Ink-free laser color printing method based on phase change material

A technology of color printing and phase change materials, applied in the direction of temperature recording method, etc., can solve the problems of complex structural design and complex film structure, etc., and achieve the effect of low cost, rich colors, and colorful printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides an ink-free laser color printing method based on phase change materials, the steps of which include:

[0033] 1) Coating a GeTe film 2 with a thickness of 10 nm on the quartz glass 1 by magnetron sputtering;

[0034] 2) Continue to deposit a layer of 20nm thick ZnS-SiO on the GeTe film 2 2 Film 3, to obtain a coating sample;

[0035] 3) A laser printing system is used to print the above coating samples in color, the wavelength of the laser beam 4 used is 405nm; the numerical aperture of the lens 5 is 0.45; the writing speed is 1m / s.

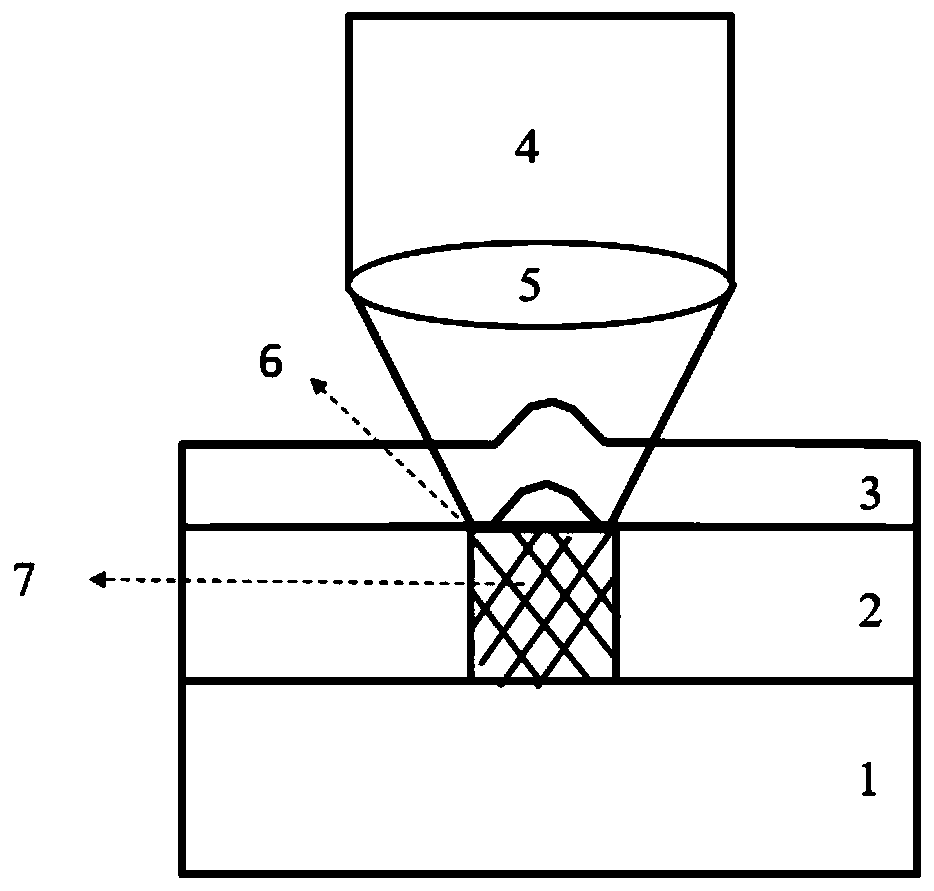

[0036] Schematic diagram of laser color printing such as figure 1 As shown, in this embodiment, a GeTe film is used as the phase change layer with a thickness of 10 nm, which is plated on the upper surface of quartz glass and on the lower surface of the dielectric film.

[0037] When the focused laser beam spot 6 is radiated onto the coated sample, the sample absorbs the laser energy and is heated, and then the ...

Embodiment 2~4

[0039] The printing steps of Examples 2-4 are the same as those of Example 1, and the parameters and printing parameters of the coating samples are shown in the table below.

[0040]

[0041]

