Impact-resistant compressed carbon fiber polymer latex powder composite modified concrete

A fiber polymer and polymer latex technology, which is applied in the field of concrete materials, can solve the problems that the impact resistance and anti-knock performance of concrete cannot be significantly improved, and achieve the effects of facilitating large-scale rapid construction, high toughness, and improving anti-deformation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The invention provides a composite modified concrete with anti-shock compression carbon fiber polymer latex powder. Latex powder 11%-13%; water reducing agent 4.65kg / m3, defoamer 1.16kg / m3, film-forming aid 2.34kg / m3, dispersant 1.56kg / m3 in admixture; among them, the cement with the label of 42.5 For Portland cement or ordinary Portland cement, medium river sand with a fineness modulus of 2.6-3.0 is used for sand; graded crushed stone with a maximum particle size of no more than 20mm is used for stone; FDN high-efficiency water reducer mother liquor is used for water reducing agent ; The defoaming agent is metal soap-type general defoaming agent; the film-forming aid is DN-12 film-forming aid; the dispersant is hydroxyethyl cellulose dispersant.

[0019] The batching ratio and specific components of the carbon fiber-polymer latex powder composite modified concrete involved in this embodiment are: the water-cement ratio (the mass ratio of the amount of water in the conc...

Embodiment 2

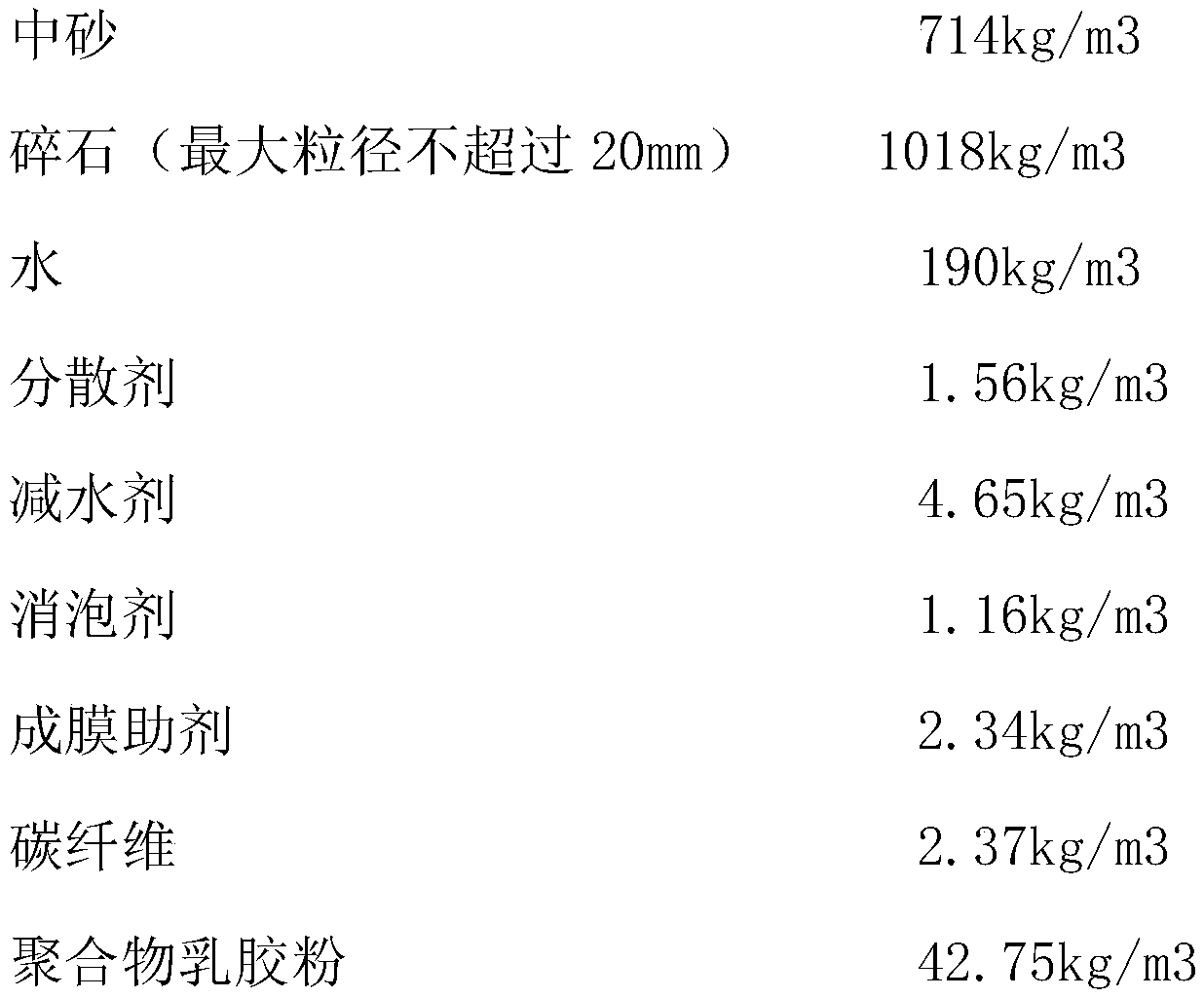

[0035] The batching ratio and specific components of the carbon fiber-polymer latex powder composite modified concrete involved in this embodiment are: the water-cement ratio is 0.49, the carbon fiber volume ratio is 0.2%, the polymer volume ratio is 12%, and the carbon fiber volume ratio is 0.15%. , The sand rate is 34%. specifically available

[0036]

[0037] The preparation method of the carbon fiber-polymer latex powder composite modified concrete that this example involves may further comprise the steps:

[0038] The first step is to determine the mix ratio of concrete, the mixing ratio of carbon fiber and latex powder: according to the required concrete grade, use the trial mix method to determine the mix ratio of concrete materials;

[0039] The second step is to prepare the required materials: prepare the required sand, stone, cement, carbon fiber and latex powder according to the material mix ratio of carbon fiber-polymer latex powder composite modified concrete;...

