Earthworm reactor with frame composite structure, and sludge treatment method thereof

A composite structure and reactor technology, which is applied in the field of sludge treatment and resource utilization, can solve the problems of long earthworm treatment cycle, large floor area, mosquito breeding, etc., achieve good environmental and social benefits, and small floor space , The effect of short sludge cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

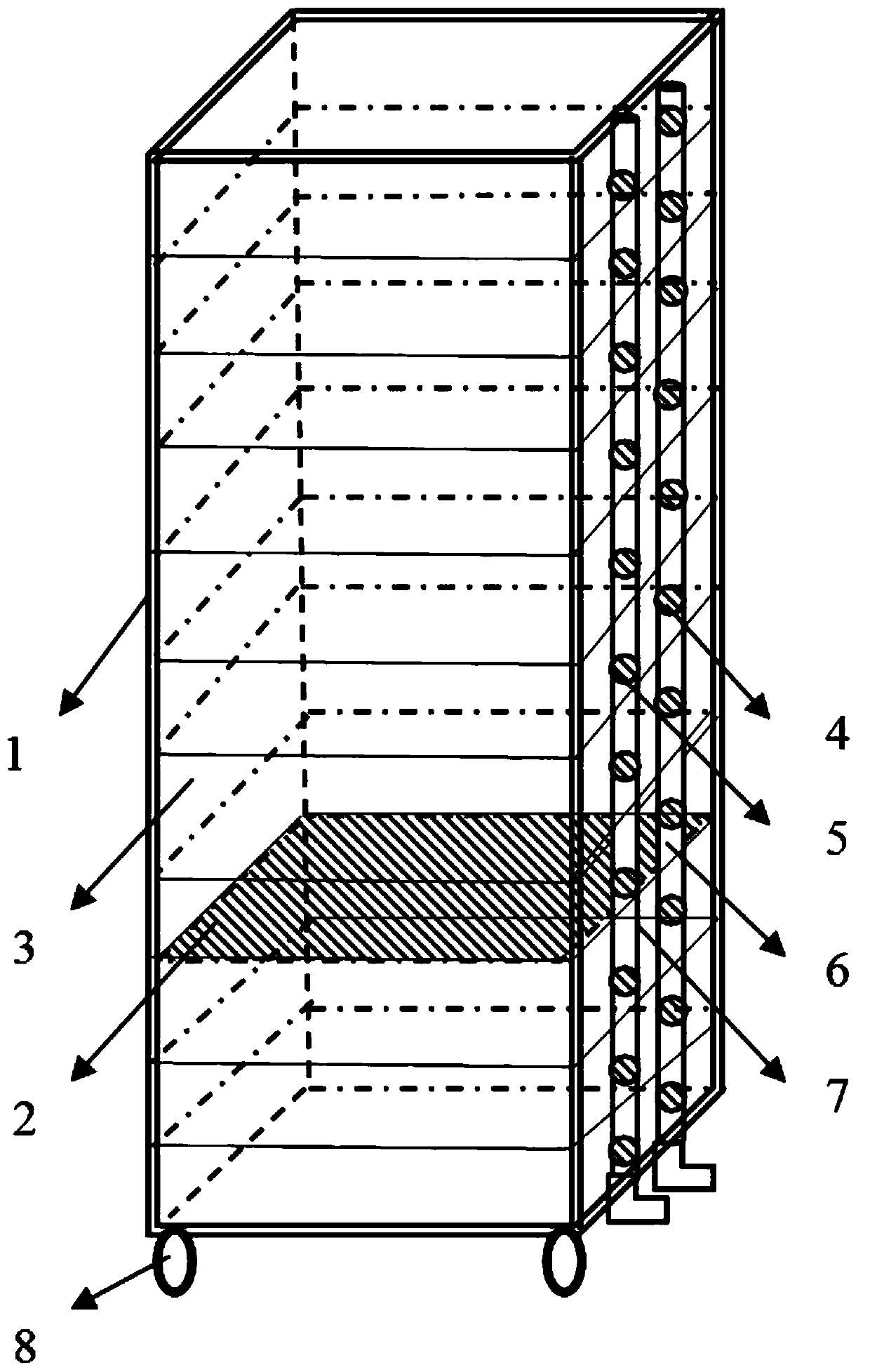

[0036] The present invention adopts such as figure 1 The shown frame composite structure earthworm reactor is used for sludge treatment. The frame composite structure earthworm reactor comprises a main frame 1 and a multi-layer reactor box 3 located in the main frame 1; the bottom of each layer of the main frame 1 is provided with a bottom plate 2, and the bottom of the main frame 1 is provided with universal wheels 8; The reactor box 3 is movably arranged on the bottom plate 2 of each floor, and can be drawn out from the main body frame 1 . The main frame 1 is 52cm long, 44cm wide, and 230cm high, with 15 layers in total, and each layer is 15cm high. The main frame 1 can carry 15 reactor boxes 3 (standardized worm composting boxes), covering an area of about 0.23m 2 .

