Isotactic polylactic acid porous microspheres and preparation method thereof

A technology of porous microspheres and polylactic acid, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problem that polylactic acid microspheres cannot have both stereocrystalline and porous structures, and achieve easy movement and heat resistance Good, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A full-stereopolylactic acid porous microsphere, the preparation method of which is as follows: firstly, the weight-average molecular weights with a mass ratio of 1:1 are both 0.5*10 4 g / mol of PLLA and PDLA were dissolved in DMF solvent at a temperature of 50°C to obtain a polylactic acid solution, wherein the sum of the weights of PLLA and PDLA per 100 mL of the polylactic acid solution was 1 g, and then the polylactic acid solution was heated at 10°C / min. The rate was reduced to a temperature of 5 °C to obtain all-stereopolylactic acid porous microspheres.

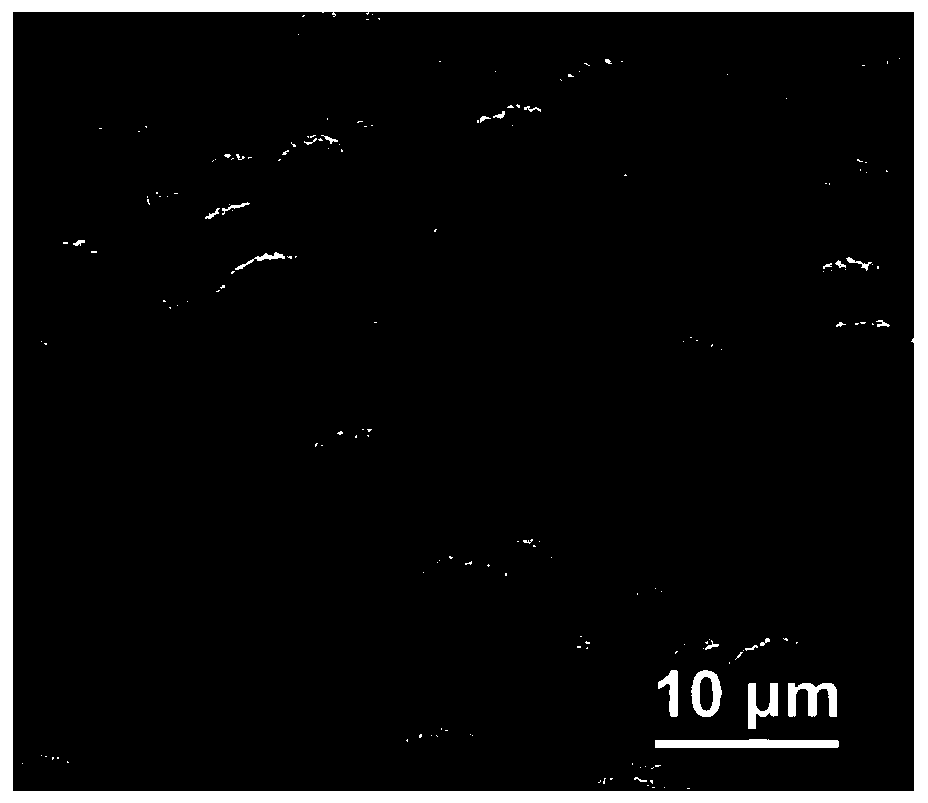

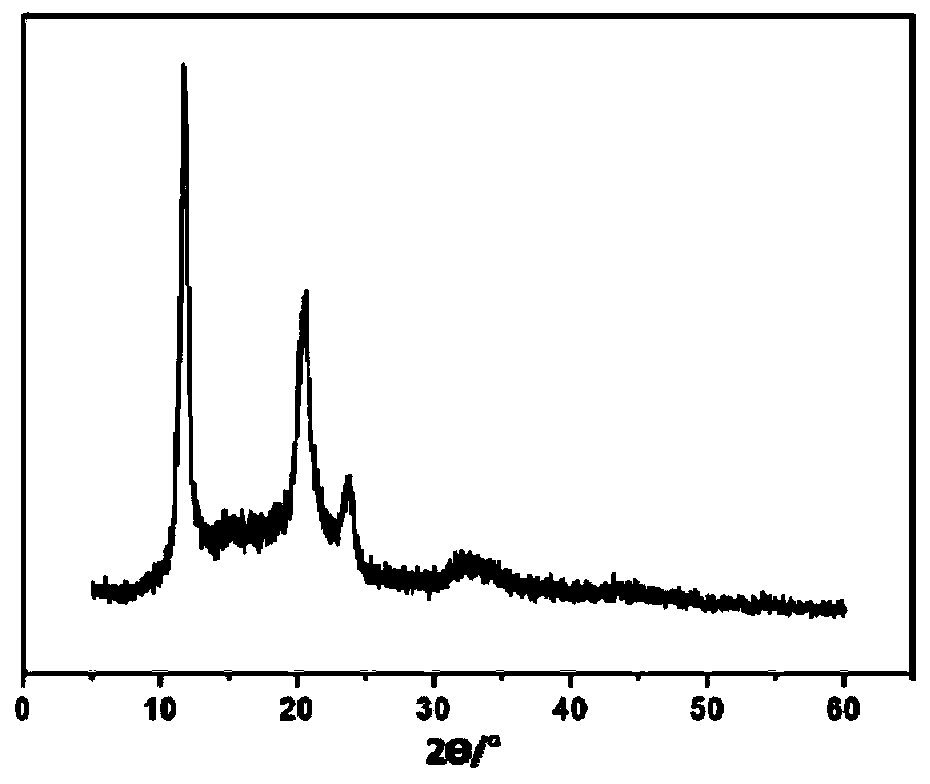

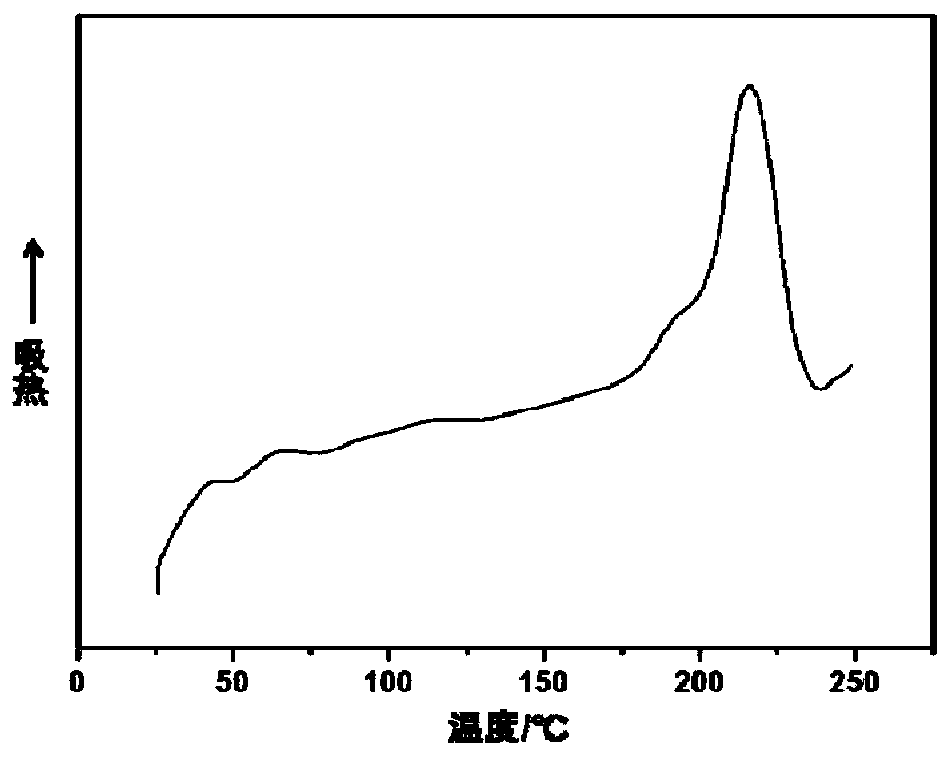

[0031] The finally obtained all-stereopolylactic acid porous microspheres are polylactic acid microspheres with all-stereoscopic crystal morphology and porous structure, which were characterized by SEM, XRD and DSC respectively. The results are as follows: figure 1 , figure 2 and image 3 As shown, the average particle size of all-stereopolylactic acid porous microspheres is 5 μm, the porosity is 10%, the heat...

Embodiment 2

[0039] An all-stereopolylactic acid porous microsphere, the preparation method of which is as follows: firstly, the weight-average molecular weights with a mass ratio of 1:1 are respectively 0.5*10 4 g / mol and 10.8*10 4 g / mol of PLLA and PDLA were dissolved in DMF