Method for separating and enriching Baijiu-based flavor substances from wine brewing yellow serofluid

A technology of flavor substances and yellow syrup, applied in the field of wine processing, can solve the problems of large equipment investment, high extraction cost, narrow application range, etc., and achieve the effects of less energy consumption, efficient separation and enrichment, and retention of esterification power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

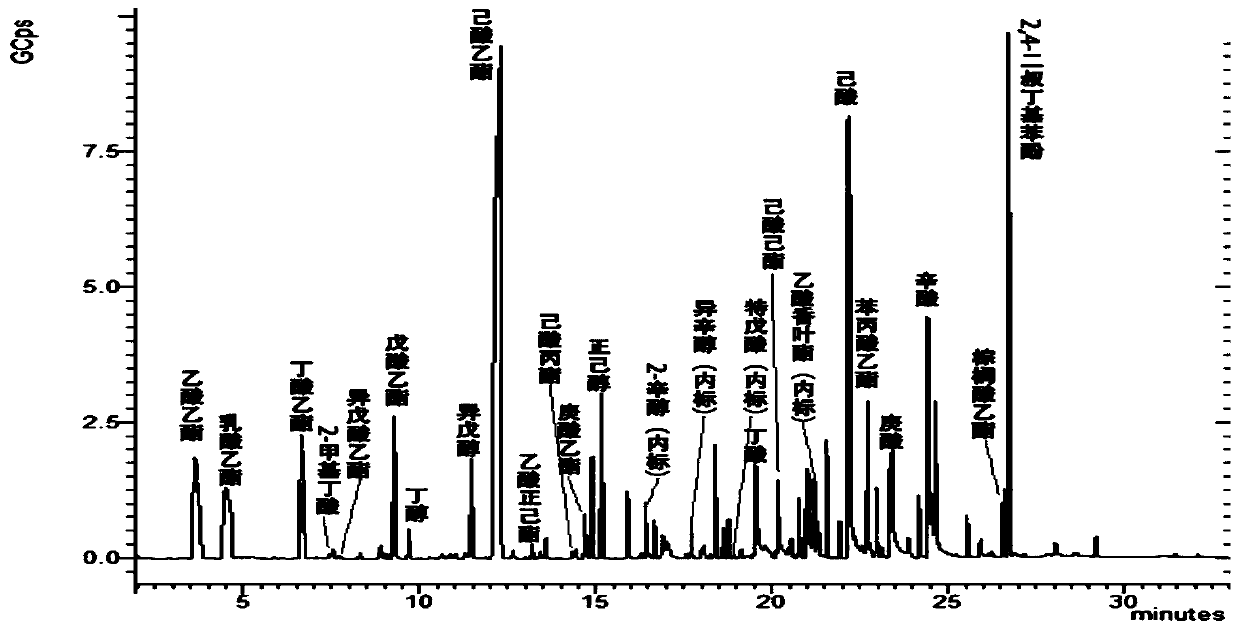

[0046] Example 1: A method for extracting ester flavor substances from wine-making yellow pulp water

[0047] (1) Raw material pretreatment: take 200g of Yanghe Luzhou-flavor wine yellow syrup and centrifuge at 4000r / min for 20min; discard the precipitate, take the supernatant, filter through double-circle qualitative filter paper (medium speed), and refrigerate the filtrate Standby; this step removes most of the solids in the yellow pulp water, including starch, residual sugar, protein, and wine microbial cells or autolyzed matter, to ensure the relative stability of the yellow pulp water system; then centrifuge at 5000r / min for 15min, Discard the precipitate and take the supernatant;

