Supercritical hydrothermal combustion type steam generator for thermal recovery of heavy oil in ultra-deep well

A technology of steam generator and thermal recovery of heavy oil, which is applied in the direction of steam generation, production fluid, earthwork drilling and production, etc. It can solve the problems of environmental pollution, limited mining depth, high mining cost, etc., and achieve cost reduction, emission reduction, and compact structure small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

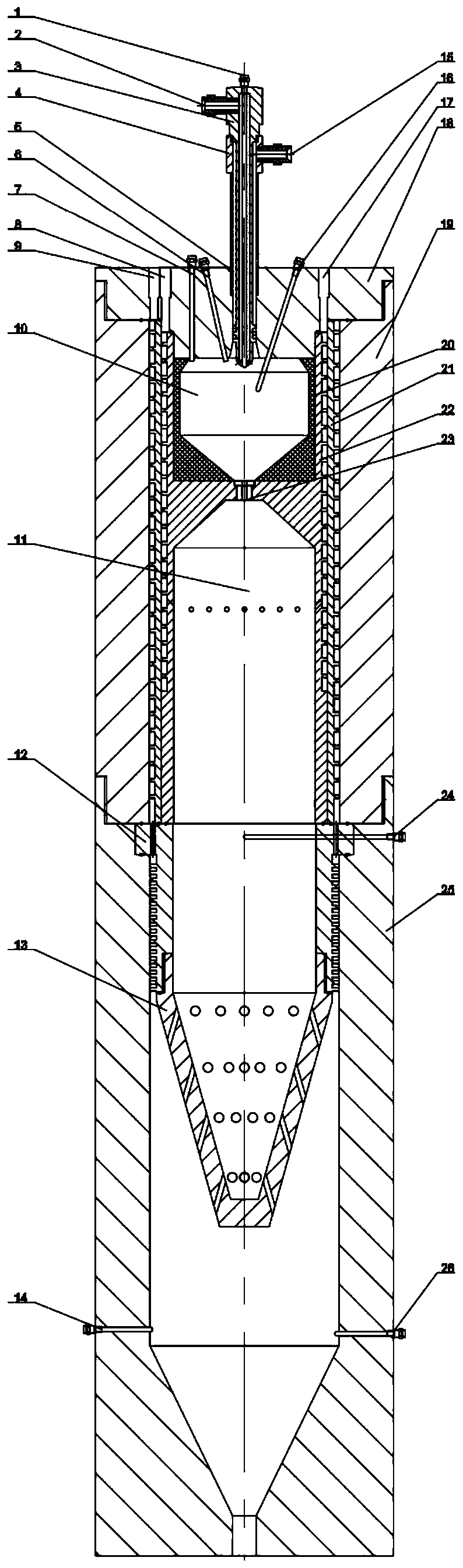

[0025] Such as figure 1 As shown, a supercritical hydrothermal combustion steam generator for thermal recovery of heavy oil in an ultra-deep well, its main part includes a generator head 18, a generator upper part 19 and a generator lower part 25 that are sequentially connected and assembled, wherein , the interior of the upper part 19 of the generator is the main reaction zone, which can be formed by communicating with the primary combustion chamber 10 above and the secondary combustion chamber 11 below through the throat assembly 23. The primary combustion chamber 10 can be surrounded by refractory components 20, and the refractory components 20 Materials include but are not limited to one or more commercially available inorganic metal or non-metal materials such as silicon carbide, cermet, and silicon nitride. Generator bottom 25 can be prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com