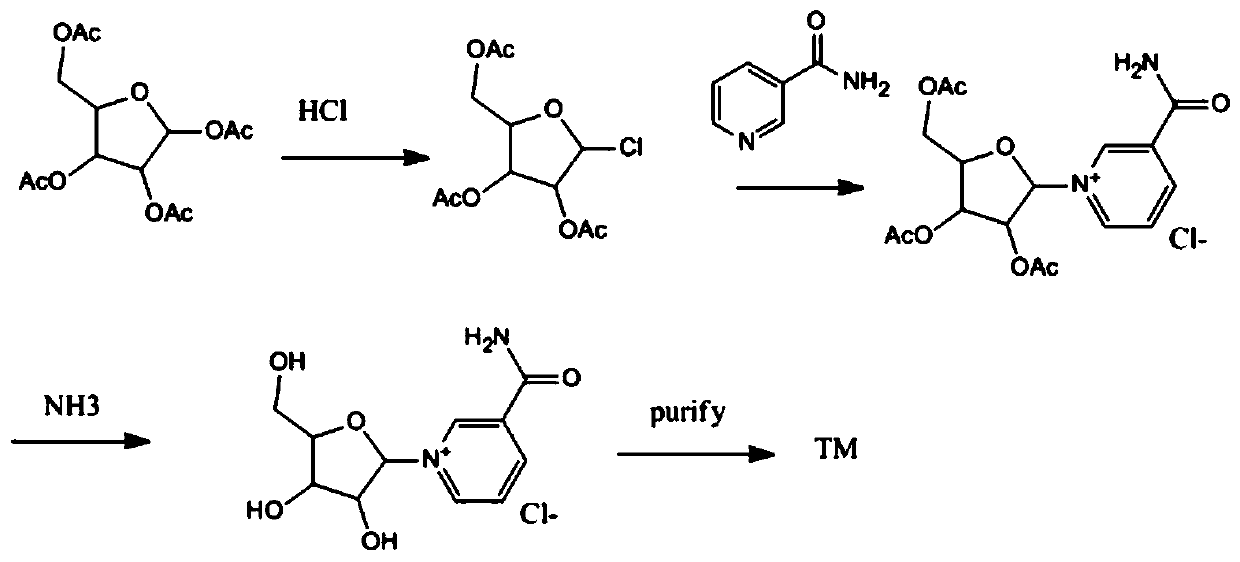

Preparation method of beta-nicotinamide ribose chloride (NRC)

A nicotinamide ribose and chloride technology is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., and can solve the problems of high cost, low yield, difficult handling, etc., and achieves low production cost and high purity. , the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of β-nicotinamide ribose chloride, the steps are as follows:

[0053] a. Chlorination reaction

[0054] Dissolve 2kg of tetraacetylribose (supplied by Wuxi Jingyao Biotechnology Co., Ltd., the same below) in 10L of chloroform, control the temperature in an ice-water bath at 0°C, inject hydrogen chloride gas to saturation, and continue the reaction for 2 hours. TLC monitoring shows that the raw material Disappeared, spin dry chloroform at 30-35°C, collect the evaporated chloroform; add 3L toluene to the reaction system in 4 times for vacuum distillation, water bath temperature 40-45°C, take away the chloroform in the system by vacuum distillation Acetic acid, spin-dried to obtain 1.79 kg of oily triacetyl ribose chloride, with a yield of 96.5%, all of which were directly used in the next step.

[0055] b. Condensation reaction

[0056] Under the protection of nitrogen, add the chlorinated triacetyl ribose and 0.6kg of nicotinamide obtained in the p...

Embodiment 2

[0062] Embodiment 2 (large batch):

[0063] A preparation method of β-nicotinamide riboside, the steps are as follows:

[0064] a. Chlorination reaction

[0065] Dissolve 200kg of tetraacetylribose in 700L of dichloromethane, control the temperature in an ice-water bath at 0°C, pass in hydrogen chloride gas to saturation, and continue the reaction for 2 hours. TLC monitoring shows that the raw materials have disappeared. Evaporate the dichloromethane to dryness at 30-35°C. dichloromethane; 300L toluene was added to the reaction system in 4 times for vacuum distillation, the water bath temperature was 40-45°C, and the acetic acid in the system was taken away by vacuum distillation, and the oil obtained by spin-drying was chlorotriacetyl ribose 183 kg, with a yield of 98.6%, all of which were directly used in the next reaction.

[0066] b. Condensation reaction

[0067] Under the protection of nitrogen, add the chlorinated triacetyl ribose and 60kg of nicotinamide obtained in...

Embodiment 3

[0074] A preparation method of β-nicotinamide riboside, the steps are as follows:

[0075] a. Chlorination reaction

[0076] Dissolve 2kg of tetraacetylribose in 10L of dichloromethane, control the temperature in an ice-water bath at 0°C, and inject hydrogen chloride gas to saturation. TLC monitoring shows that the raw material has disappeared, spin dry the dichloromethane at about 30-35°C, and collect the evaporated dichloromethane. Chloromethane; 3L of toluene was added to the reaction system in 4 times for rotary evaporation, the water bath temperature was 40-45°C, and the acetic acid in the system was taken away by vacuum distillation, and the oil obtained by spinning was 1.81 kg of chlorotriacetyl ribose, and the yield was It was 97.6%, all of which were directly used in the next reaction.

[0077] b. Condensation reaction

[0078] Under the protection of nitrogen, add the chlorinated triacetyl ribose and 0.6kg of nicotinamide obtained in the previous step into 3L of ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com