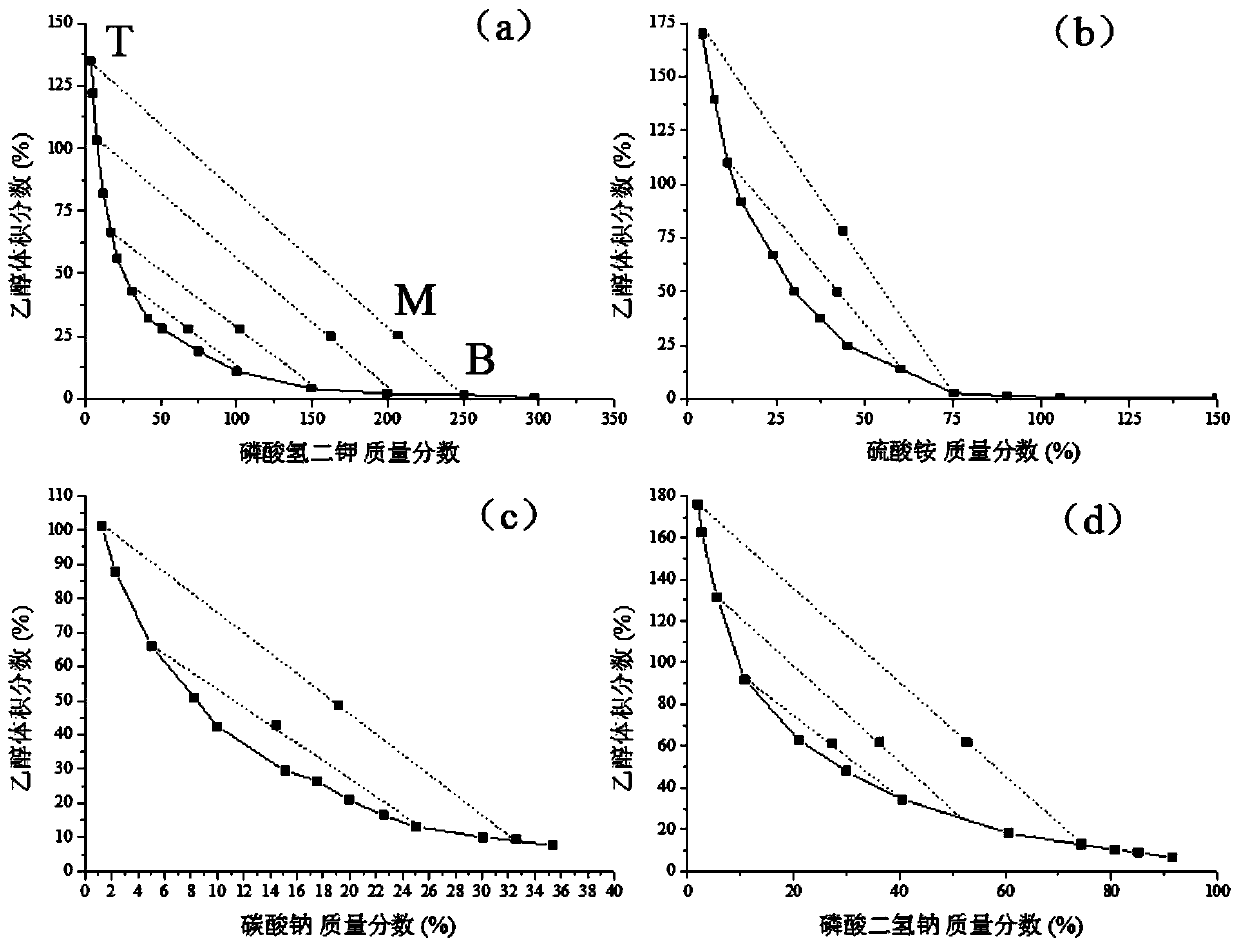

[0048] (2) Add 160g (80% w / w) K to the supernatant 2 HPO 4 ·3H 2 O, 30mL of absolute ethanol to form a two-phase system, stir to promote the full dissolution of salts; let stand to separate layers, and take the upper liquid;

[0049] (3) The upper liquid is further dehydrated and concentra...

