A kind of preparation method of super-hydrophobic sheet film

A technology of horizontal plate and flat film, which is applied in the field of preparation of super-hydrophobic horizontal plate film, which can solve the problems of falling off, complicated operation steps and high cost, and achieve the effects of avoiding falling off, excellent chemical resistance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

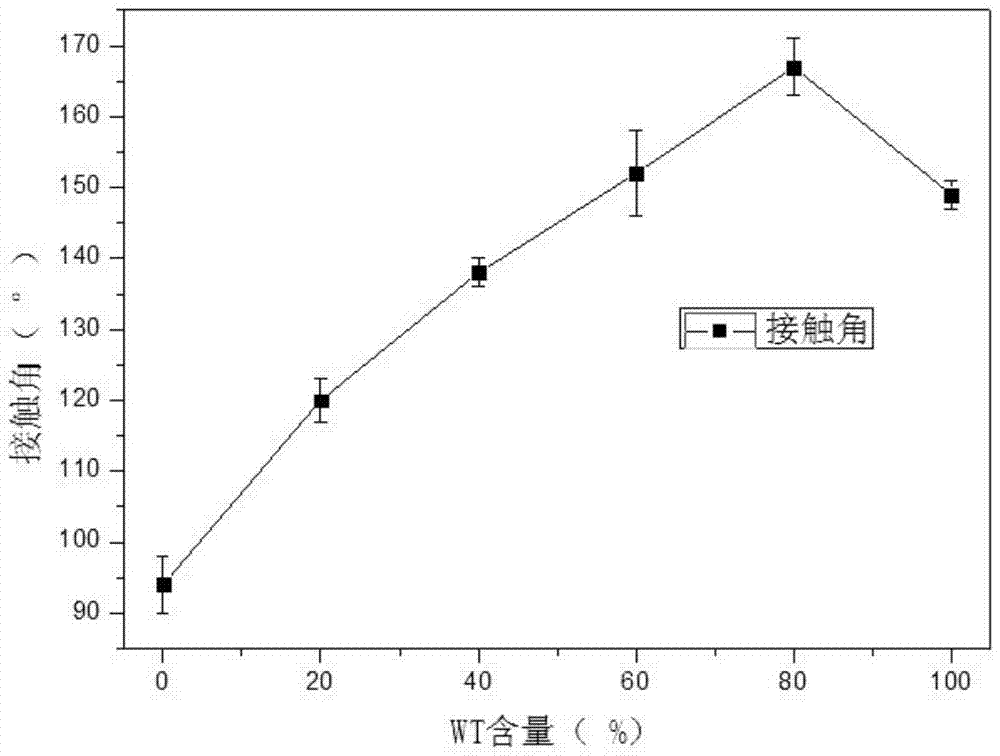

[0042] A method for preparing a super-hydrophobic horizontal plate film, using a polyolefin flat film as a base film, first carrying out membrane hydroxylation treatment on the polyolefin flat base film, and then using silane monomers to carry out silane treatment on the surface of the polyolefin flat base film silanization reaction, constructing a silicone micro- or nano-structured surface on the polyolefin flat base film, by adjusting the water content of the silanization reaction system, controlling the polymerization direction of the silane monomer on the surface of the polyolefin flat base film, and obtaining a super-hydrophobic flat film .

[0043]Based on the research of super-hydrophobic intelligent infiltration of solid surface, the present invention innovatively proposes silanization reaction on the surface of polyolefin flat film from two aspects of surface chemical composition and surface microstructure, and utilizes silanization reaction on the surface of flat base...

Embodiment 1

[0077] (1) Rectify the toluene dried by molecular sieves, take 100 mL of 110°C fraction and store it dry, and use it as anhydrous toluene. It is the saturated toluene solution of solute, then 0.001g methyltrichlorosilane monomer is dissolved in the saturated toluene solution taking water as solute, and the saturated toluene solution taking water as solute is prepared as solvent, and methyltrichlorosilane monomer is Solute, a silane solution with a concentration of 10mg / L, sealed for subsequent use;

[0078] (2) take the polypropylene flat film as the base film, after washing and drying the polypropylene flat film several times, in the newly prepared Piranha solution (H 2 SO 4 :30%H 2 o 2 =7:3) at 50°C for 1 hour to carry out the hydroxylation reaction, then rinse with a large amount of deionized water, and dry for later use;

[0079] (3) Put the hydroxylated polypropylene flat base film into the silane solution prepared in step (1), seal it for silanization reaction for 5 ...

Embodiment 2

[0084] (1) Carry out rectification of toluene, take 100mL of 110°C distillate, mix it with deionized water, let it stand for 2 days after shaking, take the supernatant to obtain a saturated toluene solution with water as the solute, and then add 1g of n-octyltri Dissolve chlorosilane monomer in saturated toluene solution with water as solute, prepare saturated toluene solution with water as solute as solvent, n-octyltrichlorosilane monomer as solute, and a silane solution with a concentration of 10g / L, and seal it for future use .

[0085](2) Taking the polytetrafluoroethylene film flat plate as the base film, after washing and drying the polytetrafluoroethylene flat plate base film several times, in the newly prepared Piranha solution (H 2 SO 4 :30%H 2 o 2 =7:3) at 80°C for 5 hours to carry out the hydroxylation reaction, then rinsed with a large amount of deionized water, and dried for later use;

[0086] (3) Put the polytetrafluoroethylene plate base film after hydroxyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com