Nano-composite heat insulation plate and preparation method thereof

A nano-composite, thermal insulation board technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of large holes, high production costs, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

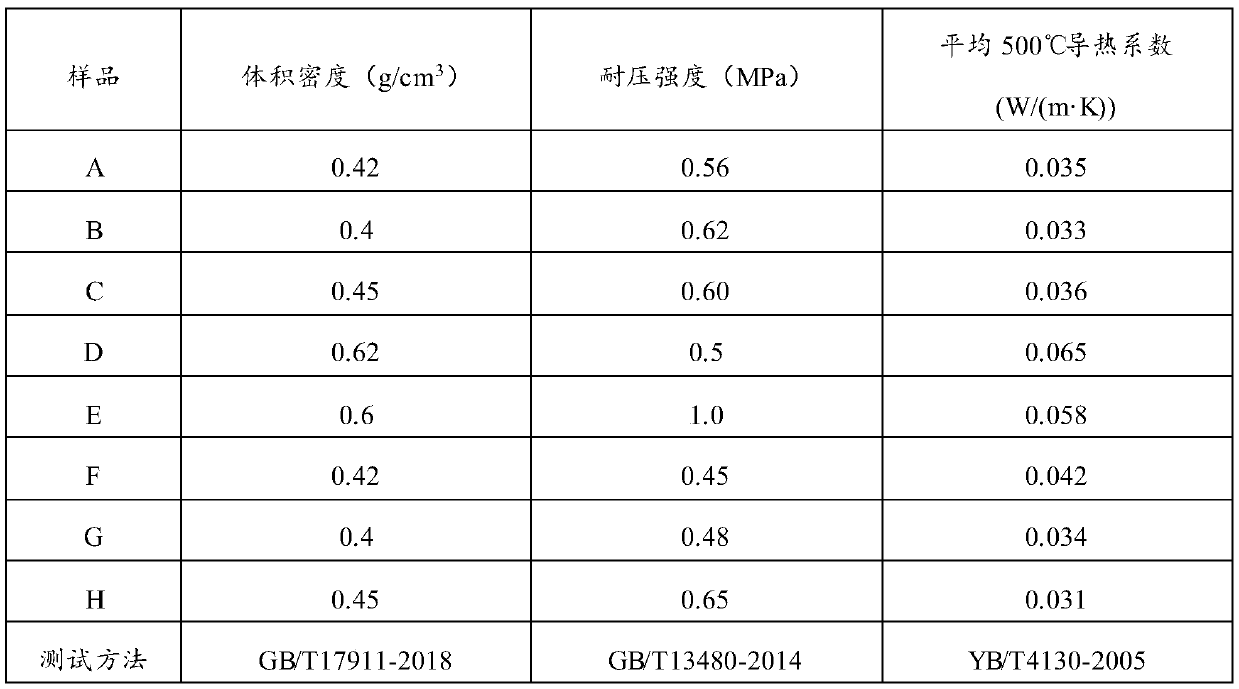

Examples

preparation example Construction

[0029]The present invention also provides a method for preparing the above-mentioned nanocomposite heat insulation board, comprising: S1) combining silicon dioxide with a particle size of 20-30nm, silicon dioxide with a particle size of 400-600nm, expanded perlite, infrared shading mixing agent and inorganic refractory fiber to obtain a mixture; S2) spraying the inorganic adhesive into the mixture, continuing to stir after spraying, and pressing and molding to obtain a nanocomposite heat insulation board.

[0030] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0031] Mix and stir silicon dioxide with a particle size of 20-30nm, silicon dioxide with a particle size of 400-600nm, expanded perlite, an infrared light-shielding agent and an inorganic refractory fiber to obtain a mixture; the silicon dioxide, expanded perlite, The infrared light shielding agent and the inorganic refractory fiber...

Embodiment 1

[0038] Weigh 30 parts by weight of silicon dioxide powder with a particle size of 20-30nm, 40 parts by weight of silicon dioxide powder with a particle size of 400-600nm, 10 parts by weight of expanded perlite, 10 parts by weight of infrared light-shielding agent and 2 parts by weight of inorganic refractory fiber Add to the mixer, where the bulk density of expanded perlite is 60kg / m 3 , the infrared opacifying agent is silicon carbide with a particle size of 3 μm, and the inorganic refractory fiber is a ceramic fiber with a diameter of 4 μm and an average length of 15 mm. Turn on the mixer, the stirring speed is 400rpm, and the stirring time is 15min. After the materials are evenly stirred, stop stirring, and then spray 8 parts by weight of silica sol with a concentration of 30% into the mixer. After the spraying is completed, turn on the mixer with a stirring speed of 300 rpm and a stirring time of 5 minutes. After the stirring is completed, the materials are transported in...

Embodiment 2

[0040] Weigh 40 parts by weight of silicon dioxide powder with a particle size of 20-30nm, 30 parts by weight of silicon dioxide powder with a particle size of 400-600nm, 10 parts by weight of expanded perlite, 10 parts by weight of infrared light-shielding agent and 5 parts by weight of inorganic refractory fiber Add to the mixer, where the bulk density of expanded perlite is 70kg / m 3 , the infrared opacifying agent is titanium dioxide with a particle size of 4 μm, and the inorganic refractory fiber is an alkali-free glass fiber with a diameter of 7 μm and an average length of 8 mm. Turn on the mixer, the stirring speed is 500rpm, and the stirring time is 12min. After the materials are evenly stirred, stop stirring, and then spray 5 parts by weight of silica sol with a concentration of 40% into the mixer. After the spraying is completed, start the mixer with a stirring speed of 350 rpm and a stirring time of 4 minutes. After the stirring is completed, the materials are trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com