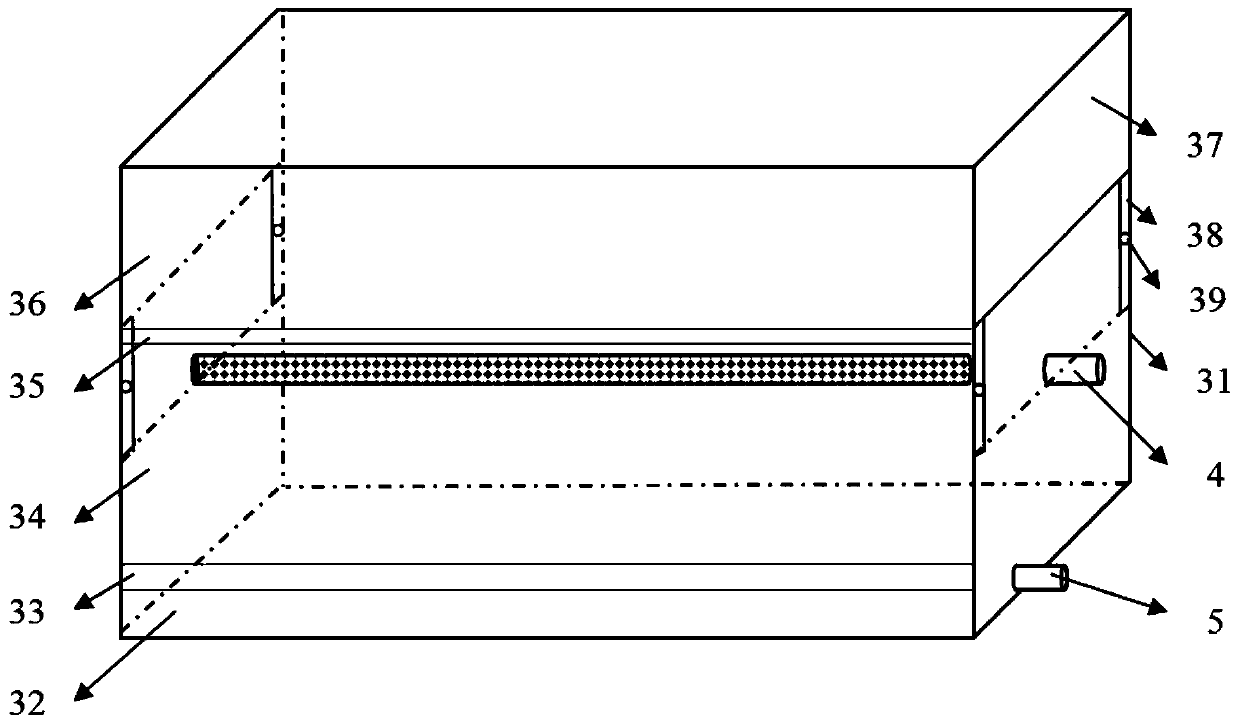

[0037] Aeration pipe 4 and filtrate collection pipe 5 are arranged in the reactor box body 3 of each layer; One side of main body frame 1 is respectively provided with the aeration air supply pipe 6 that ...

Embodiment 2

[0044] The earthworm reactor with frame composite structure is the same as that in Example 1. Using the above-mentioned frame composite structure earthworm reactor to treat municipal sludge in a certain place, the specific steps are:

[0045] Put 2 kg of adult Eisenia annulus into the earthworm habitat bed in each standardized earthworm compost bin, place it under the condition of 18-28 ℃ and avoid light, and cultivate it for 3 days. During this period, water is sprayed on the surface of the earthworm habitat bed every day to keep the humidity. A total of 4 parts of municipal sludge with a moisture content of 87% were added with conditioner A, crushed straw and vermicompost, B, crushed straw and cow dung, C, crushed straw and perishable garbage, and D, crushed straw and blue-green algae. The amount added was the weight of the sludge to be treated 5% and 15% of the earthworm leachate, and then put into the bacterial liquid processed by earthworm leachate, mix well and then deco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com