Embodiment 2

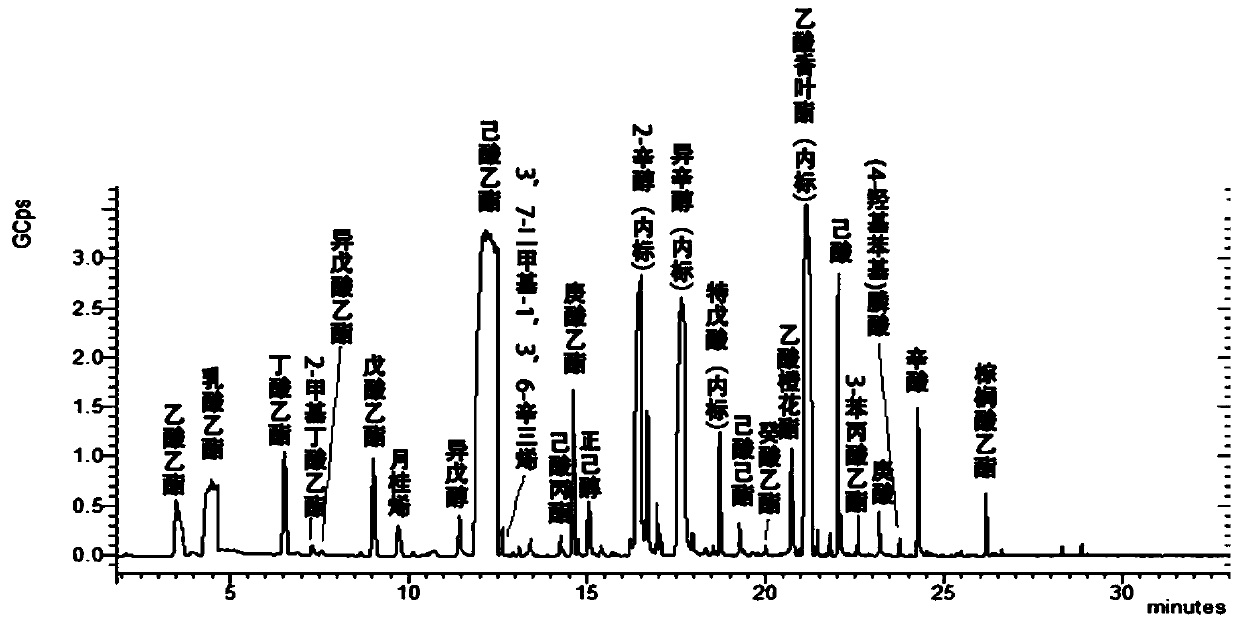

[0055] Embodiment 2: the preparation of a kind of liquor mixing liquid

[0056] (1) Raw material pretreatment: centrifuge 250g of Yanghe Luzhou-flavored yellow syrup water, centrifuge at 4000r / min for 20min; discard the precipitate, take the supernatant, filter through double-circle qualitative filter paper (medium speed), and refrigerate the filtrate until use. This step removes most of the solids in the yellow pulp water, including starch, residual sugar, protein, and wine microbial cells or autolyzed matter, so as to ensure the relative stability of the yellow pulp water system.

[0057] (2) Esterification of yellow pulp water: Take out 200g of yellow pulp water after treatment, select red yeast rice powder as an esterification catalyst, place yellow pulp water in a constant temperature incubator at 31°C for 10 minutes, add 30mL of absolute ethanol, and red yeast rice for esterification 20 g of koji powder (average esterification power 190 mg / g·100 h) was cultured at a con...

Embodiment 3

[0068] Embodiment 3: the preparation of a kind of liquor mixing liquid

[0069] Referring to Example 2, the yellow syrup of Yanghe Luzhou-flavor wine was replaced with the yellow syrup of Shanxi Fenjiu Fenjiu, and other conditions remained unchanged.

[0070] The obtained wine blending liquid: it also has a high recovery rate for ethyl acetate and ethyl lactate, the main flavor components of the fragrance-flavored wine, and the total ester content of the blending liquid is more than 53g / L, reaching the standard of the fragrance-flavored wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com