Silicon substrate etching solution

A technology for etching solution and silicon substrate, which is applied in the direction of surface etching composition, chemical instrument and method, etc., can solve the problems of reducing the etching speed of silicon oxide film, abnormality, and bad pattern, etc., so as to improve the etching selectivity ratio and not easy to decompose , the effect of preventing decomposition and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0071] Composition of silicon substrate etching solution

[0072] Table 1 below shows the composition of the silicon substrate etching solution according to the embodiment.

[0073] Table 1

[0074] Classification Silicon additive (ppm) Fluorinated compounds (ppm) Example 1 500 - Example 2 2000 - Example 3 1000 - Example 4 800 - Example 5 800 - Example 6 800 - Example 7 800 - Example 8 800 500

[0075] The silicon substrate etching solutions of Examples 1 to 8 contained 85% by weight of phosphoric acid and the balance of water, and contained silicon additives and fluorine-containing compounds in ppm units described in Table 1.

[0076] In Example 8, ammonium fluoride was used as the fluorine-containing compound.

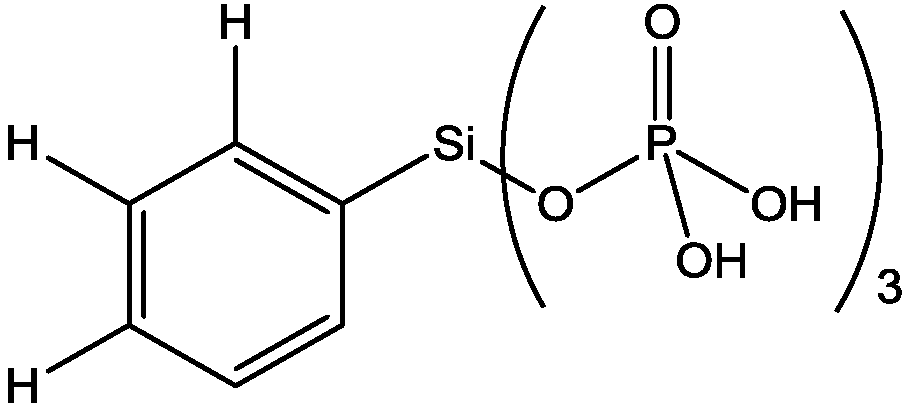

[0077] The silicon additive used in the silicon substrate etching solutions of Examples 1 to 8 is represented by Chemical Formula 1 having functional groups shown in Table 2 below.

[0078] C...

experiment example 2

[0104] Composition of silicon substrate etching solution

[0105] Table 5 below shows the composition of the silicon substrate etching solution according to the embodiment.

[0106] table 5

[0107] Classification Silicon additive (ppm) Fluorinated compounds (ppm) Example 9 500 - Example 10 2000 - Example 11 1000 - Example 12 800 - Example 13 800 - Example 14 800 - Example 15 800 - Example 16 800 500

[0108] The silicon substrate etching solutions of Examples 9 to 16 contained 85% by weight of phosphoric acid and the balance of water, and contained silicon additives and fluorine-containing compounds in ppm units shown in Table 5.

[0109] In Example 16, hydrogen fluoride was used as the fluorine-containing compound.

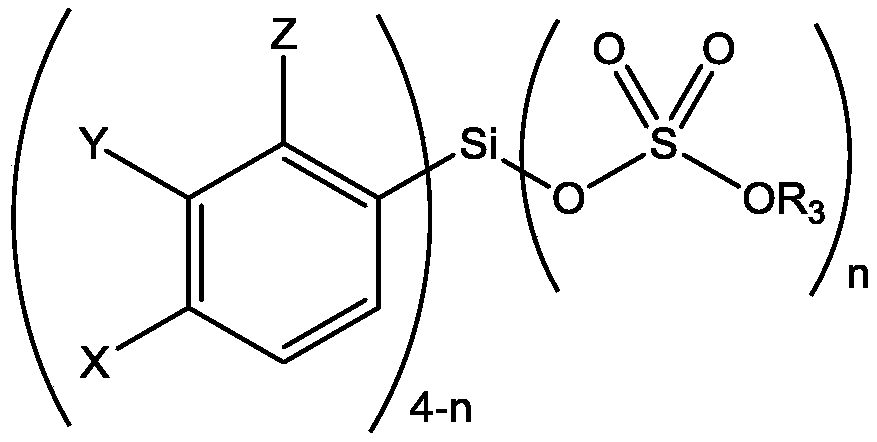

[0110] The silicon additive used in the silicon substrate etching solutions of Examples 9 to 16 is represented by Chemical Formula 2 having functional groups shown in Table 6 below.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com