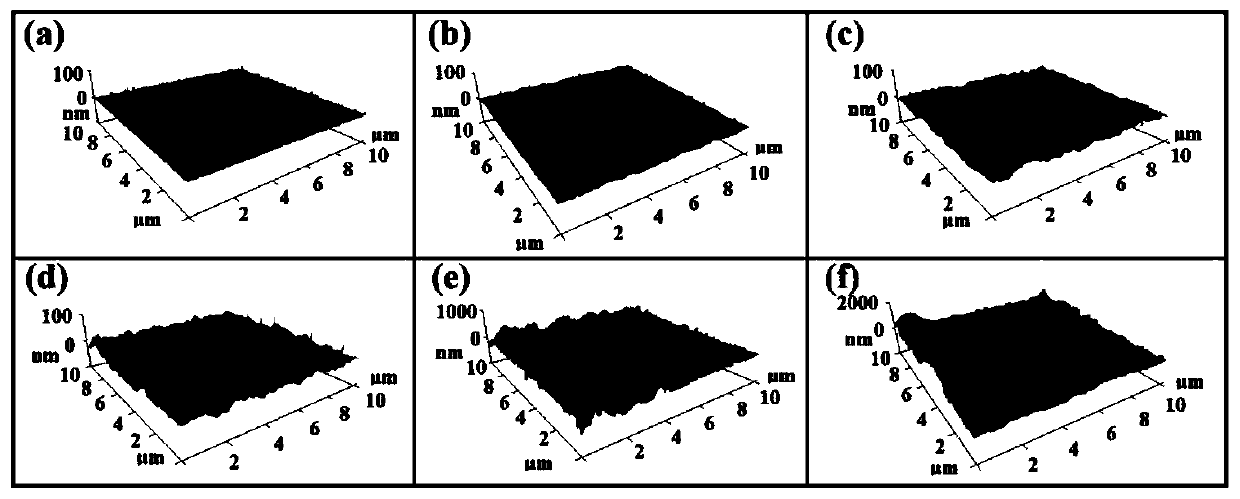

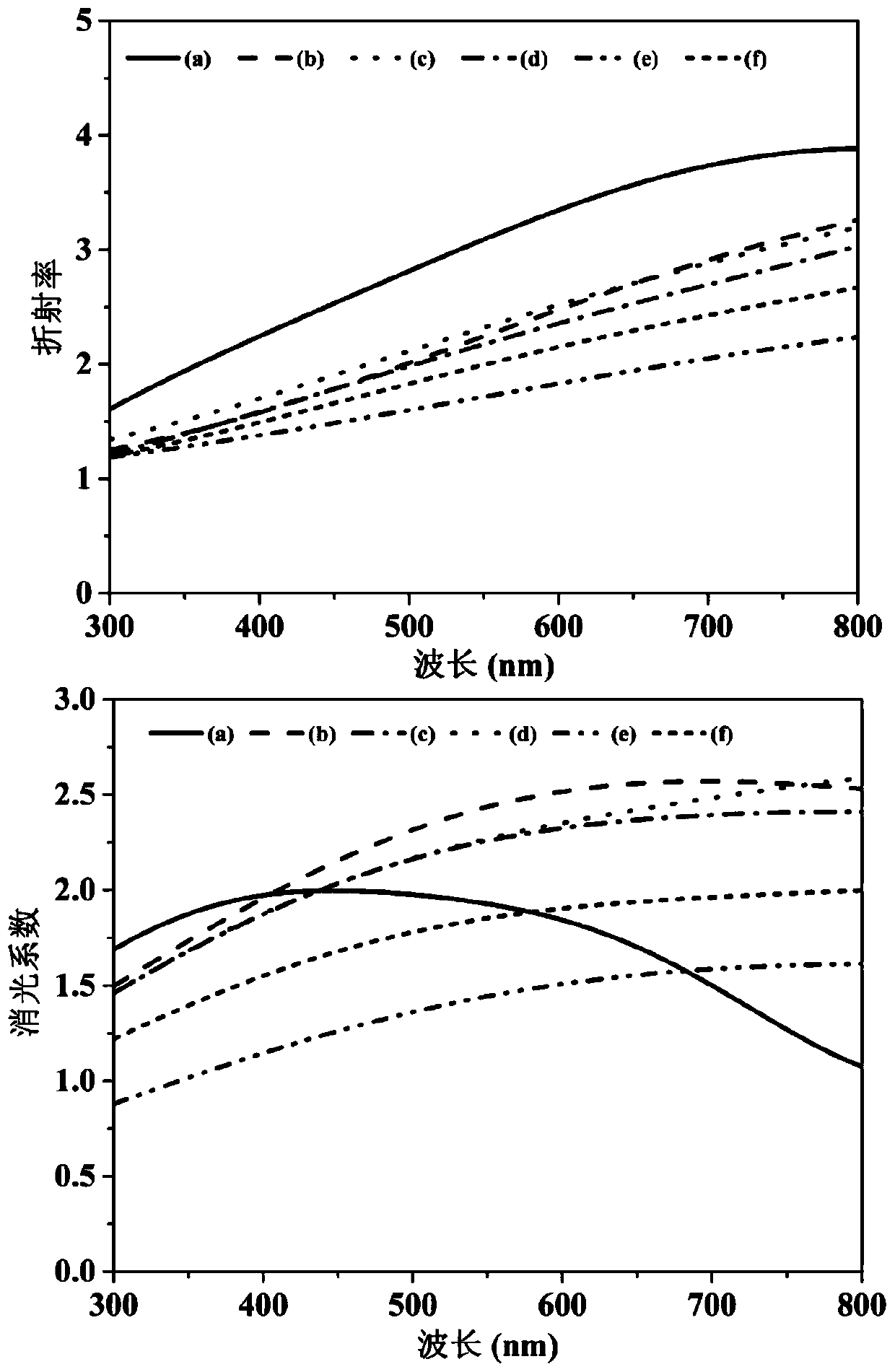

[0042] figure 2 and image 3 It shows that Ge 2 Sb 2 Te 5 Changes of surface microstructure and optical constants of phase change thin film samples. It can be seen from the figure that under the action of laser, Ge 2 Sb 2 Te 5 Various microstructures including bulges appeared on the surface of the phase change film sample, and the optical constants also changed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com