Preparation method of cathode of the lithium-sulfur battery

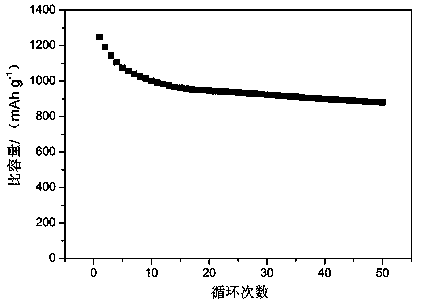

A technology of lithium-sulfur batteries and sulfur electrodes, which is applied in the direction of electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problems of reducing the reactivity of active materials, low battery discharge specific capacity, and reduced battery discharge capacity, so as to improve discharge capacity. The specific capacity, the effect of improving the stability of cycle discharge and reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

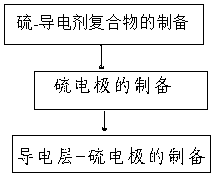

Method used

Image

Examples

Embodiment 1

[0025] Weigh 24g of sulfur and 16g of acetylene black respectively, add sulfur and acetylene black into the ball mill jar, then add absolute ethanol into the ball mill jar, ball mill and mix for 5 hours in an argon protective atmosphere, and the ball mill speed is 240r min -1 , After vacuum drying at 60°C for 7h, the sulfur-acetylene black composite was obtained, and the mass of the sulfur-acetylene black composite was weighed.

[0026] Mix the sulfur-acetylene black compound with Super P carbon black and polyvinylidene fluoride at a mass ratio of 8:1:1, add N-methylpyrrolidone to dissolve the polyvinylidene fluoride, and mix the sulfur-acetylene black compound, Super P P carbon black and polyvinylidene fluoride were mixed to make a slurry, coated on an aluminum foil with a thickness of 20 μm, and dried in vacuum at 90°C for 8 hours to prepare a sulfur electrode.

[0027] After the sulfur electrode was fixed on the micro-plasma spraying robot, the micro-plasma spraying method ...

Embodiment 2

[0031] Weigh 18g of sulfur and 12g of acetylene black respectively, add sulfur and acetylene black into the ball milling jar, then add absolute ethanol into the ball milling jar, and ball mill and mix for 4 hours in an argon protective atmosphere, the ball milling speed is 230r min -1 , After vacuum drying at 60°C for 6h, the sulfur-acetylene black composite was obtained, and the mass of the sulfur-acetylene black composite was weighed.

[0032] Mix the sulfur-acetylene black compound with Super P carbon black and polyvinylidene fluoride at a mass ratio of 8:1:1, add N-methylpyrrolidone to dissolve the polyvinylidene fluoride, and mix the sulfur-acetylene black compound, Super P P carbon black and polyvinylidene fluoride were mixed to make a slurry, coated on an aluminum foil with a thickness of 20 μm, and dried in vacuum at 90°C for 8 hours to prepare a sulfur electrode.

[0033] After the sulfur electrode was fixed on the micro-plasma spraying robot, the micro-plasma sprayin...

Embodiment 3

[0036]Weigh 30g of sulfur and 20g of acetylene black respectively, add sulfur and acetylene black into the ball milling jar, then add absolute ethanol into the ball milling jar, and ball mill and mix for 6 hours in an argon protective atmosphere, the ball milling speed is 250r min -1 , After vacuum drying at 60°C for 8h, the sulfur-acetylene black composite was obtained, and the mass of the sulfur-acetylene black composite was weighed.

[0037] Mix the sulfur-acetylene black compound with Super P carbon black and polyvinylidene fluoride at a mass ratio of 8:1:1, add N-methylpyrrolidone to dissolve the polyvinylidene fluoride, and mix the sulfur-acetylene black compound, Super P P carbon black and polyvinylidene fluoride were mixed to make a slurry, coated on an aluminum foil with a thickness of 20 μm, and dried in vacuum at 90°C for 8 hours to prepare a sulfur electrode.

[0038] After the sulfur electrode was fixed on the micro-plasma spraying robot, the micro-plasma spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com