A kind of composite fluorescent film and its preparation method and the application of laser display

A compound fluorescent and thin-film technology, applied in the field of optical materials, can solve the problems of increased cost and high price of multi-emission feedback systems, achieve excellent thermal stability and chemical stability, and promote the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

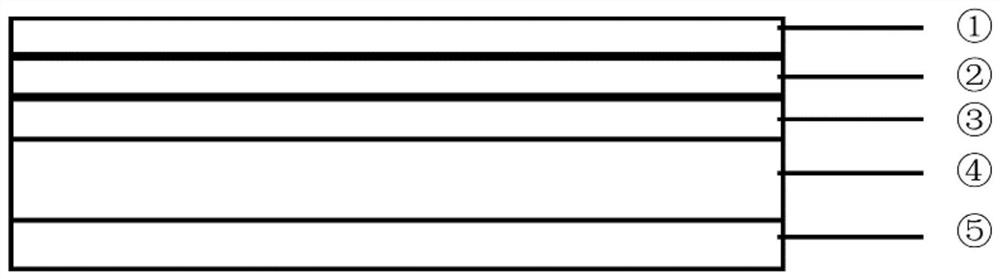

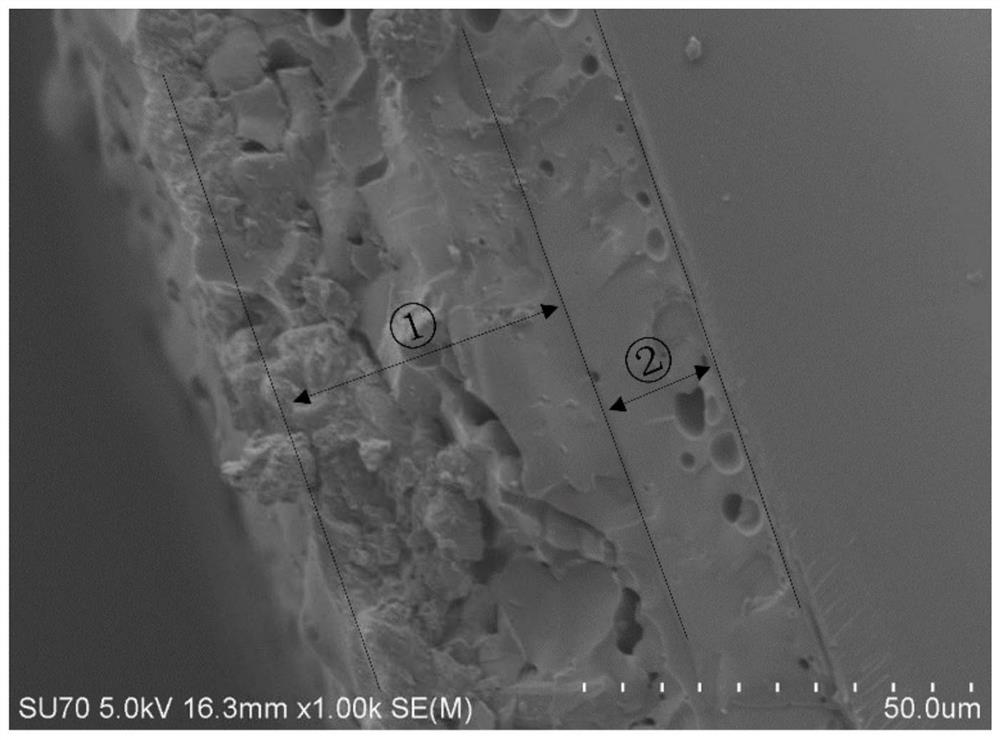

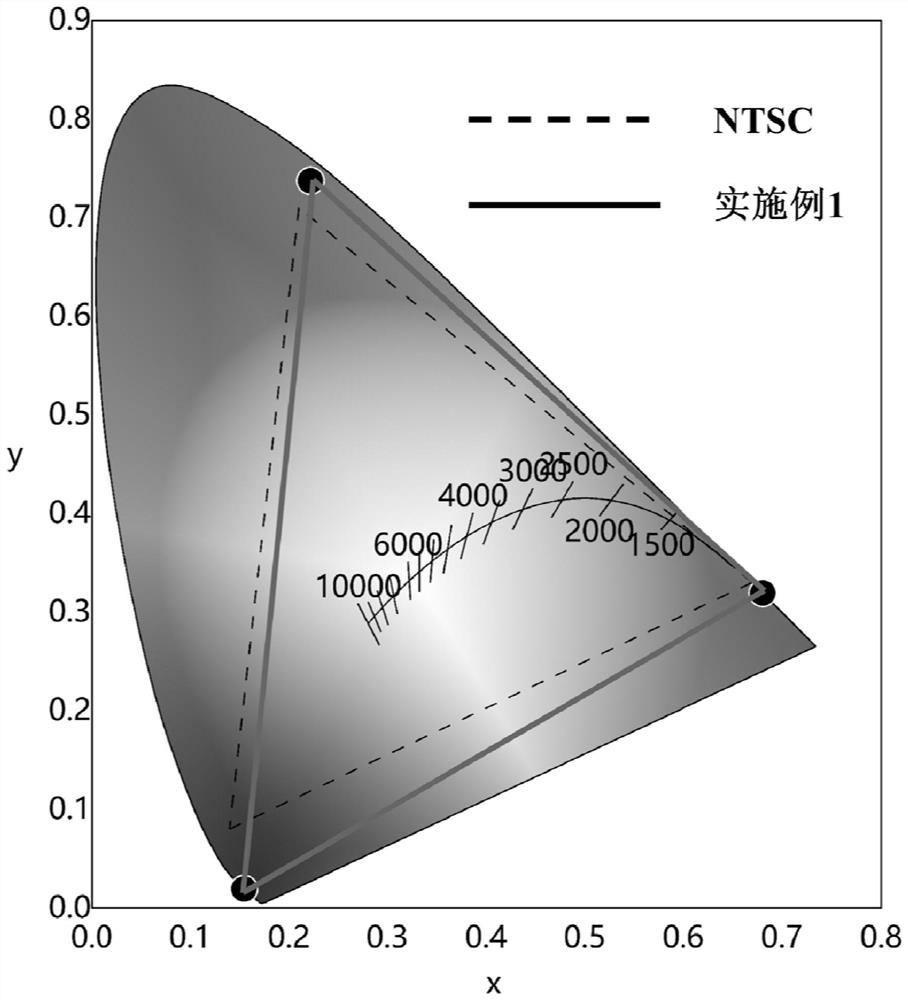

[0036] 0.3g CaAlSiN 3 -LiSi2 N 3 -Si 2 N 2 O phosphor (made of CaAlSiN 3 , Li Si 2 N 2 and Si 2 N 2 O was prepared by weighing and grinding at 1700°C for 12 h according to the molar ratio of 0.5:2:1) and 0.6 g of glass powder (Changzhou Wujin Xinghai Chemical Co., Ltd.) were uniformly ground in an agate mortar, and 1 mL of organic rubber was added [by Terpineol (Shanghai Aladdin Biochemical Co., Ltd., 95%), diethylene glycol butyl ether (Shanghai Aladdin Biochemical Co., Ltd., 98%), ethyl cellulose (Shanghai Aladdin Biochemical Co., Ltd. , 18-22mPa·s) according to the mass ratio of 1:1:1 and then stirred at 80°C for 8h to make] the required orange-red phosphor-glass powder mixed slurry was obtained after uniform mixing. Apply the orange-red fluorescent powder-glass powder mixed slurry evenly on the surface-coated transparent sapphire substrate (that is, the high thermal conductivity ceramic substrate, Zhejiang Crystal Optoelectronics Technology Co., Ltd., 10-30Wm -1 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com