Adhesive for wood and preparation method of same

A technology of adhesives and wood, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of short activation period, unstable product quality, inability to use price reactivity, etc., and achieve activation The effect of long-term and stable bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

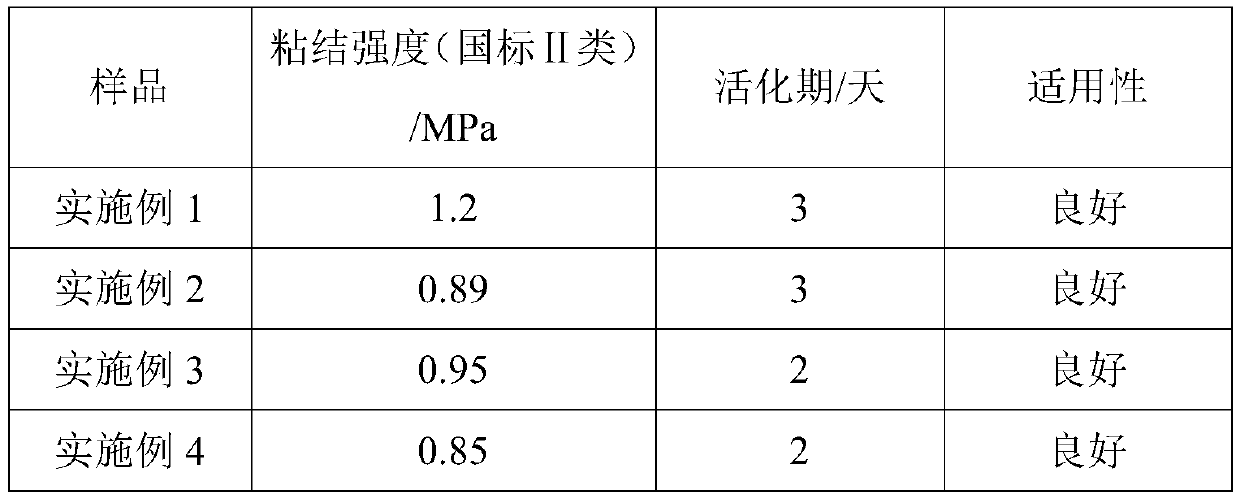

Examples

preparation example Construction

[0015] The preparation method of the wood adhesive of the present invention comprises the following steps: uniformly mixing the adhesive A liquid material with the reinforcing agent powder to obtain a powder-liquid mixture, the reinforcing agent powder being soybean defatted soybean powder, cottonseed protein powder, peanut protein powder, starch, and flour; then mix the powder-liquid mixture with adhesive material B evenly to obtain an adhesive; the adhesive is polyurethane adhesive, soybean protein adhesive One of the agent and starch adhesive.

[0016] The powder-liquid mixture also includes water.

[0017] The adhesive material B is at least one of toluene diisocyanate, xylene diisocyanate and polyamide epichlorohydrin.

[0018] The ratio of the mass of the powder-liquid mixture to the mass of the adhesive is (55-95): (5-45), that is, the ratio is 1.2-19. Preferably, the ratio of the mass of the powder-liquid mixture to the mass of the adhesive material B is 1.6-11.

[...

Embodiment 1

[0026] The preparation method of the adhesive of the present embodiment comprises the following steps:

[0027] 1) 10g of ethylene glycol, 95g of defatted soybean flour and 300g of water (water enters the powder-liquid mixer from the liquid feed port) are mixed uniformly at a stirring rate of 1000rpm to obtain a powder-liquid mixture;

[0028] 2) Mix the obtained powder-liquid mixture with 40 g of toluene diisocyanate evenly at a stirring rate of 300 rpm to obtain the product.

Embodiment 2

[0030] The preparation method of the adhesive of the present embodiment comprises the following steps:

[0031] 1) 10g of glycerol, 70g of cottonseed protein powder, 10g of starch and 300g of water were uniformly mixed at a stirring rate of 2000rpm to obtain a powder-liquid mixture;

[0032] 2) Mix the obtained powder-liquid mixture with 60 g of xylene diisocyanate at a stirring rate of 500 rpm to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com