Embodiment 3

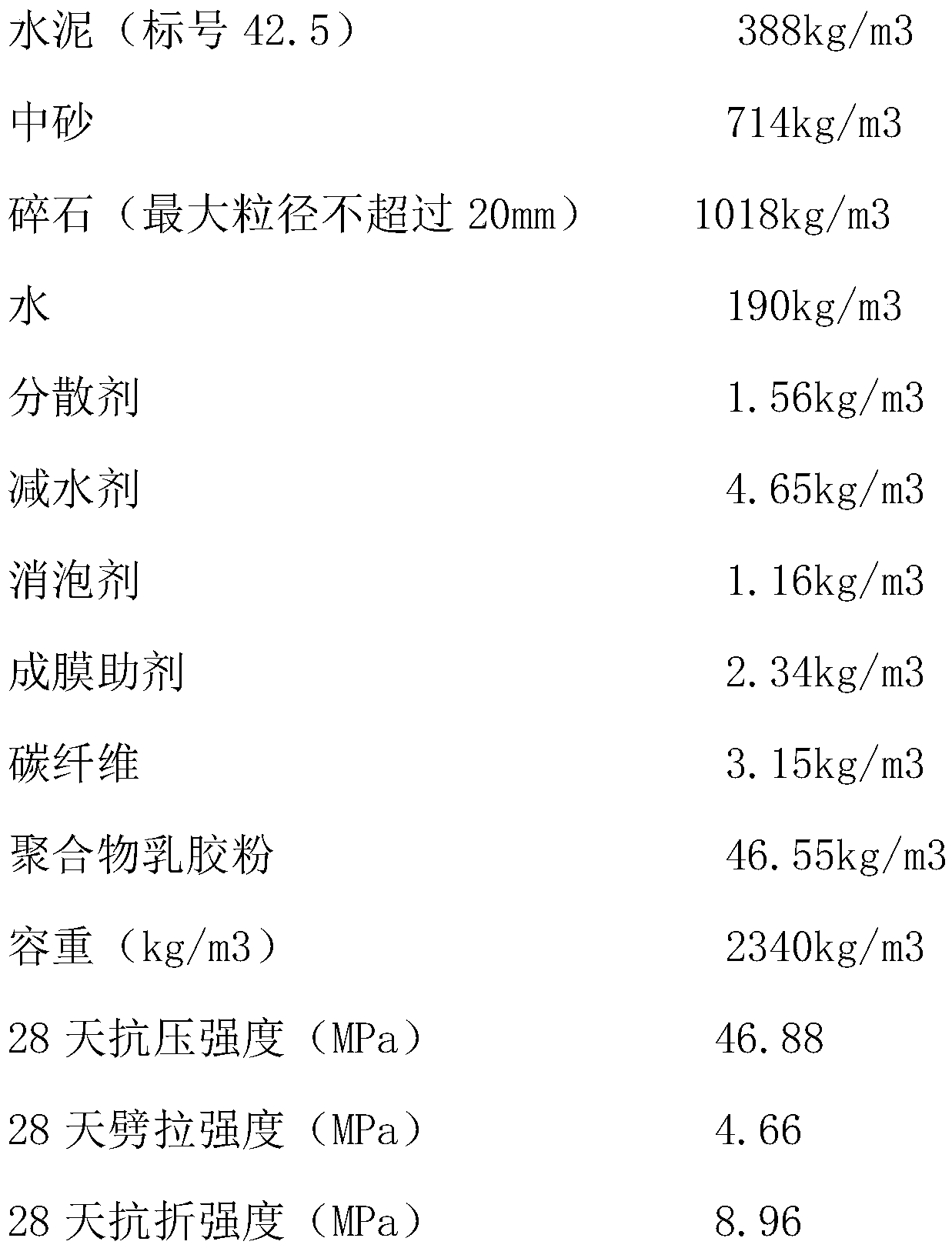

[0045] The batching ratio and specific components of the carbon fiber-polymer latex powder composite modified concrete involved in this embodiment are: the water-cement ratio is 0.49, the carbon fiber volume ratio is 0.25%, the polymer volume ratio is 13%, and the carbon fiber volume ratio is 0.15%. , The sand rate is 34%. specifically available

[0046]

[0047]

[0048]The preparation method of the carbon fiber-polymer latex powder composite modified concrete that this example involves may further comprise the steps:

[0049] The first step is to determine the mix ratio of concrete, the mixing ratio of carbon fiber and latex powder: according to the required concrete grade, use the trial mix method to determine the mix ratio of concrete materials;

[0050] The second step is to prepare the required materials: prepare the required sand, stone, cement, carbon fiber and latex powder according to the material mix ratio of carbon fiber-polymer latex powder composite modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com