solvent at a temperature of 65°C to obtain a polylactic acid solution, wherein the sum of the weights of PLLA and PDLA per 100 mL of the polylactic acid solution was 5 g, and then the polylactic acid solution was heated at 8°C / min. The rate of reducing the temperature to 0 °C to obtain all-stereopolylactic acid porous microspheres, followed by post-processing, the post-processing process is: using water to extract the DMF solvent in the all-stereopolylactic acid porous microspheres, washing and drying .

[0040] The finally prepared all-stereopolylactic acid porous microspheres are polylactic acid microspheres with all-stereoscopic crystal morphology and porous structure. The heat distortion temperature was 109 °C ...

Embodiment 3

[0042] A full-stereopolylactic acid porous microsphere, the preparation method of which is as follows: firstly, the weight-average molecular weights with a mass ratio of 1:1 are respectively 6.6*10 4 g / mol and 12.7*10 4 g / mol of PLLA and PDLA were dissolved in DMSO solvent at a temperature of 100 °C to obtain a polylactic acid solution, wherein the sum of the weights of PLLA and PDLA per 100 mL of polylactic acid solution was 12 g, and then the polylactic acid solution was heated to 4.5 °C / The rate of min is lowered to 20 °C to obtain all-stereopolylactic acid porous microspheres, which are then subjected to post-treatment. The post-treatment process is as follows: methanol is used to extract the DMSO solvent in the all-stereopolylactic acid porous microspheres, and washing and dry.

[0043] The finally prepared all-stereopolylactic acid porous microspheres are polylactic acid microspheres with a full-stereoscopic crystal form and a porous structure. The heat distortion tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com