Poly-3, 4-ethylenedioxythiophene modified film, preparation method and application thereof

A technology of ethylenedioxythiophene and polyvinylidene fluoride, which is applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve problems such as poor polymerization effect and uneven coating of oxidant, and achieve Ensure the effect and ensure the uniformity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

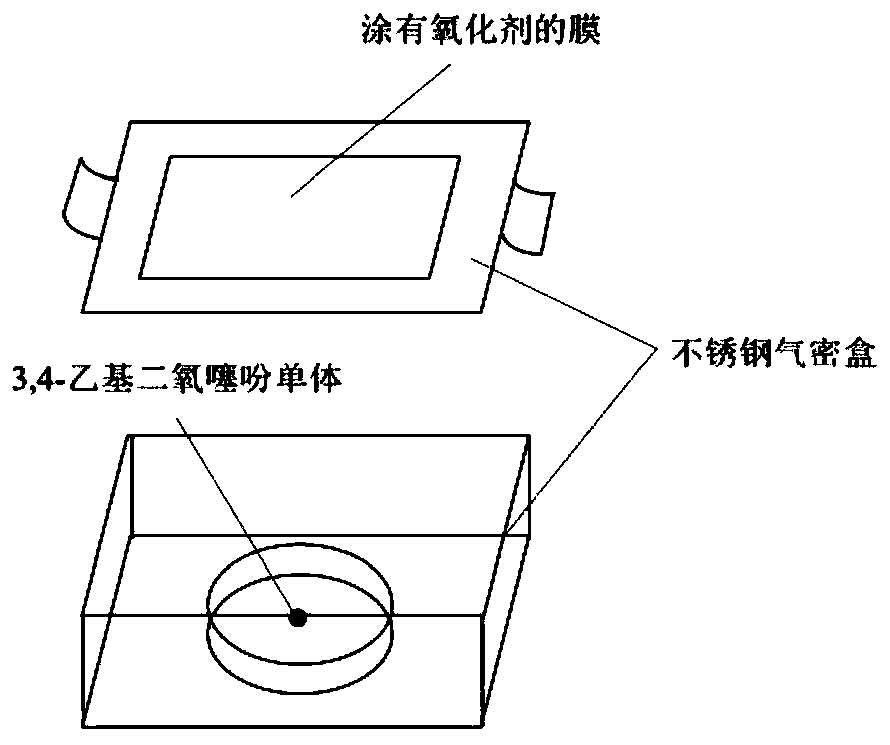

[0034] as attached figure 1 As shown, the invention provides a kind of preparation method of poly-3,4-ethylenedioxythiophene modified film, comprising the following steps:

[0035] Step 1. Prepare a polyvinylidene fluoride base film on the support material; specifically, the following steps are included:

[0036] Step 11, dissolving polyvinylpyrrolidone and polyvinylidene fluoride in N, N-dimethylacetamide in turn, stirring until the air bubbles are eliminated, and obtaining a casting solution; the mass ratio of polyvinylpyrrolidone and polyvinylidene fluoride is (1- 2): 5; the stirring rate is 200~300r / min, and the stirring time is 24-36h;

[0037] Step 12, use a 200-300 μm film scraper to scrape the casting solution obtained in step 1 on the non-woven fabric, and the non-woven fabric is fixed on the surface of the flat substrate; then apply the casting solution The non-woven fabric is soaked in deionized water at room temperature until the casting liquid is solidified to o...

Embodiment 1

[0044] The invention provides a poly-3,4-ethylenedioxythiophene modified film, comprising the following steps:

[0045] Step 1, casting solution preparation

[0046] At room temperature, dissolve 6g of polyvinylpyrrolidone and 15g of polyvinylidene fluoride in 100mL of N,N-dimethylacetamide, stir until the bubbles are eliminated, and obtain a casting solution; wherein, the stirring rate is 300r / min, the stirring time is 24h;

[0047] Step 2. Select a clean non-woven fabric with a size of 16cm×18cm as the support material for the polyvinylidene fluoride substrate, and fix the non-woven fabric on a smooth and flat glass sheet; Scrape the surface of the cloth; then soak the non-woven fabric coated with the casting solution in deionized water at room temperature until the casting solution is solidified, and then wash it with deionized water to obtain a polyvinylidene fluoride base film;

[0048] Step 3, preparation of oxidant solution

[0049] 5g of FeCl 3 ·6H 2 O was dissol...

Embodiment 2

[0055] The invention provides a poly-3,4-ethylenedioxythiophene modified film, comprising the following steps:

[0056] Step 1, casting solution preparation

[0057] At room temperature, dissolve 6g of polyvinylpyrrolidone and 15g of polyvinylidene fluoride in 100mL of N,N-dimethylacetamide, stir until the bubbles are eliminated, and obtain a casting solution; wherein, the stirring rate is 200r / min, the stirring time is 36h;

[0058] Step 2. Select a clean non-woven fabric with a size of 16cm×18cm as the support material for the polyvinylidene fluoride substrate, and fix the non-woven fabric on a smooth and flat glass sheet; Scrape the surface of the cloth; then soak the non-woven fabric coated with the casting solution in deionized water at room temperature until the casting solution is solidified, and then wash it with deionized water to obtain a polyvinylidene fluoride base film;

[0059] Step 3, preparation of oxidant solution

[0060] 20g of FeCl 3 ·6H 2 O was disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com