A compound enzyme and its application in animal protein production

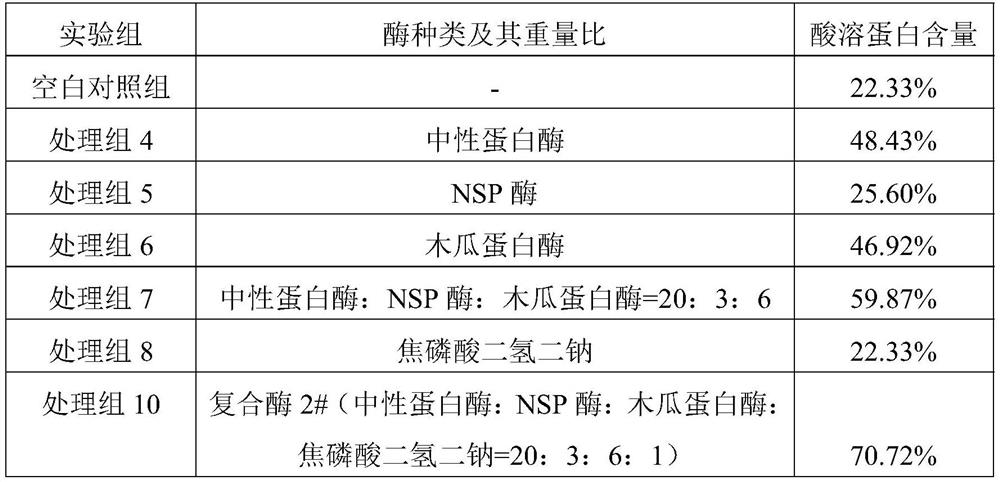

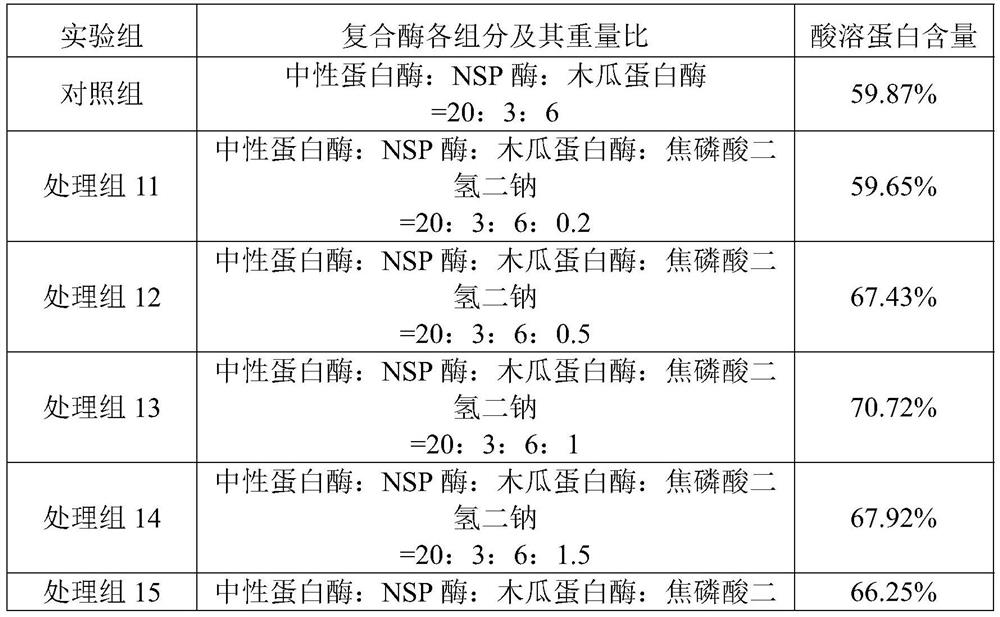

A compound enzyme, animal technology, applied in the direction of enzymes, peptidases, hydrolases, etc., can solve the problems of amino acid damage, no exposure, narrow modification range, etc., and achieve the effect of promoting efficient degradation, quality improvement, and umami increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A complex enzyme, its components and weight ratio are: 24 parts of neutral protease, 5 parts of NSP enzyme, 9 parts of papain and 2 parts of disodium dihydrogen pyrophosphate.

[0024] The components of the compound enzyme were weighed according to the above weights, and mixed uniformly to obtain the compound enzyme of the present invention, which was named as compound enzyme 1#.

Embodiment 2

[0026] A compound enzyme, its components and weight ratio are: 20 parts of neutral protease, 3 parts of NSP enzyme, 6 parts of papain and 1 part of disodium dihydrogen pyrophosphate.

[0027] The preparation method is the same as in Example 1, and the prepared complex enzyme is named as complex enzyme 2#.

Embodiment 3

[0029] A composite enzyme, its components and weight ratio are: 21 parts of neutral protease, 6 parts of NSP enzyme, 4 parts of papain and 3 parts of disodium dihydrogen pyrophosphate.

[0030] The preparation method is the same as in Example 1, and the prepared complex enzyme is named as complex enzyme 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com