Novel titanium catalyst for polyester and preparation method of novel titanium catalyst

A titanium-based catalyst and catalyst technology, applied in the direction of titanium organic compounds, etc., can solve the problem of unsatisfactory polyester color and luster, achieve good color and reduce side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

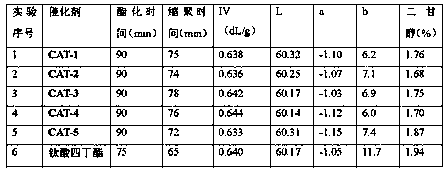

Examples

preparation example Construction

[0028] A kind of preparation method for the novel titanium series catalyst of polyester is characterized in that comprising the steps:

[0029] S1: Add at least two of the difunctionality, trifunctionality and tetrafunctionality compounds into the solvent according to a certain proportion, stir to dissolve all the solids, and obtain a mixed ligand solution;

[0030] S2: Mix and react titanate with the mixed ligand solution prepared in step S1, then add stabilizer and catalyst in turn, remove the replaced monofunctional alcohols and solvents by distillation, add appropriate amount of ethylene glycol to dilute to prepare a solution , which is mainly used in PET, PTT, PBT, PETG, PBS, PES, PEST, PBST, PEAT, PBAT, PCT, PCT, PCTG, PEIT, PEN, polyester elastomer, low melting point polyester, nylon elastomer, polyester In the polymerization process of polyesters such as carbonates and polyurethanes and polymers containing ester bonds, the dissolution temperature is -20-80 °C; the diss...

Embodiment 1

[0033] Citric acid (9.6g, 0.05mol, 0.5eq) and succinic acid (17.7g, 0.15mol, 1.5eq) were added to a round bottom flask, and ethanol (500g) was added to stir and dissolve under nitrogen protection to prepare a mixed ligand solution. Under nitrogen protection and stirring, tetrabutyl titanate (34.0 g, 0.1 mol, 1 eq) was added to the mixed ligand solution, and after half an hour of reaction, it was added to the boiling point of the solvent to react for 4 hours. The solvents ethylene glycol and butanol were removed by rotary evaporation, and then titanium catalyst CAT-1 diluted with ethylene glycol (120 g) to a titanium element content of 4% was added.

Embodiment 2

[0035] The feeding amount is: citric acid (9.6g, 0.05mol, 0.5eq), oxalic acid (13.5g, 0.15mol, 1.5eq), tetrabutyl titanate (34.0g, 0.1mol, 1eq), and the content of titanium element is 4 % titanium catalyst CAT-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com