Separation and purification method of jujube polysaccharide with antioxidant effect

An anti-oxidation, separation and purification technology, applied in the field of food deep processing, can solve the problems of low purity and extraction rate, complex components of crude polysaccharides, limited types of polysaccharides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

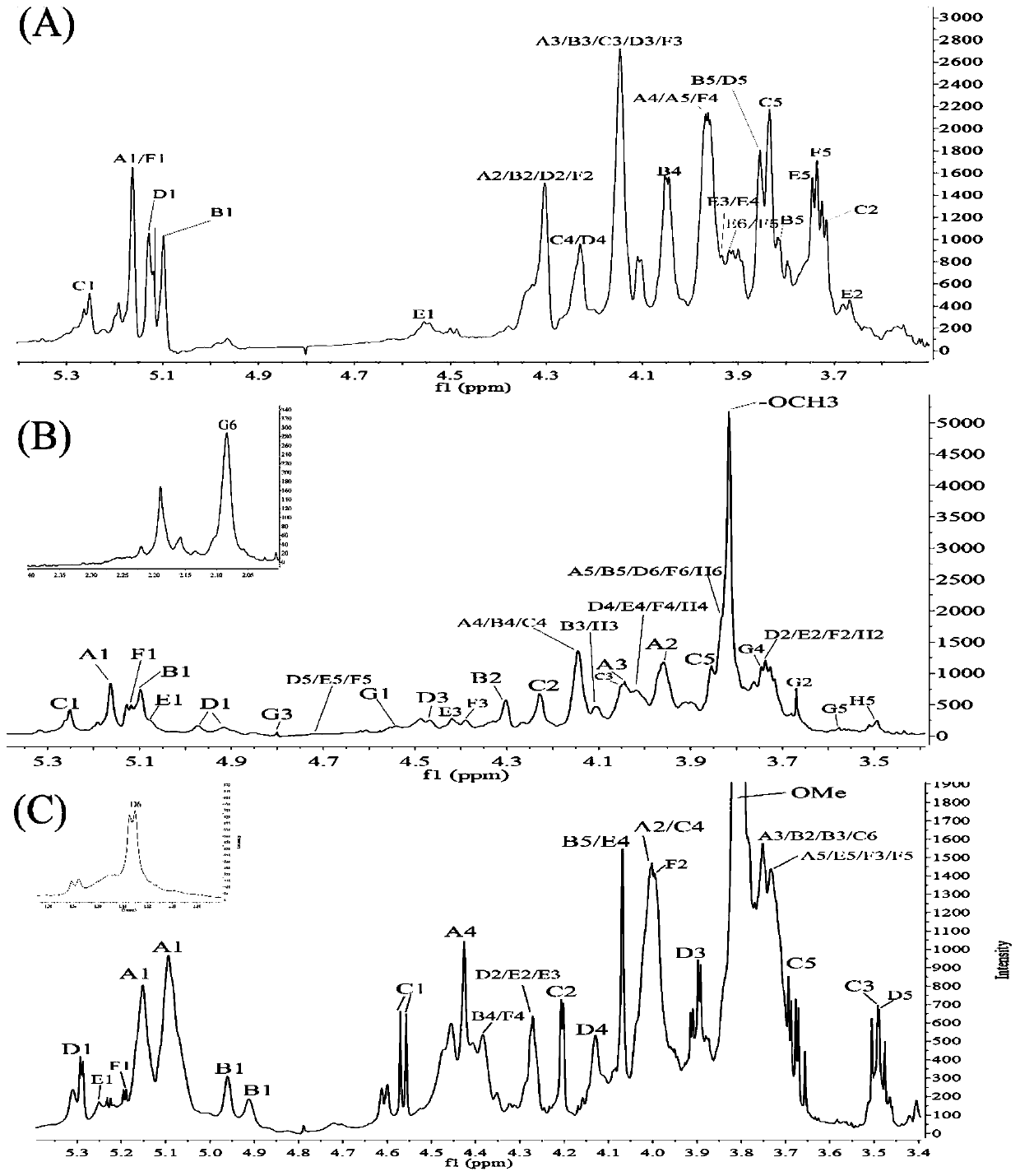

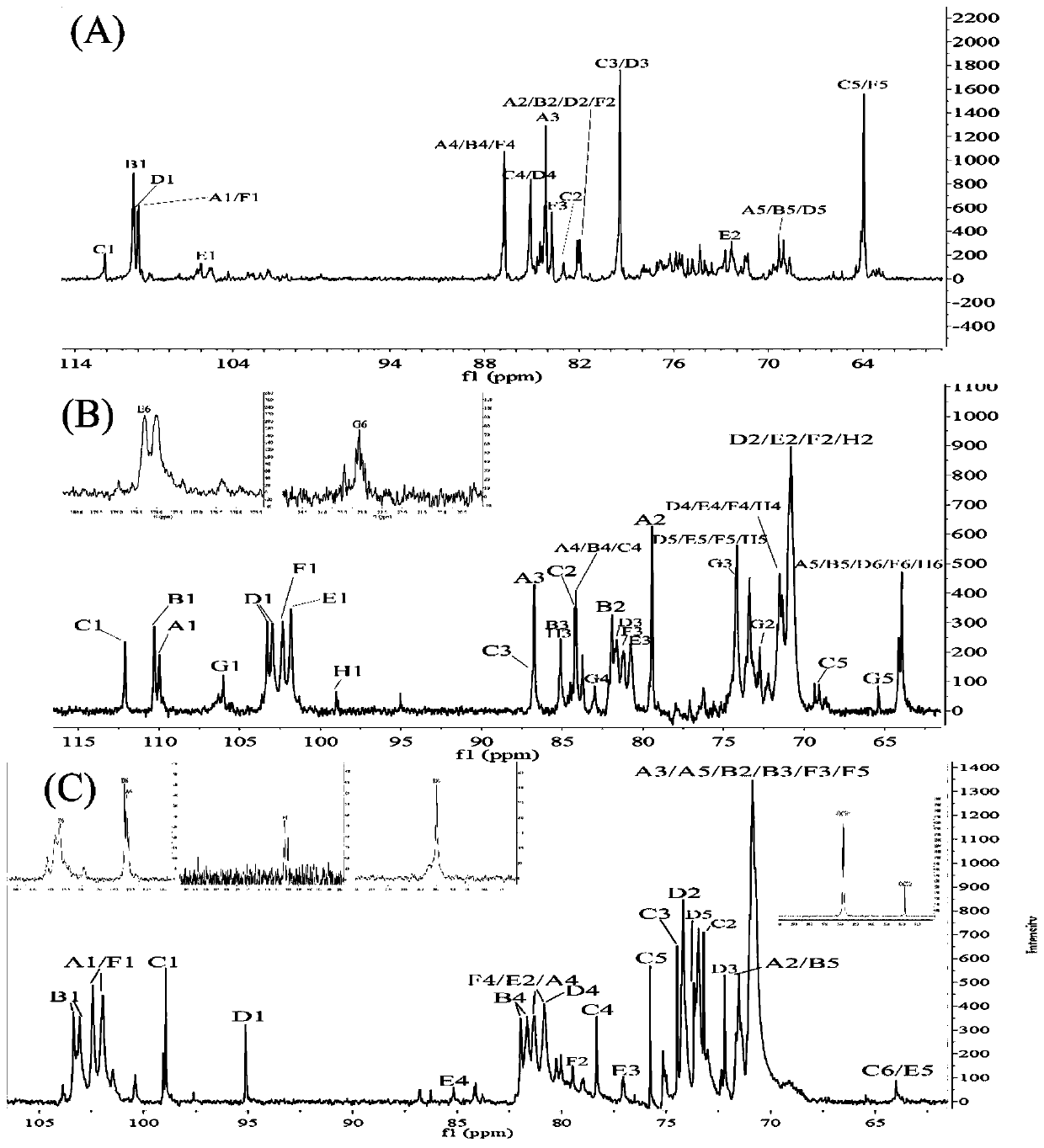

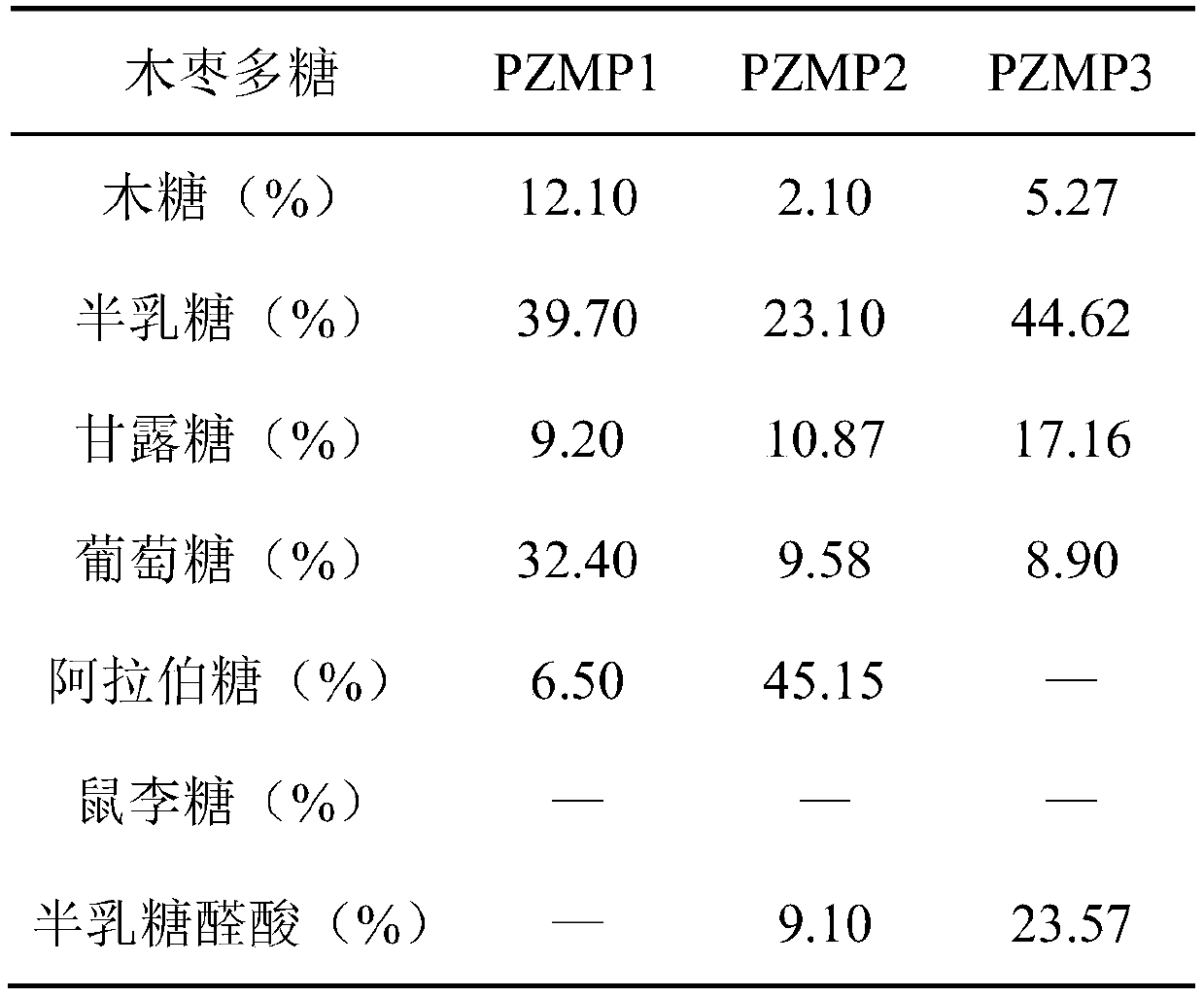

Image

Examples

Embodiment 1

[0032] A preparation method for separation and purification of jujube polysaccharide, the steps are:

[0033] 1. Preparation of jujube polysaccharide:

[0034] (1) Ultrasonic-assisted hot water extraction: select the dried Jiaxian jujube, dry the jujube raw material at 50°C, and after cooling, use a high-speed pulverizer to crush the raw material, pass the crushed raw material through a 100-mesh sieve, and pass the sieve The slag in the upper part is put back into the pulverizer for re-crushing. A certain quality of jujube jujube powder sample was leached in a 70°C water bath for 30 minutes with the aid of ultrasound at a material-to-liquid ratio of 23:1, and the ultrasonic power was 420W. After centrifugal filtration, the obtained supernatant was concentrated to obtain a concentrate.

