Deplating method for metal plating layer on surface of waste ABS electroplated part

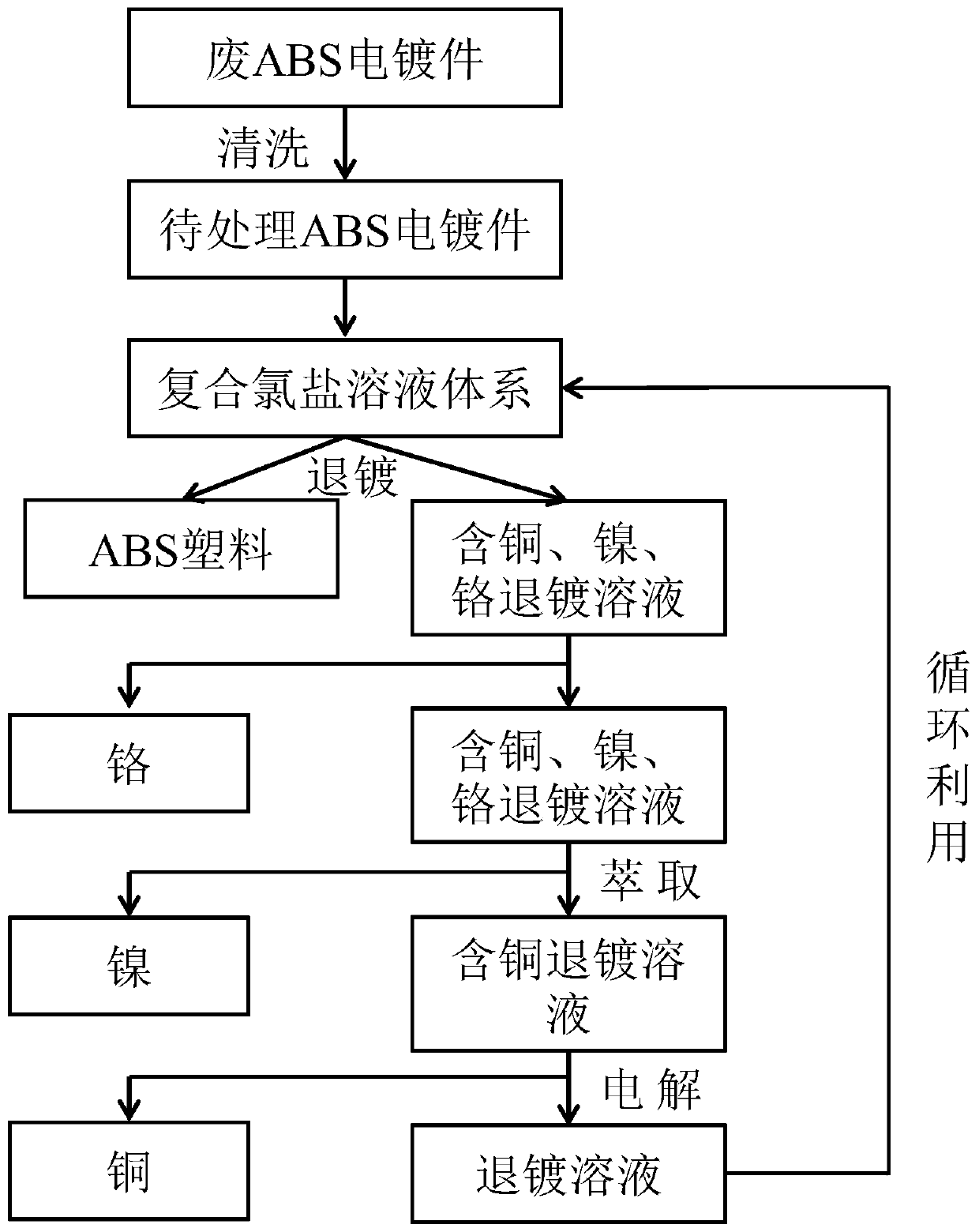

A technology for surface metal and electroplating parts, which is applied in the field of resource recycling of waste ABS electroplating parts, to achieve the effect of improving grades, reducing damage, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Wash the waste ABS electroplating parts with water, ethanol and acetone in sequence to obtain the cleaned ABS electroplating parts; place 4g of the cleaned ABS electroplating parts in the compound chloride salt solution system according to the liquid-solid volume mass ratio of 7ml / g, and put 1 A stirring bar with a diameter of 7 mm was used, and then reacted at 40 °C and 500 rpm for 30 min; where FeCl 3 The mass concentration of the solution is 7%, CuCl 2 The mass concentration of the solution is 10%, AlCl 3 The mass concentration of the solution is 8%, NH 4 The molar concentration of the Cl solution was 0.5 mol / L; after the reaction, the samples were washed, dried, and weighed. Then it is completely stripped, and after the reaction is finished, the stripped sample is taken out from the stripping solution, cleaned, dried, weighed, and then the stripping rate is calculated according to the two stripping results.

[0027] For the deplating solution containing copper-ni...

Embodiment 2

[0030] Wash the waste ABS electroplated parts in sequence with water, ethanol and acetone to obtain the cleaned ABS electroplated parts; put 4g of the cleaned ABS electroplated parts in the compound chloride salt solution system according to the liquid-solid volume mass ratio of 10ml / g, and put 1 A stirring bar with a diameter of 7 mm was used to react for 45 min at a temperature of 50 °C and a rotation speed of 500 rpm; where FeCl 3 The mass concentration of the solution is 10%, CuCl 2 The mass concentration of the solution is 15%, AlCl 3 The mass concentration of the solution is 8%, NH 4 The molar concentration of the Cl solution was 1.0 mol / L; after the reaction, the samples were washed, dried, and weighed. Then it is completely stripped, and after the reaction is finished, the stripped sample is taken out from the stripping solution, cleaned, dried, weighed, and then the stripping rate is calculated according to the two stripping results.

[0031] For the deplating solu...

Embodiment 3

[0034] Wash the waste ABS electroplated parts in sequence with water, ethanol and acetone to obtain the cleaned ABS electroplated parts; put 4g of the cleaned ABS electroplated parts in the compound chloride salt solution system according to the liquid-solid volume mass ratio of 10ml / g, and put 1 A stirring bar with a diameter of 7 mm was used to react for 60 min at a temperature of 50 °C and a rotation speed of 500 rpm; where FeCl 3 The mass concentration of the solution is 8%, CuCl 2 The mass concentration of the solution is 10%, AlCl 3 The mass concentration of the solution is 10%, NH 4 The molar concentration of the Cl solution was 1.0 mol / L; after the reaction, the samples were washed, dried, and weighed. Then it is completely stripped, and after the reaction is finished, the stripped sample is taken out from the stripping solution, cleaned, dried, weighed, and then the stripping rate is calculated according to the two stripping results.

[0035] For the deplating solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com