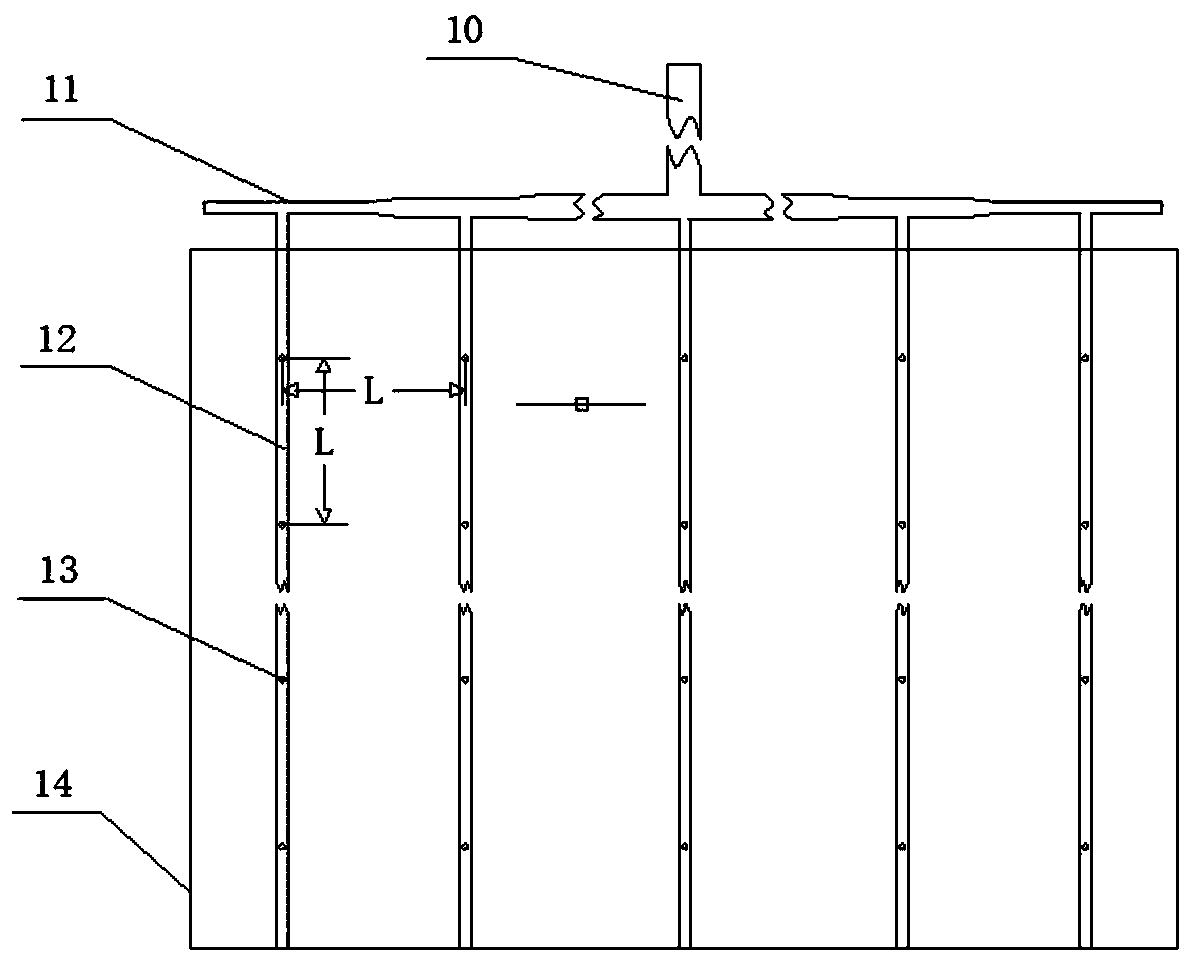

[0041] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

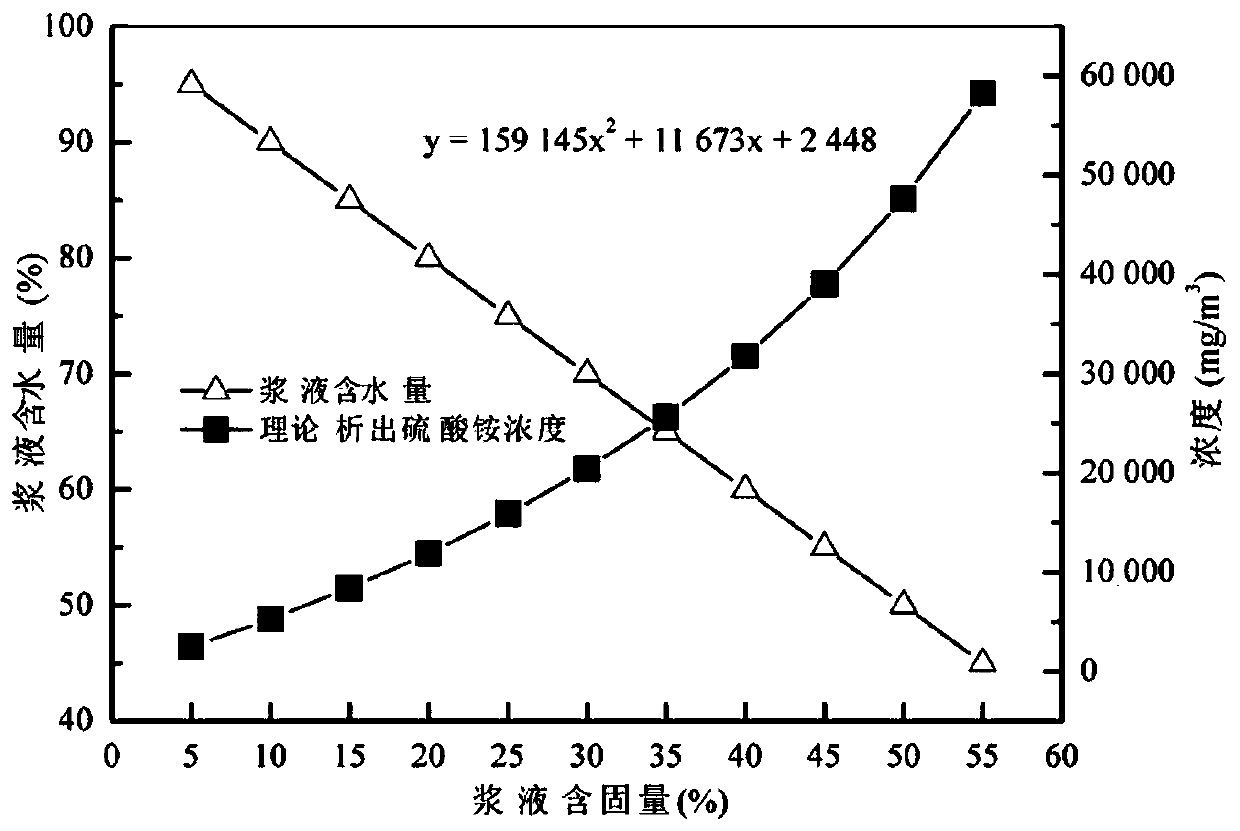

[0042] The most critical idea of the present invention is to arrange a pre-cooling spray system at the entrance area of the absorption tower, use the circulating water of the original system as the spray process water, and calculate the actual spray water required by the evaporation of the flue gas cooling water, To achieve the purpose of water recycling and water conservation.

[0043] The ammonia desulfurization process according to the embodiment of the first aspect of the present invention includes the step of introducing the flue gas into the desulfurization tower and performing desulfurization through the ammonia method, wherein the temperature of the flue gas is pre-cooled and sprayed at the entrance area of the absorption tower in the desulfurizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com