[0035] (2) Alcohol precipitation: add absolute ethanol to the concentrated solution in step (1) while stirring until the volume fraction of ethanol in the system reaches 85%, stay overnight a...

Embodiment 2

[0041] A preparation method for separation and purification of jujube polysaccharide, the steps are:

[0042] 1. Preparation of jujube polysaccharide:

[0043] (1) Ultrasonic assisted hot water extraction: select the dried Jiaxian jujube, dry the raw material of jujube at 60°C, and after cooling, use a high-speed pulverizer to crush the raw material, pass the crushed raw material through a 100-mesh sieve, and pass the sieve The slag in the upper part is put back into the pulverizer for re-crushing. A certain quality of jujube jujube powder sample was leached in a 60°C water bath for 20 minutes with the aid of ultrasound at a solid-to-liquid ratio of 23:1, and the ultrasonic power was 420W. After centrifugal filtration, the obtained supernatant was concentrated to obtain a concentrate.

[0044] (2) Alcohol precipitation: add absolute ethanol to the concentrated solution in step (1) while stirring until the volume fraction of ethanol in the system reaches 85%, stay overnight a...

Embodiment 3

[0050] A preparation method for separation and purification of jujube polysaccharide, the steps are:

[0051] 1. Preparation of jujube polysaccharide:

[0052] (1) Ultrasonic-assisted hot water extraction: select the dried Jiaxian jujube, dry the jujube raw material at 50°C, and after cooling, use a high-speed pulverizer to crush the raw material, pass the crushed raw material through a 100-mesh sieve, and pass the sieve The slag in the upper part is put back into the pulverizer for re-crushing. A certain quality of jujube jujube powder sample was leached in a 70°C water bath for 30 minutes with the aid of ultrasound at a material-to-liquid ratio of 23:1, and the ultrasonic power was 420W. After centrifugal filtration, the obtained supernatant was concentrated to obtain a concentrate.

[0053] (2) Alcohol precipitation: add absolute ethanol to the concentrated solution in step (1) while stirring until the volume fraction of ethanol in the system reaches 85%, stay overnight a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com